Software Operation

Advanced Setting

Solid fill top: Refers to whether to print the top surface of the

model, uncheck will print it with infill method.

Solid fill bottom: Same as above, and so on.

Spiralis print: Refers to the method of spiral printing the outer

wall of the model (single layer), and this feature is very

suitable for print glass vase model.

Enable retraction: When the nozzle is moving over a none-

printed area, withdraw a certain length length filament to

prevent overflow.

Retract speed: The speed of retraction, too fast can lead

motor out of step, too slow increase printing time.

Retract distance: The length of the filament when enable

retraction.

First layer thickness: Height of the first layer of printing,

generally greater than 0.15mm.

First layer flow: When the set of the first layer is too high, it

can be appropriate to increase the extrusion.

Cut off object bottom: This can be used for objects that do

not have a flat bottom.

Continue print: Being "power outages continued" be

substituted.

Travel speed: The speed when moving over a non-printed

area.

First layer speed: Slightly slow speed can enhance adhesion

model on the platform.

Solid layer speed: The speed is a percentage here, which reference to the global print speed, a

combination of different speeds, you can both get a good print quality and a faster print

time.

Spiralise Printing

- 29 -

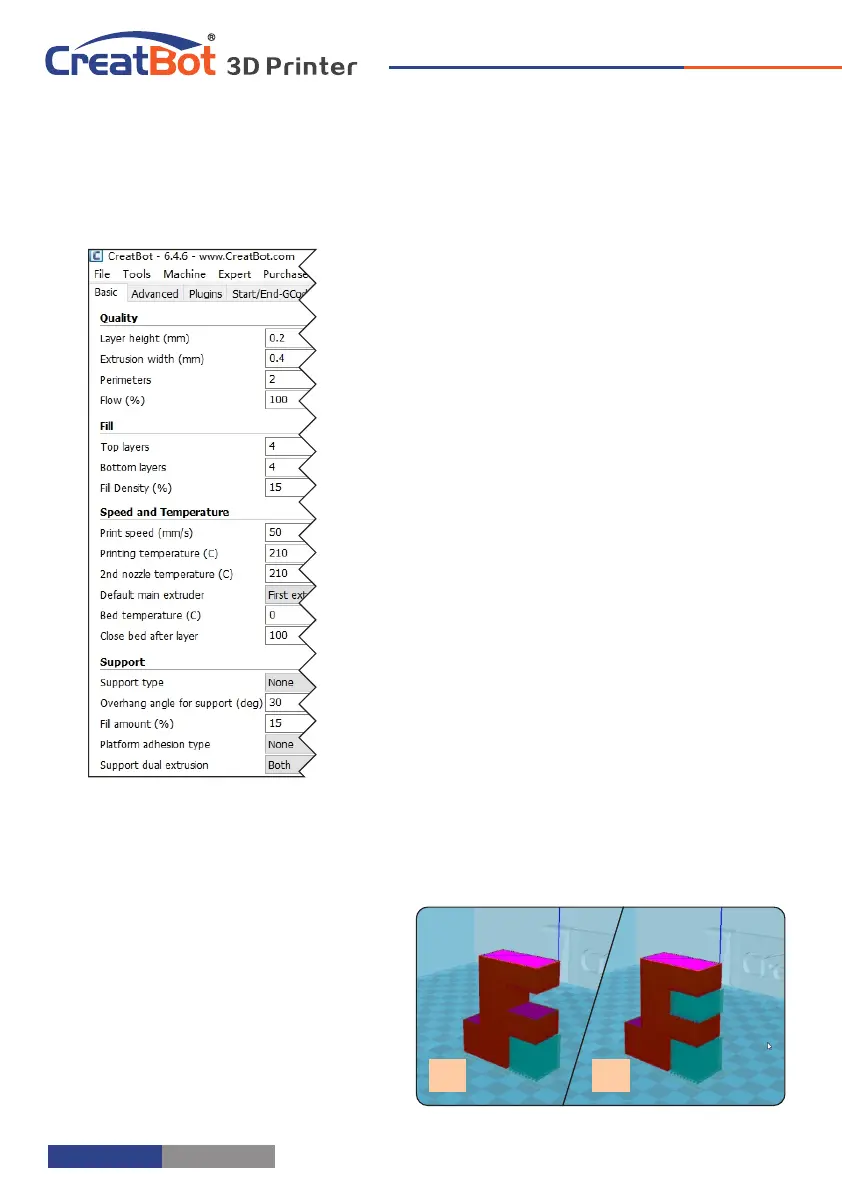

Basic Setting

Software Operation

Layer height: This is the most important setting to determent the

quality of your print, maximum value not exceed 80% of the

nozzle diameter.

