- 81 -

14. SPECIFICATIONS (continued)

٨Initial Values and Setting Range of Parameters

Initial value Setting range

Pre flow time 0.3 sec. 0 – 20 sec.

Up slope time 1 sec. 0 – 10 sec.

Welding current for stick welding 10 A

10 – 250 A

䊶 Initial current

䊶 Welding current

䊶 Pulse current

䊶 Crater current

DC TIG

10 A

4 – 300 A

AC TIG

AC-DC 䌔䌉䌇

STANDARD

HARD

10 - 300 A

SOFT 10 – 200 A

Pulse frequency 2 Hz 0.1 – 500 Hz

Down slope time 1 sec. 0 – 10 sec.

Post flow time 7 sec. 0 – 30 sec.

Arc spot time 3 sec. 0.1 – 10 sec.

AC frequency 70 Hz 50 – 200 Hz

AC balance 0 -20 – 20

AC-DC change frequency 1 Hz 0.1 – 50 Hz

Condition number 1 1 – 100

٨Function

Initial value Setting range

Crater OFF OFF / ON / REPEAT / ARC SPOT

Welding method AC TIG

AC TIG / AC-DC TIG

DC TIG / DC STICK welding

AC wave form STANDARD STANDARD / SOFT / HARD

Initial current OFF ON / OFF

Pulse OFF ON / OFF

Lift start OFF Lift start / High frequency start

Slope OFF ON / OFF

Torch AIR Water / Air

٨Internal function <Refer to 10.1.17 Internal Functions for detail.>

What can and cannot be stored in memory by each welding conditions memory number are

discriminated by “٤” and “” given in the table below.

Memory Initial value Setting range

F1

Start current

ON ON (HIGH) / OFF (LOW)

䌆2

Change in sequence at arc spot time

OFF ON (VALID) / OFF (INVALID)

F3

Termination of repetition

OFF ON (VALID) / OFF (INVALID)

F4

Automatic/Stick

OFF ON (AUTOMATIC) / OFF (STICK)

F5

External command 12 V MAX

OFF ON (VALID) / OFF (INVALID)

F6

External command 10䌖䌍䌁䌘

OFF ON (VALID) / OFF (INVALID)

F7

Pulse peak ratio

٤

50 % 5 – 95 %

F8

Voltage reducing function

OFF ON (VALID) / OFF (INVALID)

F9

Result display holding time

20 sec. 0 – 60 sec.

F10

AC ratio

٤

70 % 10 – 90 %

F11

Change of operation sound

ON ON (VALID) / OFF (INVALID)

F12

Change of external output terminal 1

1

1:Power preparation

2:Pulse synchronized output

3:EN synchronized output

4:AC synchronized output

F13

Change of external output terminal 2

2

F14

Change of pulse synchronized input

signal

OFF ON (VALID) / OFF (INVALID)

F15

Indication change of AC balance

indication

OFF

ON (EP ratio indication) / OFF

(±indication)

F16

Soft pulse

OFF ON (soft pulse) / OFF (standard)

