FRONT 4–21

CAUTION: To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves and

safety shoes.

• Remove the vise grips and temporarily install the

fender and doors, then check the clearances, level

differences and outer appearance.

8. Perform the main welding.

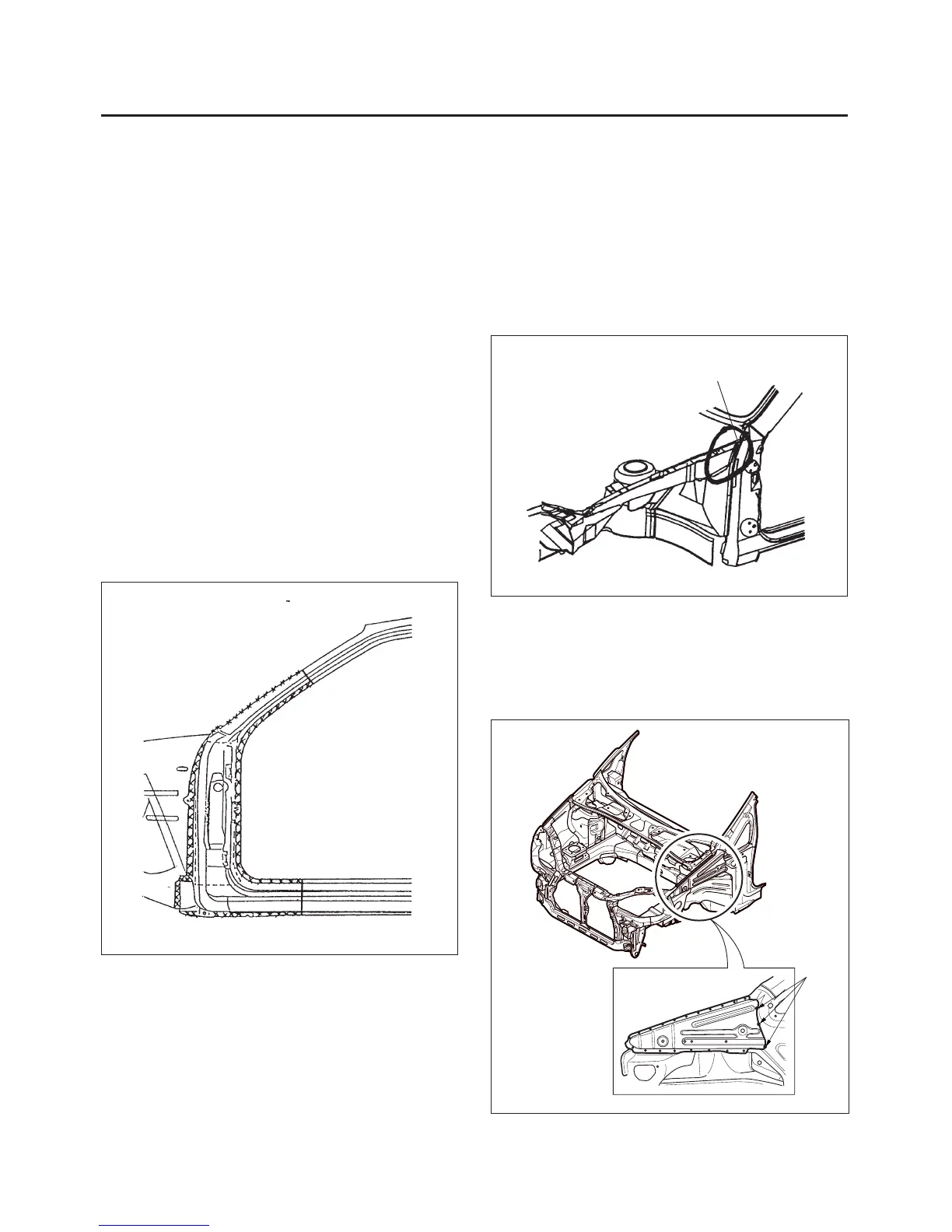

• Weld the frame door opening area and pillar at

the butt joints with a gas or MIG welder.

• Spot weld the flanges of the front pillar as shown.

CAUTION: To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves and

safety shoes.

• Perform a trial welding first, and check the weld-

ing condition.

• Increase the number of spot by 20% for areas to

be spot welded.

Fig. 32

9. Finish the welding areas.

• Level the gas or MIG welded areas with a disc sander,

then even out high areas with a hammer being care-

ful not to deform them.

