4–12 FRONT

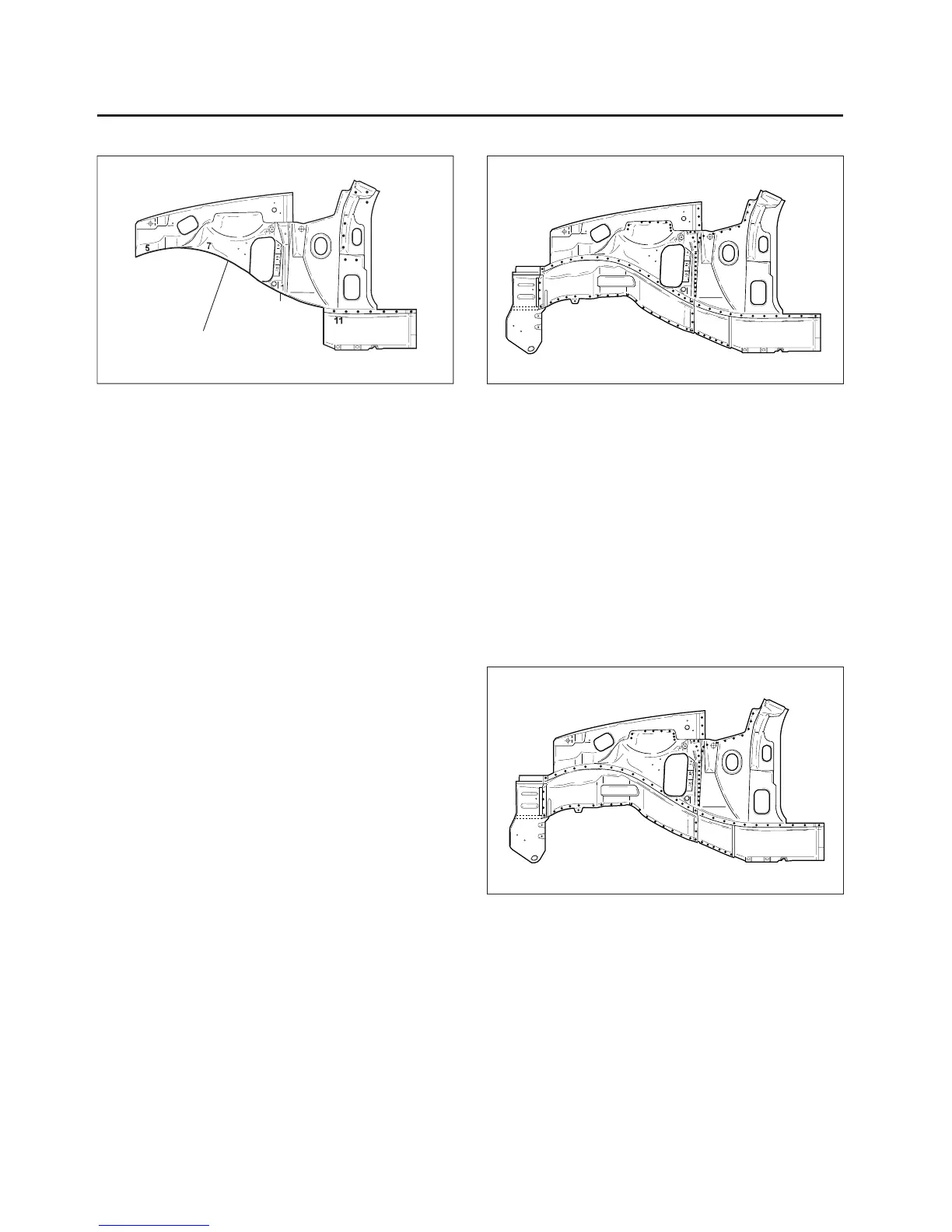

Fig. 18

6. Cut the new front longitudinal to align it with body,

then set the wheelhouse and front panel.

• Cut the new front longitudinal with a hand saw

and it will be butt welded.

• Grind both sides of the welding section of the front

longitudinal and wheelhouse with a disc sander

to remove the paint and expose the steel plate.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

• Tighten the new front longitudinal against remain-

ing parts with the vise grips and pliers.

• Place a jack under the front longitudinal end and

support it, and measure the positions for correct

setting.

• Set and clamp the front panel in place with the

vise grips.

NOTE: Use of jigs is recommended for correct posi-

tions and check that the both front longitudinal and

wheelhouse are parallel.

• Tack weld the clamped section for temporary in-

stallation.

7. Perform the main welding.

• Weld as much as possible with the jig still

mounted.