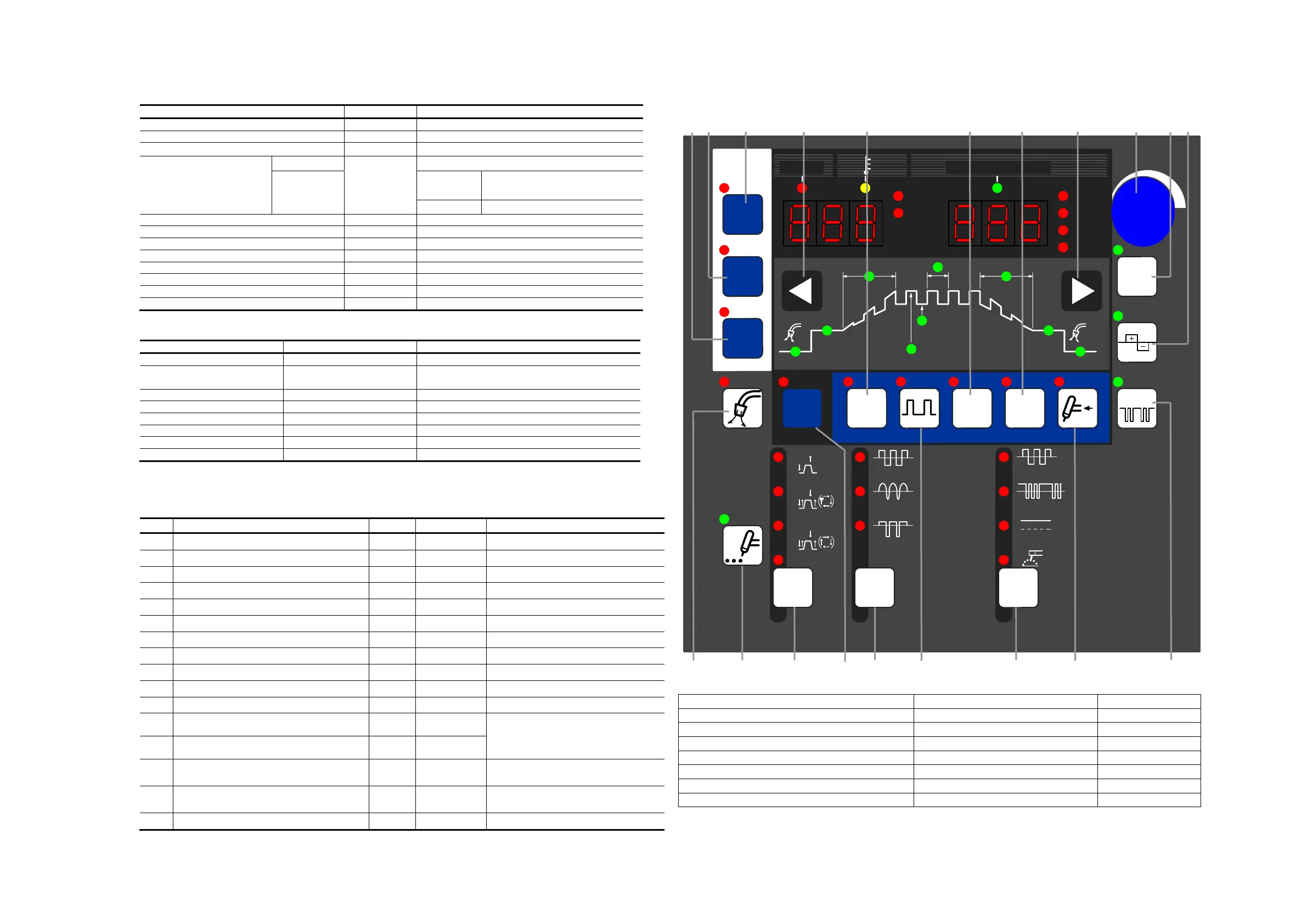

٨In reading the “Operation” paragraph described in “10.1 Basic Setup” and in the subsequent paragraphs,

consult this page to check the key location or the like.

[19][18] [17] [3] [11] [13]

[14]

[3] [4] [6] [7]

[16] [9] [5] [10] [2] [12] [1] [15] [8]

[1] WELDING METHOD change-over key [9] ARC SPOT TIME setting key [17] LOAD key

[2] AC WAVE change-over key [10] Function selection key [18] SAVE key

[3] Parameter selection key [11] INITIAL CURR. selection key [19] ENTER key

[4] Parameter adjusting knob [12] PULSE selection key

[5] CRATER FILL. key [13] LIFT START key

[6] AC FREQ. key [14] SLOPE selection key

[7] AC BALANCE key [15] TORCH change-over key

[8] AC-DC change-over frequency setup key [16] GAS CHECK key

* Further, F17 to F20 have the functions as well. For details, see 10.1.17 “Internal Functions”.

㧲

t

f

CRATER

FILL.

SPOT TIME

GAS

CHECK

OFF

ON

REPEAT

SPOT

WELDI NG

METHOD

ON ON ON ON WATER

TORCH

SLOPE

INIT IAL

CURR.

PULSE

LIFT

START

LOAD

SAVE

ENTER

ASec

Hz

%

JOB

MEMORY

JOB NO.

AC- TIG

DC- STI CK

AC- DC TI G

DC- TIG

PULSE CURR.

㧔

BASE CURR.

㧕

PULSE FREQ.

UP SLOPE

DOWN SLOPE

I NITI AL CURR. CRATER- FILL.

CURR.

WELDING CURR.

㧭㧯

WAVE

㧭㧯

FREQ.

AC- DC

FREQ.

STANDARD

SOFT

HARD

DC NO- LOAD VOLTAGEWARNI NG

T1 T2

AC BALANCE

Loading...

Loading...