Shell thickness: Refers to the total thickness of the inner and

outer walls, the outer wall is only one, the inner wall can be

more, set this value to an integer multiple of the diameter of

the nozzle.

Flow: Refer to the amount of printing material, 100% standard

dosage, the more material the model prints more plump.

top/bottom thickness: Is the thickness of the upper and lower

models, usually a multiple of layer height.

Fill density: Control how density filled the insides of your print

will be, a value around 20% is usually enough, 0% for hollow.

Print speed: Speed at which printing happens. Print speed is

affected by many factors, it is recommended to use low

speed for complex model, high speed will cause the feed

shortage, need improve nozzle temperature to compensate.

Nozzle temperature: Is the melting temperature of filament,

general use 200 ℃ for PLA and 240 ℃ for ABS.

Bed Temperature: General use 45 ℃ for PLA and 70 ℃ for ABS.

Default main head: The default is the first nozzle, can also be set

to other nozzles, this can reduce the times of changing

filament.

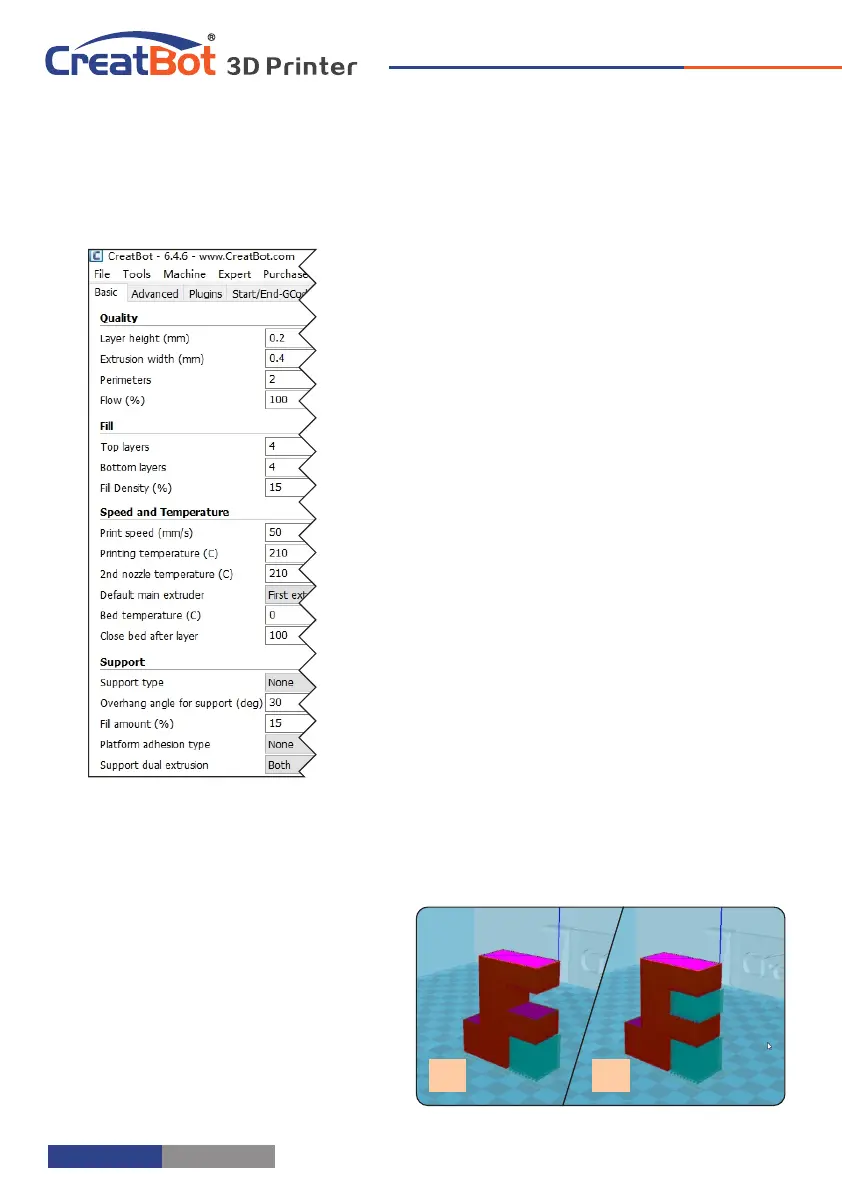

Support type: The touching build plate support type is shown in

figure , everywhere support is shown in figure [A] [B].

Support angle: The larger the angle, the more support generate.

Fill amount: The larger the fill, the more support generate.

Platform adhesion type: The model which is not easy adhesion

on the platform please use Brim, which easy to warped or

ABS filament please use Raft.

Support Type

A B

- 28 -

Loading...

Loading...