Troubleshooting the Board Sensor

If the board sensor error cannot be resolved by cleaning the sensor as

in the above steps you can further troubleshoot the problem. To check

the status of the board edge sensor, go to the Main Menu-Options-

Sensor Check menu (Item 7). Use the arrow keys to find Board Sensor

on the bottom line of the display and press ENTER. Do the following

checks:

O

O

Load a board lower the head and check the reading displayed on

the LCD. The correct reading should be in the range of 150 to 170.

Check the reading displayed on the LCD when the sensor is not

over a board. The correct reading should be less then 10 and

ideally 0.

Raise the head, so that you can place your hand underneath the

board sensor. Use your hand to drive the Board Sensor reading to

go greater than 50. Quickly remove your hand from under the

sensor. You should see the reading drop immediately to the no

board reading. The correct reading should be less then 10 and

ideally 0.

If any of the checks fail, ensure the sensor is clear of dust and recheck.

If the operation does not improve, contact CompuCarve.

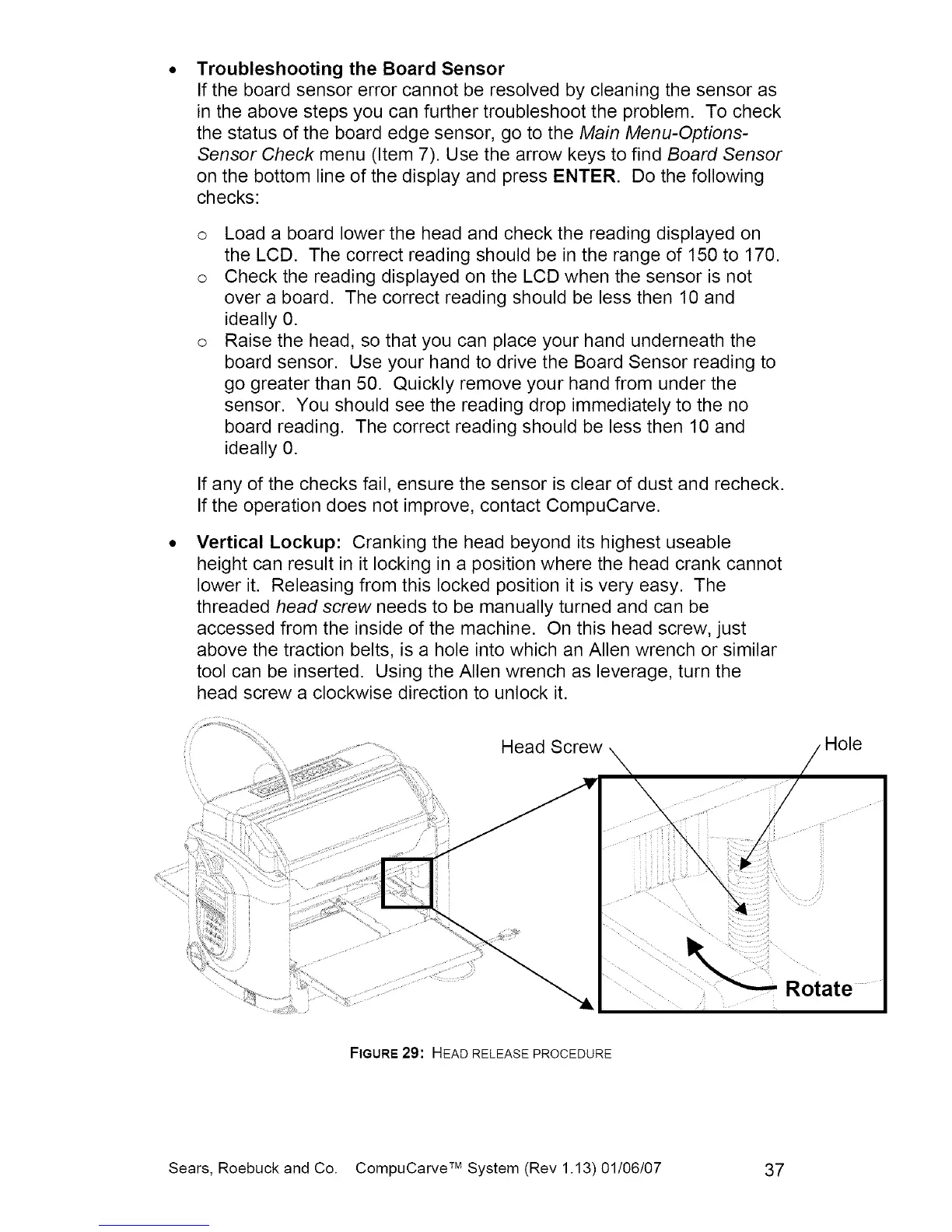

Vertical Lockup: Cranking the head beyond its highest useable

height can result in it locking in a position where the head crank cannot

lower it. Releasing from this locked position it is very easy. The

threaded head screw needs to be manually turned and can be

accessed from the inside of the machine. On this head screw, just

above the traction belts, is a hole into which an Allen wrench or similar

tool can be inserted. Using the Allen wrench as leverage, turn the

head screw a clockwise direction to unlock it.

Head Screw

Hole

i!_i_iiii

Rotate

i

i

FIGURE29: HEAD RELEASE PROCEDURE

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 37

Loading...

Loading...