,

The clutch is intended to load the board against the traction drive

with consistent force. In certain cases the machine can sense if the

workpiece is not loaded enough and repeatably display "Please

Load Board" on the LCD. Most often this decreased loading is

caused by insufficient lubrication of the four vertical corner posts or

the two vertical leadscrews. Please see the Checking the Head

Pressure in the troubleshooting section for the proper lubrication

procedure.

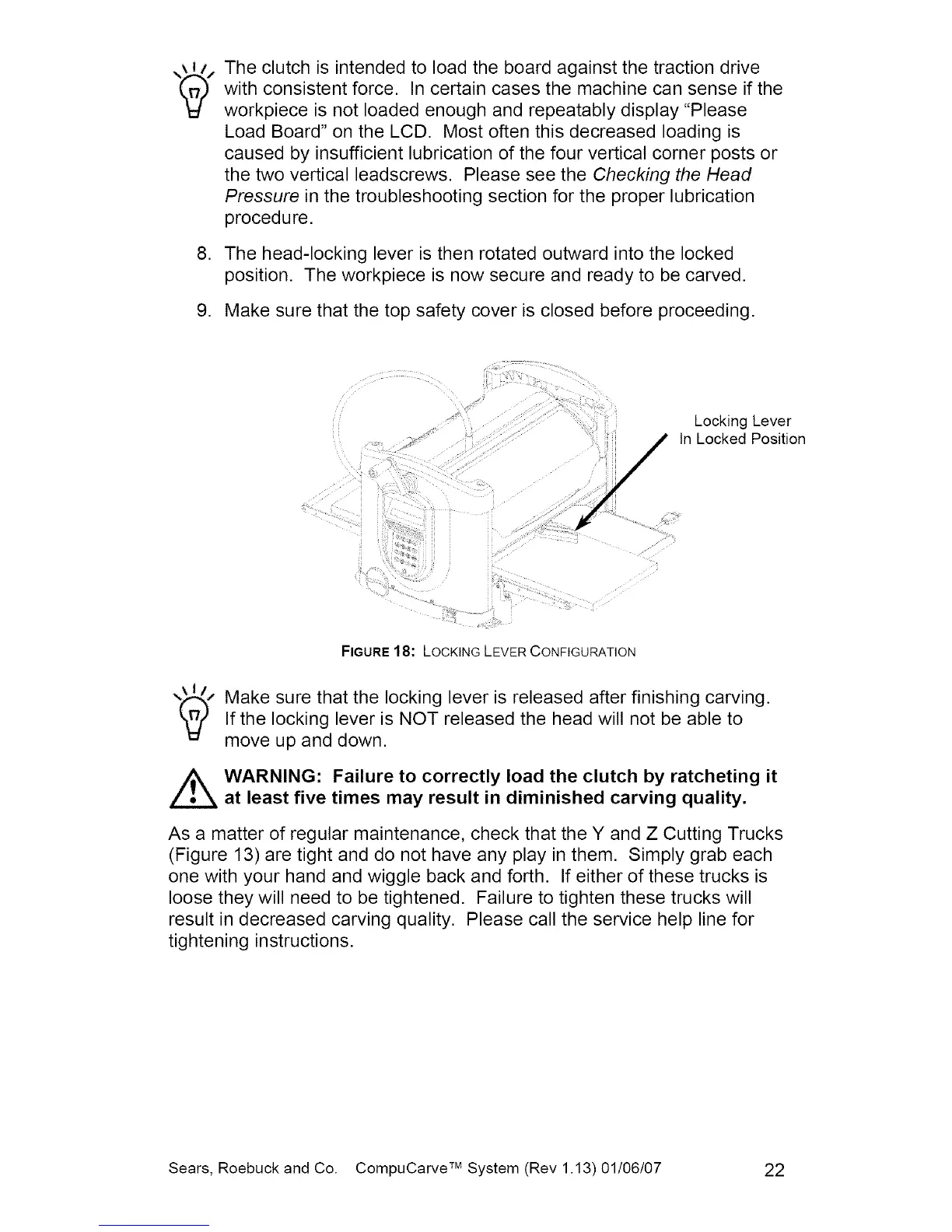

The head-locking lever is then rotated outward into the locked

position. The workpiece is now secure and ready to be carved.

9. Make sure that the top safety cover is closed before proceeding.

i_i !_Z_

Locking Lever

......... In Locked Position

FIGURE18: LOCKING LEVER CONFIGURATION

Make sure that the locking lever is released after finishing carving.

If the locking lever is NOT released the head will not be able to

move up and down.

_ ARNING: Failure to correctly load the clutch by ratcheting it

at least five times may result in diminished carving quality.

As a matter of regular maintenance, check that the Y and Z Cutting Trucks

(Figure 13) are tight and do not have any play in them. Simply grab each

one with your hand and wiggle back and forth. If either of these trucks is

loose they will need to be tightened. Failure to tighten these trucks will

result in decreased carving quality. Please call the service help line for

tightening instructions.

Sears, Roebuck and Co. CompuCarve TM System (Rev 1.13) 01/06/07 22

Loading...

Loading...