CAUTION: To prevent eye injury, wear goggles or

safety glasses whenever sanding cutting or grinding.

• Use a hammer and dolly to even out the spot welded

flanges for a close fit with the surface of the inner

panel.

• Fill in deformations and level differences of the welded

areas with solder or putty, then finish.

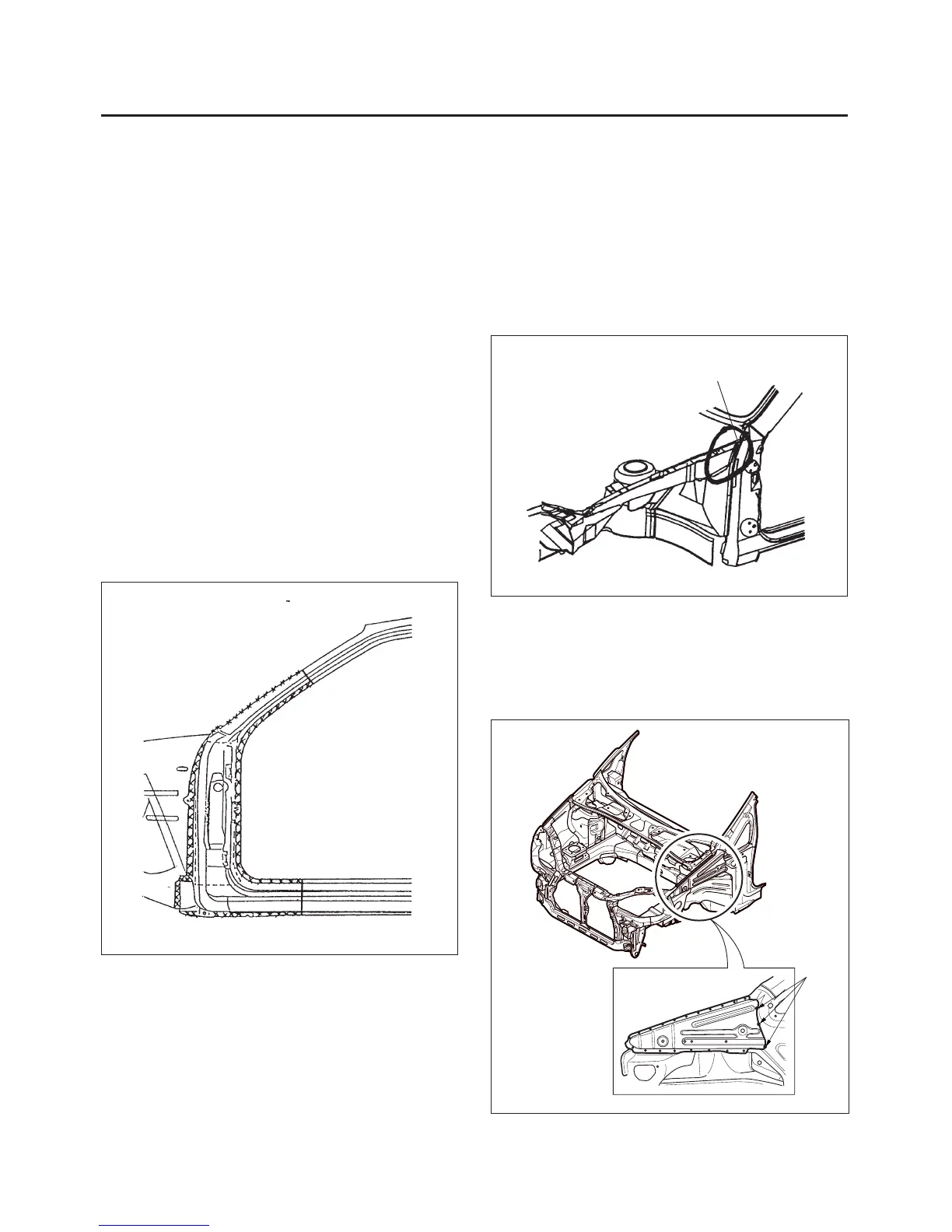

10.Apply the sealer tape.

• Apply the sealer tape to the hinge and brace

wheelhouse matching area as shown.

Fig. 33

SEALER TAPE

Fig. 34

11.Weld the brace wheelhouse.

• Spot weld the brace wheelhouse as shown.

• Make MIG or gas welds at the door hinge areas.

Loading...

Loading...