Unpacking and Setting Up the CompuCarve System

1. Remove the top packaging foam: After opening the shipping box,

carefully remove the top molded foam packing from the machine.

Located in the top tray are items B through K listed above.

2. Remove the machine from box: With a helper, lift out the machine

and place it on a sturdy table or bench. Fold down the Outfeed Support

Tables. Remove the plastic film covering the top clear safety cover.

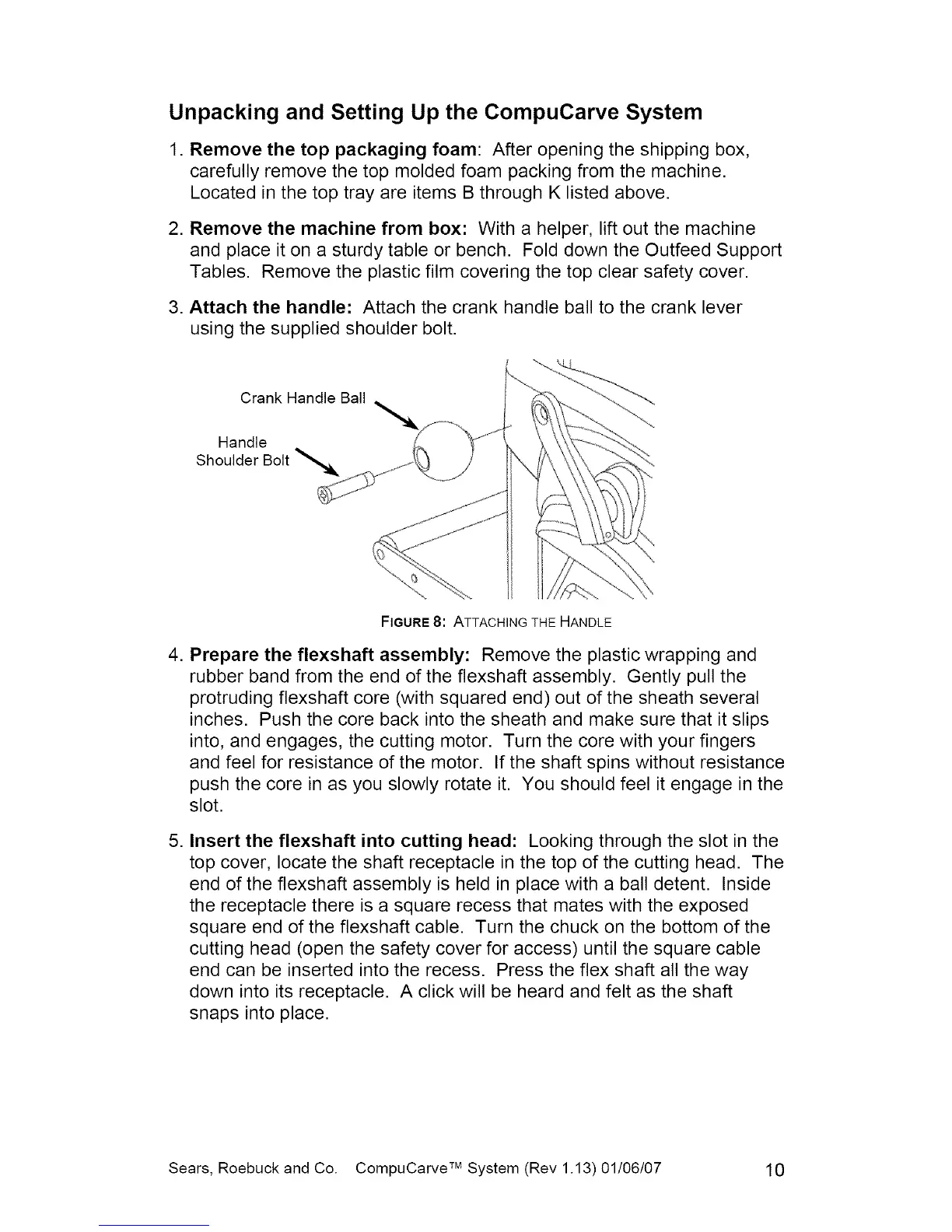

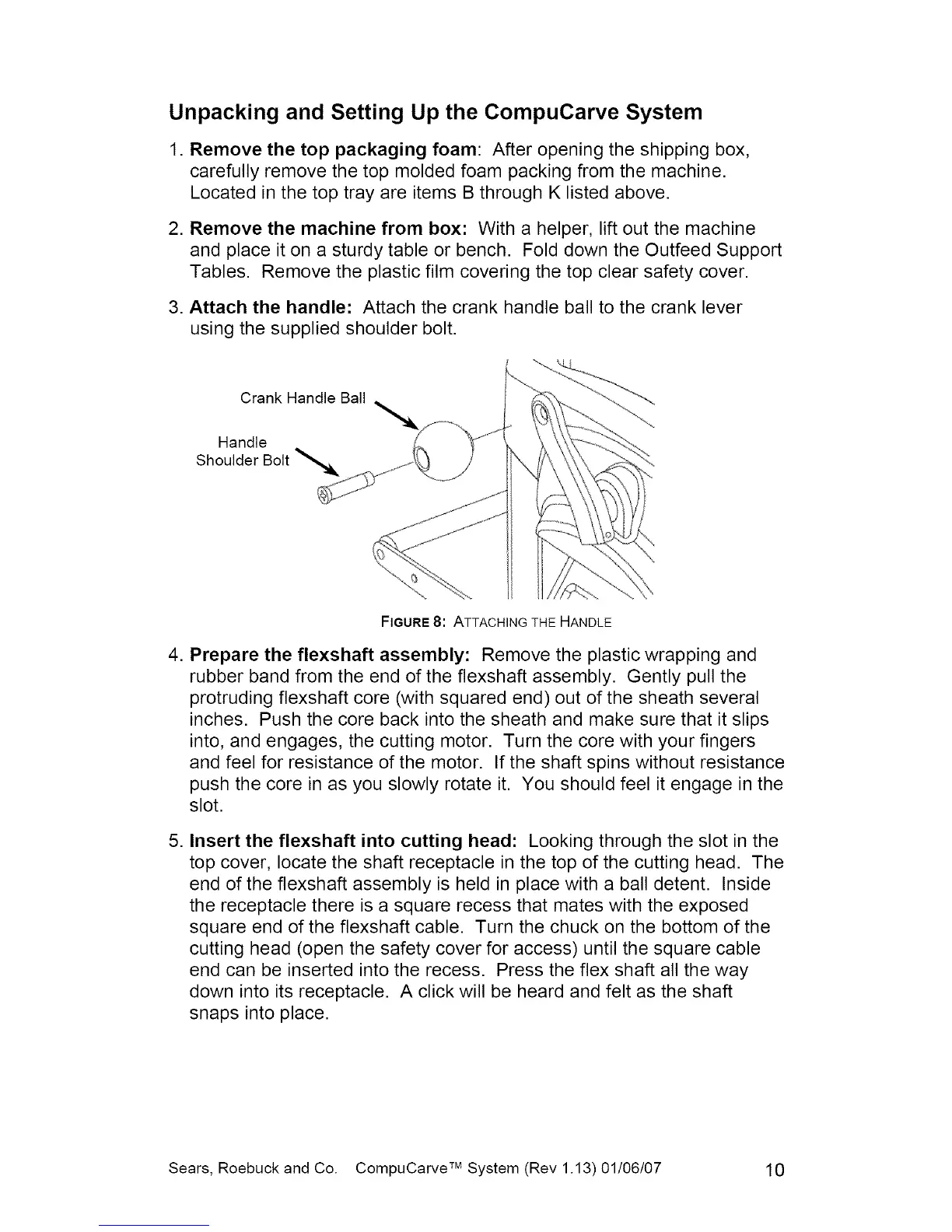

3. Attach the handle: Attach the crank handle ball to the crank lever

using the supplied shoulder bolt.

Crank Handle Ball

Handle

Shoulder Bolt

FIGURE 8: ATTACHING THE HANDLE

4. Prepare the flexshaft assembly: Remove the plastic wrapping and

rubber band from the end of the flexshaft assembly. Gently pull the

protruding flexshaft core (with squared end) out of the sheath several

inches. Push the core back into the sheath and make sure that it slips

into, and engages, the cutting motor. Turn the core with your fingers

and feel for resistance of the motor. If the shaft spins without resistance

push the core in as you slowly rotate it. You should feel it engage in the

slot.

5. Insert the flexshaft into cutting head: Looking through the slot in the

top cover, locate the shaft receptacle in the top of the cutting head. The

end of the flexshaft assembly is held in place with a ball detent. Inside

the receptacle there is a square recess that mates with the exposed

square end of the flexshaft cable. Turn the chuck on the bottom of the

cutting head (open the safety cover for access) until the square cable

end can be inserted into the recess. Press the flex shaft all the way

down into its receptacle. A click will be heard and felt as the shaft

snaps into place.

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 10

Loading...

Loading...