4–20 FRONT

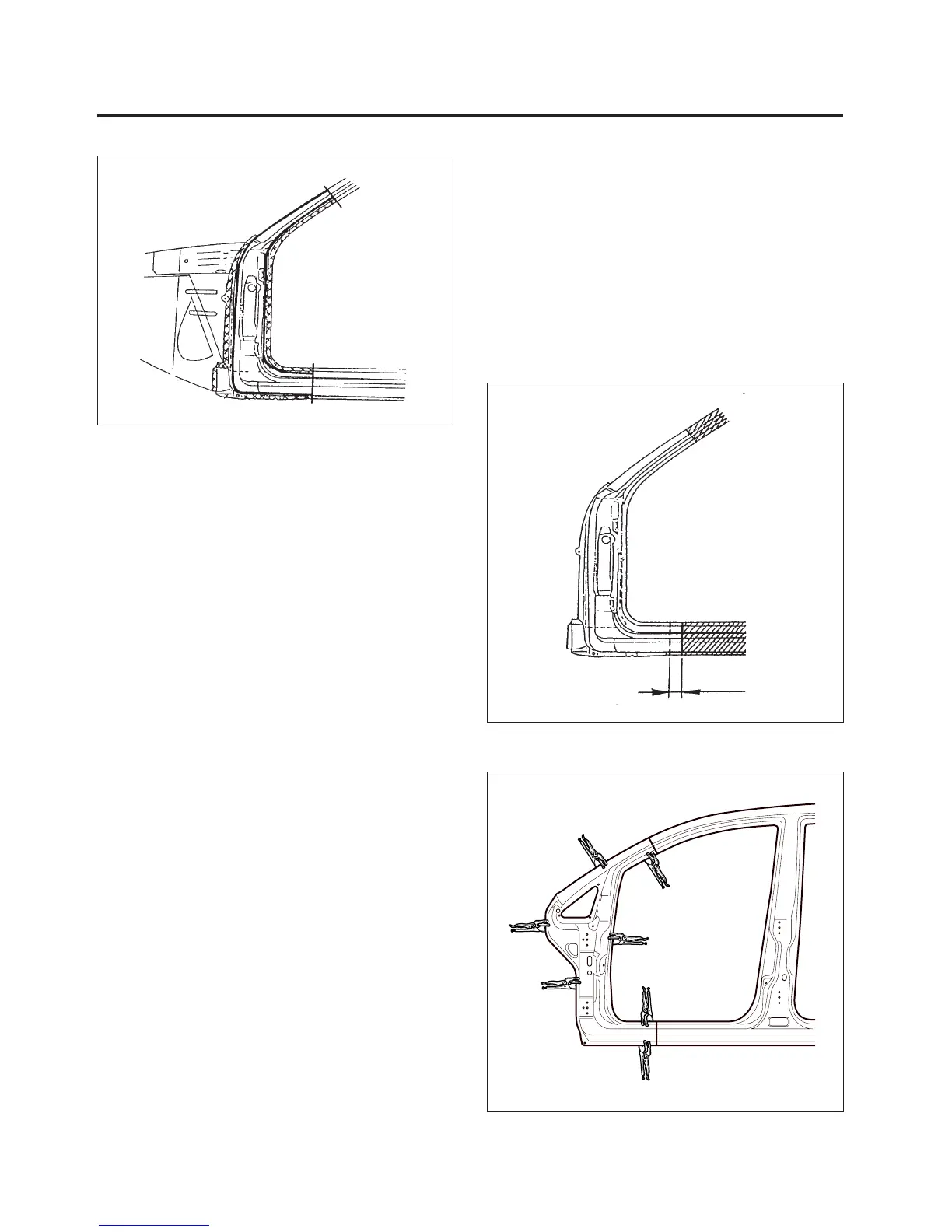

Fig. 29

• Center punch around the spot weld imprints with

the rear wheelhouse, front body pillar inner, rein-

forcement front body pillar inner and floor panel

side.

• Use the special spot cutter to drill holes at the

spot weld nuggets on the front pillar.

NOTE: When drilling holes be careful not to drill down

to the front body pillar inner, reinforcement front body

pillar inner and floor panel side themselves.

• Pry off the remaining flanges from the body with

an air chisel and leaving the welding flanges.

• Level and finish the burrs from the pried off spot

welds with a hammer, dolly and disc sander.

CAUTION: To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

6. Mold damaged related parts.

• Fill any holes drilled by welding.

