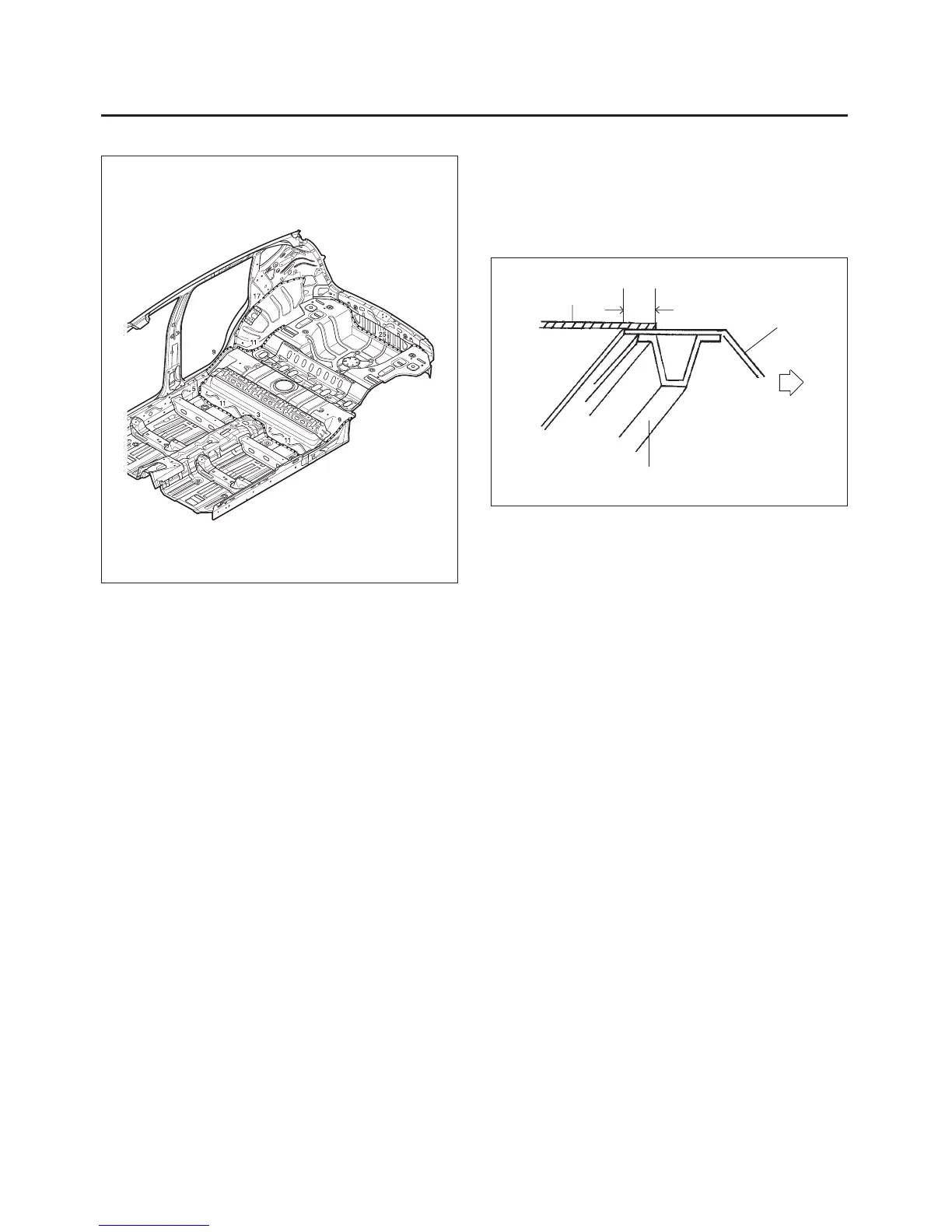

ROOF, BACK PANEL AND REAR FLOOR PANEL 5–13

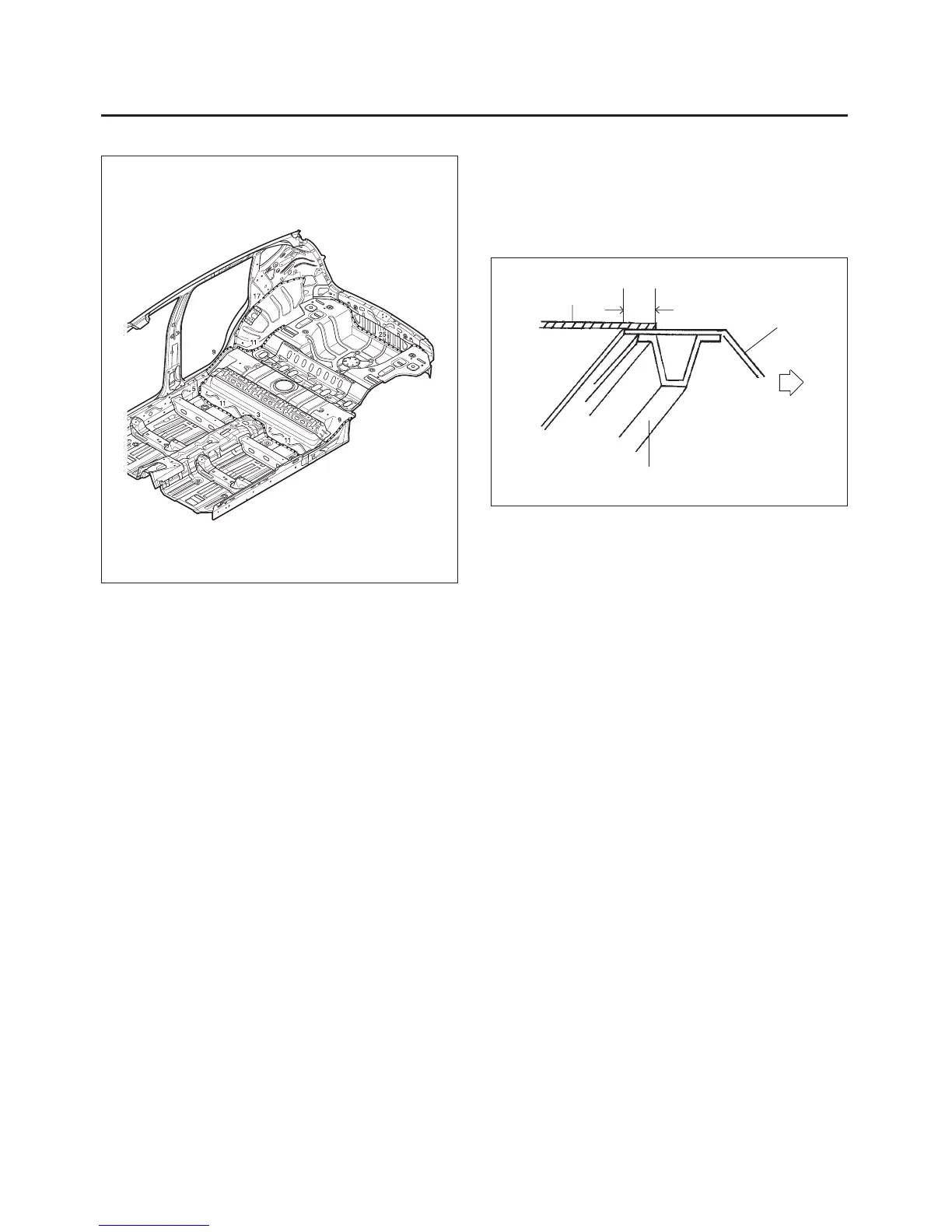

7. Cut the new rear floor to align it with the body, then

set the new rear floor and extension rear floor.

• Cut the new part so it overlaps the cross member

rear seat by approximately 40mm.

Fig. 17

5. Peel off the undercoat and sealer.

• Heat the undercoat and sealer at the welding

areas with a gas torch and peel off the undercoat

and sealer with a steel spatula.

6. Mold damaged related parts.

• Use a hammer and dolly to mold damaged areas

of the rear longitudinal and extension rear longi-

tudinal.

• Even out the welding flanges with a hammer and

dolly.

• Fill any holes drilled by welding.

CAUTION: To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

• Level and finish the burrs from the pried off spot

welds with disc sander.

• Sand off the paint and undercoat from both sides

of the flange to be welded.

Fig. 18

FORWARD

REAR FLOOR

NEW REAR FLOOR

CROSS MEMBER REAR SEAT

40mm

• Grind both sides of the welding section of the rear

floor and extension rear floor with a disk sander

to remove the paint and expose the steel plate.

CAUTION: To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

• Set and clamp the new panel in place with the vise

grips.

NOTE: Use of jigs is recommended for correct posi-

tions and check that the both rear logitudinal is par-

allel.

• Tack weld the clamped section for temporary in-

stallation.

CAUTION: To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

• Remove the vise grips and temporarily install the

rear panel, then check the alignment, level dif-

ferences and outer appearance.

Loading...

Loading...