Operator’s manual @ 601 59

GB

sample weight and an average-size wheel. Perform the sensitivity calibration procedure

if necessary.

USE OF GREASE

Greasing the wheel balancer

The rotating parts of the wheel balancers are the motor and the balancing shaft. The bearing

of those components must therefore be checked periodically by the operator and greased

when necessary. If the machine is used frequently (more than two hours a day), check the

bearing every year; if the machine is not used frequently, the check can be performed

every two years. The bearing can be opened for inspection: insert a screwdriver and check

the subsequent sound to test it. The bearing acts as a locking support, therefore the

grease cannot be easily changed or removed. In addition, the rotation speed is not high

for the machine, so the grease does not need to be changed. If you see that operation

is anomalous or that the bearing is noisy, replace the bearing. If the customer confirms

the bearing has been replaced, replace only the grease, then remove the bearing, open

the dust sealing ring, and add grease (XHP103). These operations must be performed

under the guidance of a professional. After replacing the bearing calibrate the machine.

If the operation was performed correctly, the machine accuracy will be altered, therefore

reposition the dust sealing ring, re-assemble the machine and adjust again.

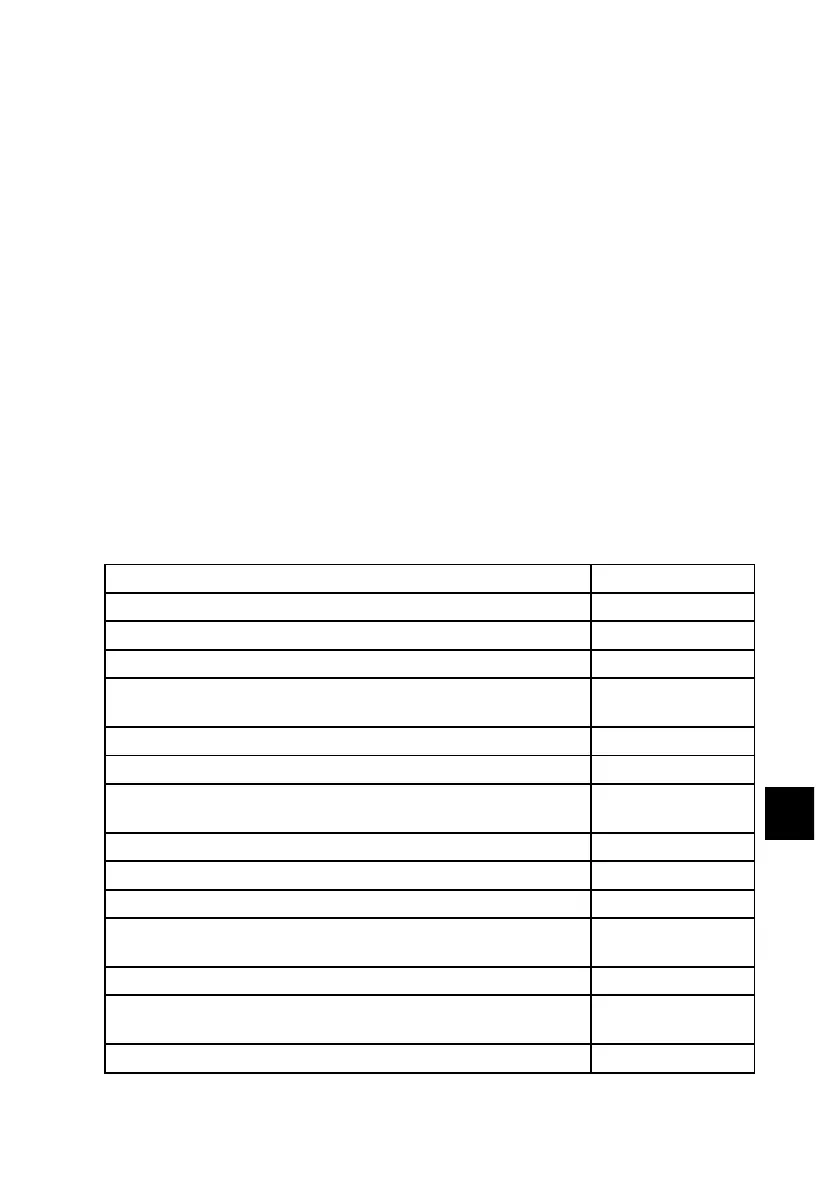

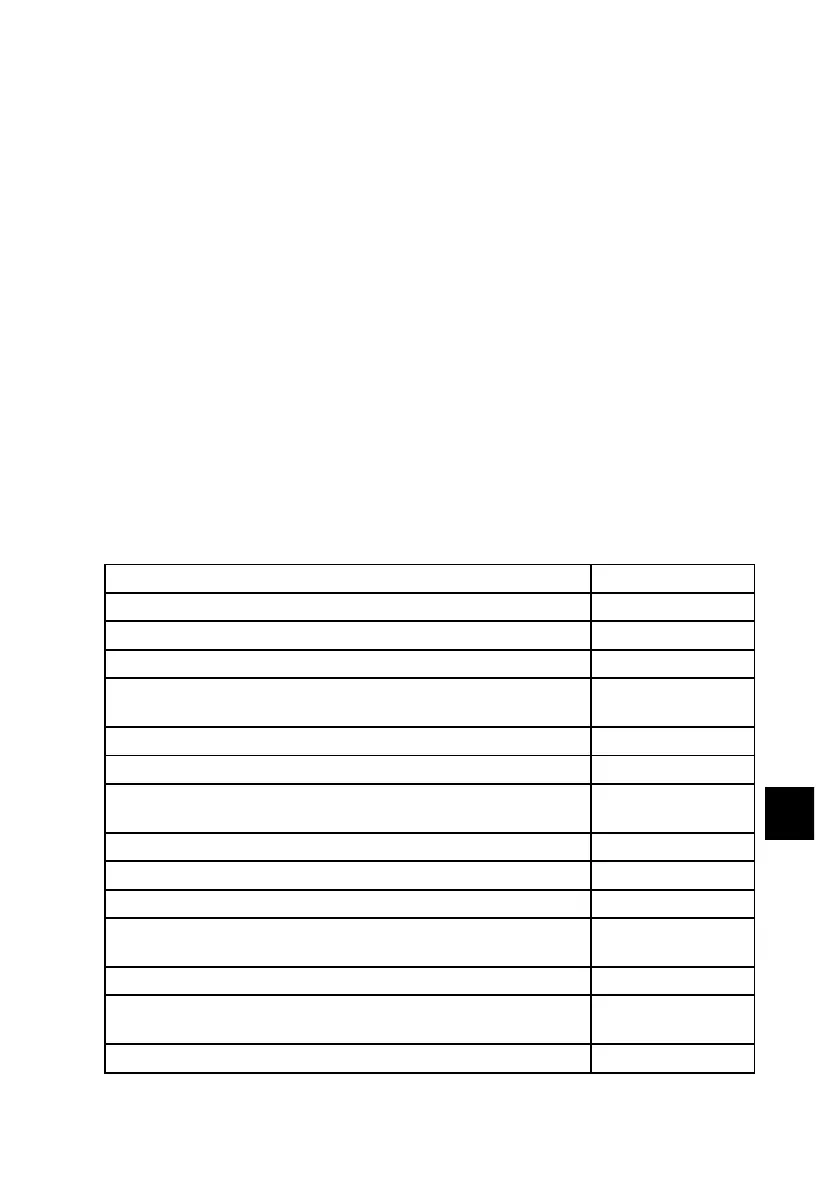

Technical safety sheet for using grease in the wheel balancer

Mobilgrease XHP 103

NLGI Grade

3

Thickener Type Li-complex

Colour Dark blue

Penetration in manufactured material 25ºC , ASTM D 217,

mm/10

235

Dropping Point, ºC , ASTM D 2265

280

Basic oil viscosity, ASTM D 445, cSt @ 40ºC

100

Penetration consistency change, ASMT D 1831 (grease mechanical

stability), mm/10

10

4 ball test, impression diam., ASTM D 2266, mm

0.5

4 ball test, weld load, ASTM D 2509, Kg

315

Timken OK load test, ASTM D 2509, lb

45

Oxidation stability, bomb method, ASTM D 942, pressure drop

after 100 hours, kPa

35

Corrosion Prevention, ASTM D 1743

Passed

Emcor Rust, IP 220, washout using acidic water

0

Rust Protection, IP 220-mod, washout using distilled water

0

Loading...

Loading...