CAUTION: To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

• Use a hammer and dolly to mold damaged areas

of the remaining inner panel and even out the

welding flanges.

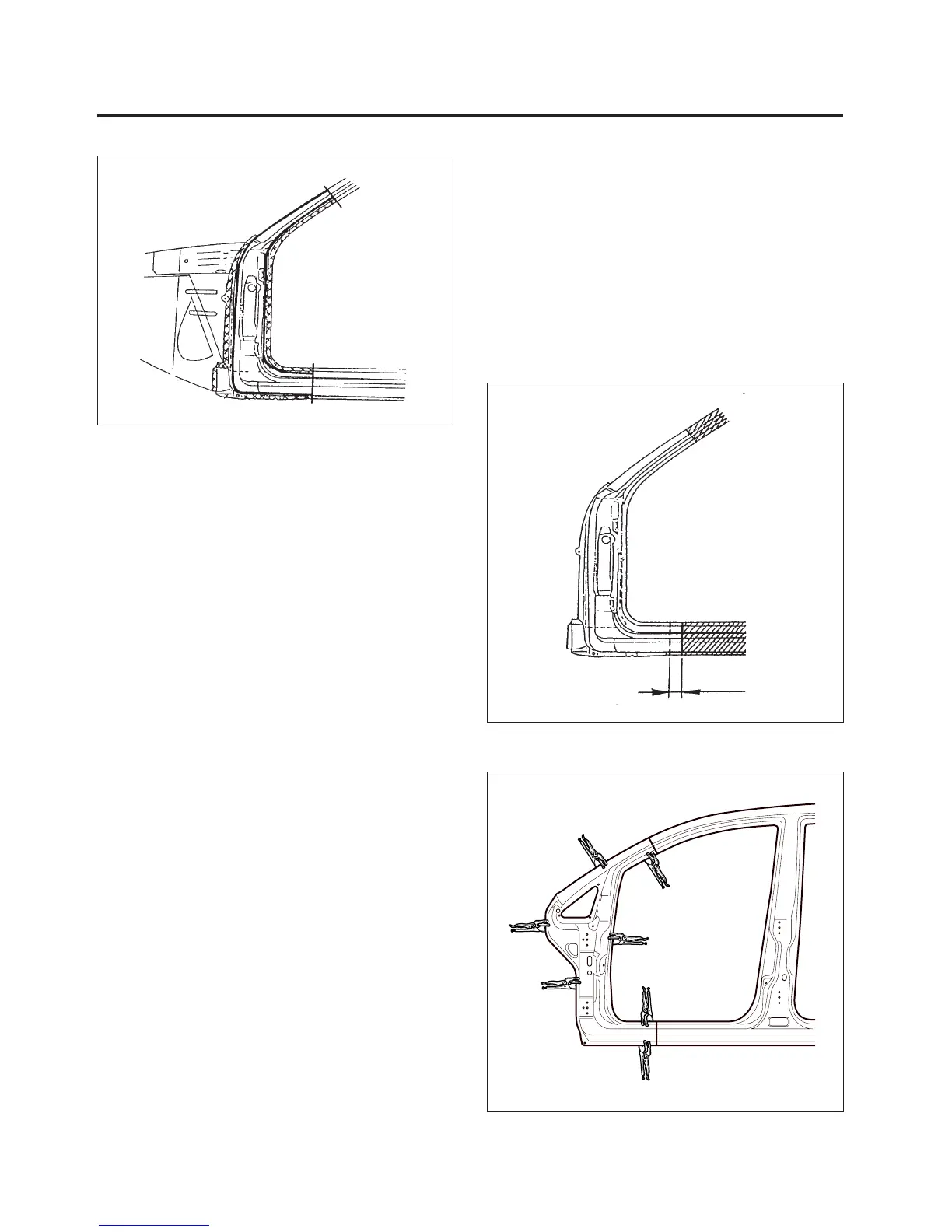

7. Set the new front pillar.

• Align the new part with the top section, then cut

it with a hand saw.

• Cut the floor panel side joint area so it will over-

lap by 30mm(1.18in.) in the floor panel side with

a hand saw.

• Grind both sides of the welding section with a disk

sander to remove the paint and expose the steel

plate.

• Clamp the new panel in place with the vise grips.

• Tack weld the clamped section for temporary in-

stallation.

Fig. 30

Fig. 31

30mm(1.18in.)

Loading...

Loading...