• Make MIG or gas welds at the butt joints at the

front longitudinal, carefully.

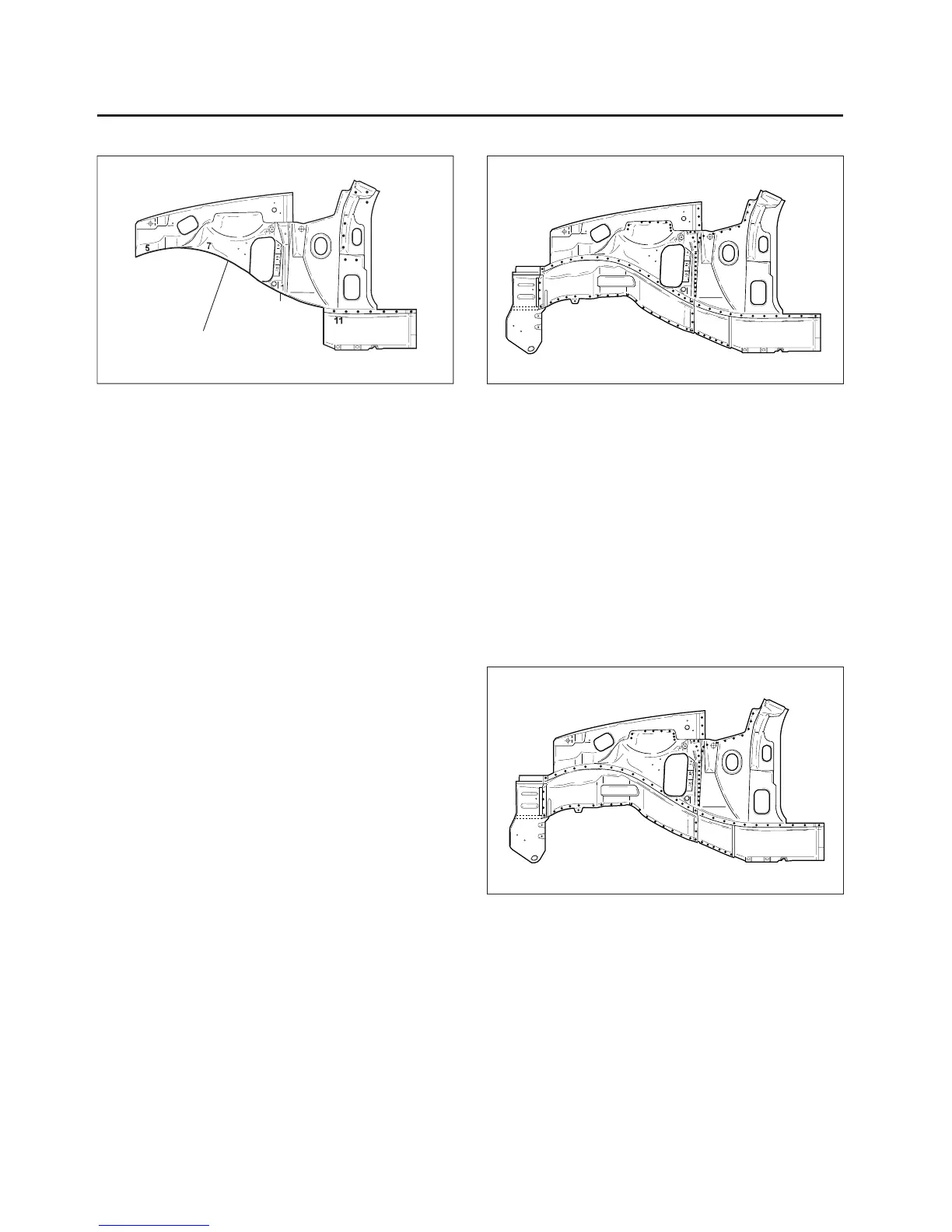

Fig. 19

3

5

12

3

7

5

7

3

3

11

6

1

1

11

2

2

• Spot weld the wheelhouse with the front longitu-

dinal flange areas and front panel.

CAUTION: To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

• Perform a trial welding first, and check the weld-

ing condition.

• Increase the number of spot by 20% for areas to

be spot welded.

Fig. 20

3

5

12

3

7

5

7

3

3

11

6

1

1

11

2

2

• Level the weld beads at the longitudinal butt joints

area with disc sander.

• Make the stiffener(Thickness: 2.8 mm Min., Width:

80 mm) according to the form of longitudinal butt

joint areas and weld the stiffener at the longitudi-

nal butt joint areas with MIG welder.

FRONT WHEELHOUSE

Loading...

Loading...