- 19 -

Mountthelinedisconnectswitchwithfuse

oreachno-fusebreakeroneachweldingmachine.

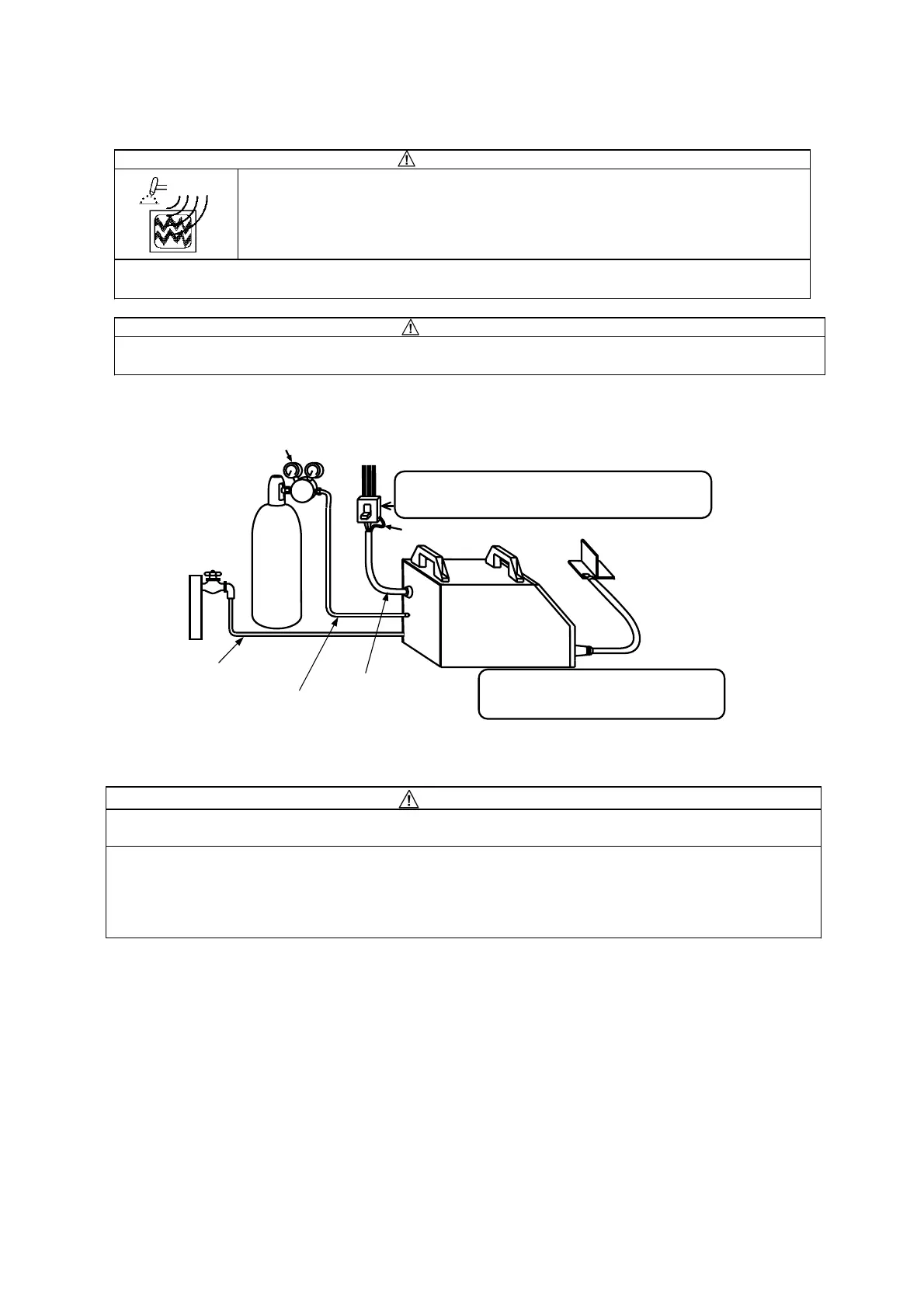

ԘGas regulator

ԙGashose

Basemetalorjig

ԜInputcables

andGroundingwire

ԛGREEN/YELLOWcablefor groundingcable

Surelyconnecttheinputandgrounding

Cables 4mm

2

tothecircuitbreaker.

Ground a work piece if a

local law requires.

ԚWater-cooling hose

8.

CONNECTION PROCEDURE AND GROUND FOR SAFETY USE (continued)

CAUTION

To prevent electromagnetic troubles, read the following.

Also, if electromagnetic troubles occur, check the following again.

٨

Add a noise filter to the input cables.

٨

Do not ground the welding power source commonly with other machines.

CAUTION

٨Be sure to install a switch with fuse or a circuit breaker (for motor) to the input sides of each

welding machine.

The following figure shows the cable connections. When using the air-cooled torch, the water supply

hose is not necessary. For STICK welding, the water/gas hoses are not necessary.

CAUTION

Be sure to ground the case of the welding power source.

Use a grounding cable 4mm

2

or more in thickness.

٨If the welding power source which is not grounded is used, voltage will be generated in the

case through the capacitor between the welding power source input circuit and the case or

stray capacity (electrostatic capacity naturally generated between the input circuit and the

metal enclosure). If you touch the case or the base metal, you may suffer from electric shock.

Be sure to ground the case of the welding power source or jig.

HF

Loading...

Loading...