WARNING: Always unplug machine before attempting any

troubleshooting or maintenance on the machine.

Checking the Board Sensor: There are several reasons why the

machine will prompt the user to "Check the Board Sensor".

o There is dust obscuring the sensor. Please see the next section

titled "Cleaning of the Board Sensor" for details on how to address

this situation.

o There are existing features on the workpiece, like holes or other

carved features, which prevent the sensor from tracking the top

surface. This can be fixed by placing a piece of masking tape over

the feature.

o The material is too transparent or reflective. This can be fixed by

placing a piece of masking tape on the surface of the workpiece

along the line that the sensor traces while measuring. This

generally requires placing tape across the width and length of the

workpiece.

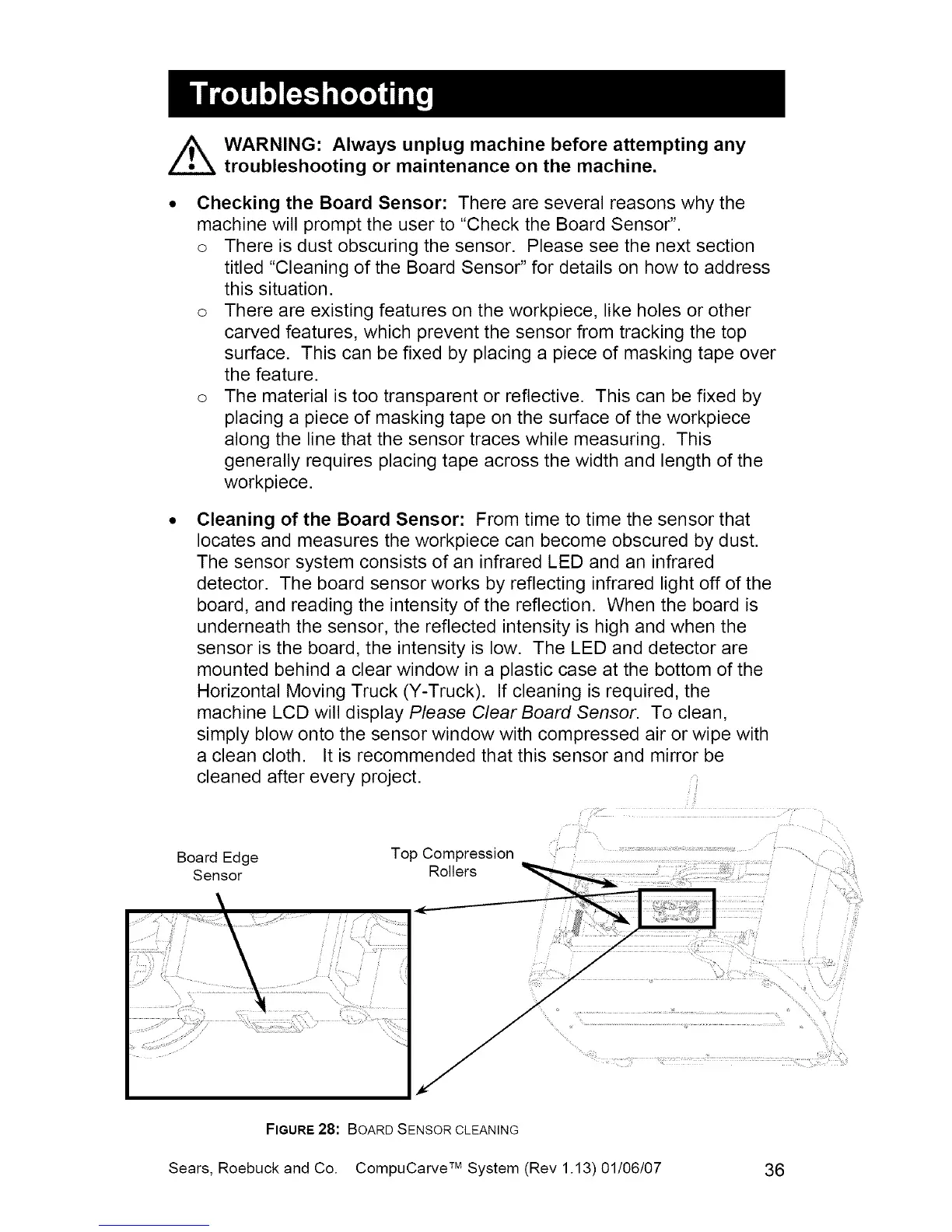

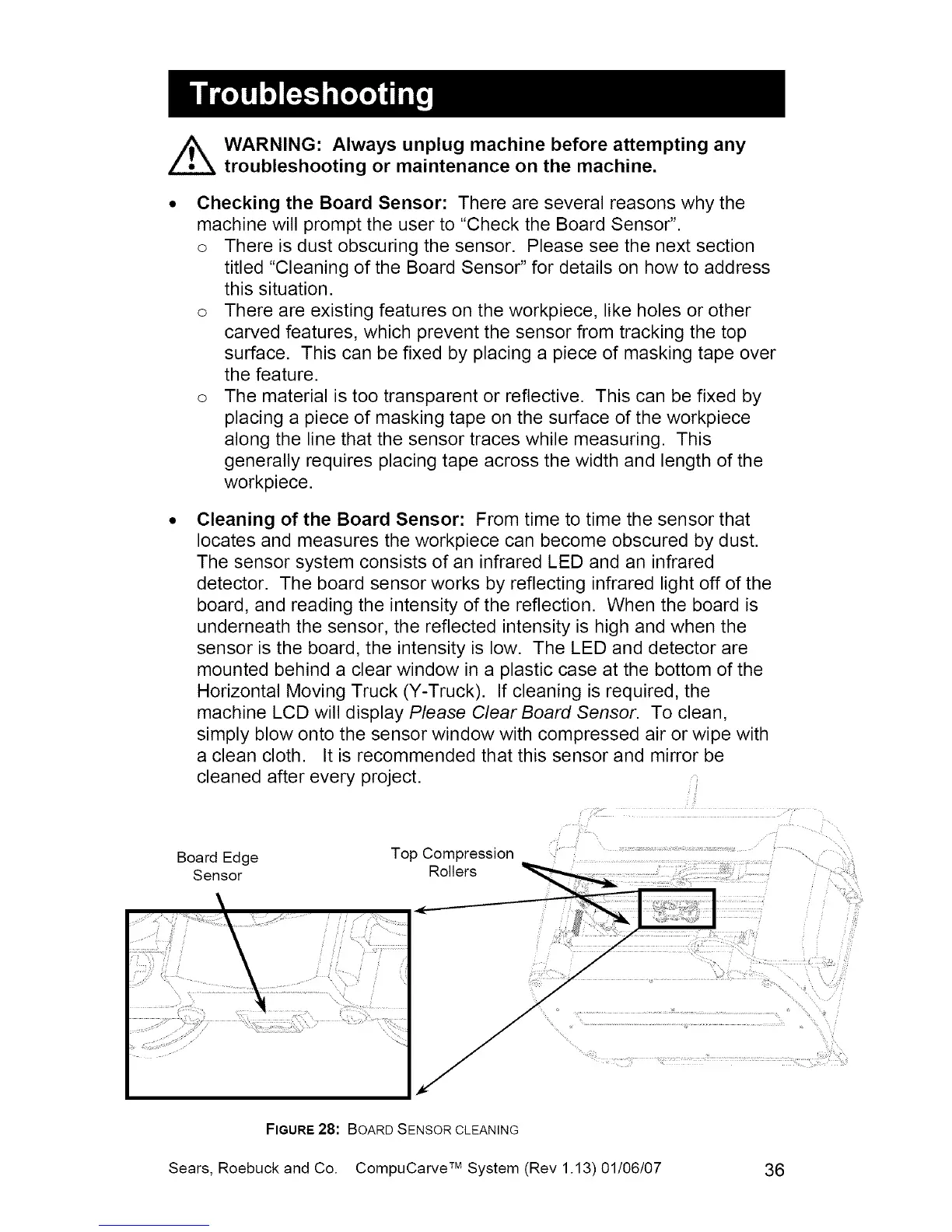

Cleaning of the Board Sensor: From time to time the sensor that

locates and measures the workpiece can become obscured by dust.

The sensor system consists of an infrared LED and an infrared

detector. The board sensor works by reflecting infrared light off of the

board, and reading the intensity of the reflection. When the board is

underneath the sensor, the reflected intensity is high and when the

sensor is the board, the intensity is low. The LED and detector are

mounted behind a clear window in a plastic case at the bottom of the

Horizontal Moving Truck (Y-Truck). If cleaning is required, the

machine LCD will display Please Clear Board Sensor. To clean,

simply blow onto the sensor window with compressed air or wipe with

a clean cloth. It is recommended that this sensor and mirror be

cleaned after every project.

Board Edge Top Compression

Sensor

I

FIGURE 28: BOARD SENSOR CLEANING

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 36

Loading...

Loading...