- 23 -

9. WELDING PREPARATION (continued)

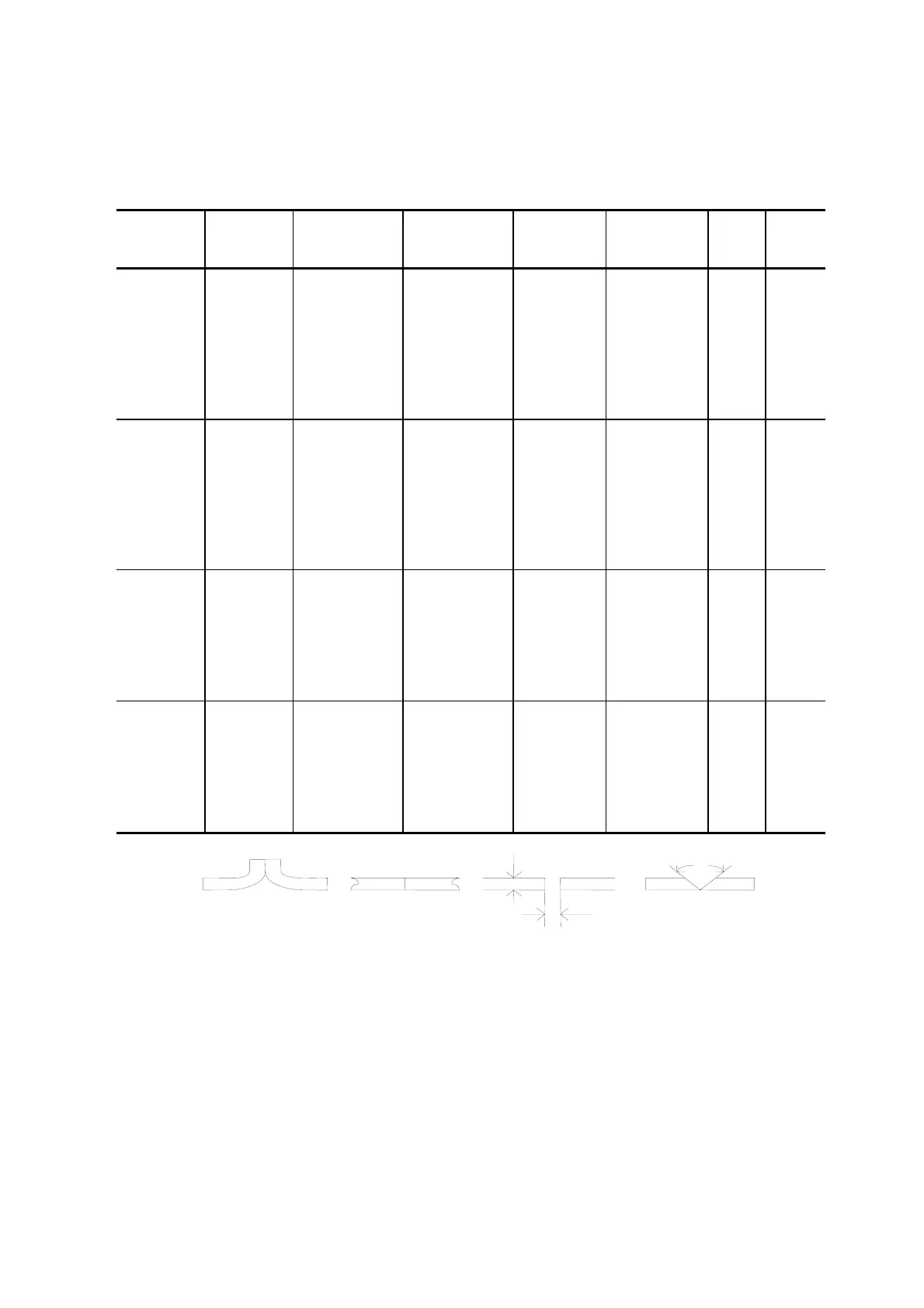

9.4 TIG Welding Condition㧔for reference㧕

(1) TIG Welding Condition㧔PULSE “OFF”㧕

Material

Plate

Thickness

(mm)

Electrode Dia.

(mm)

Filler Wire Dia.

(mm)

Current

(A)

Argon Gas

Flow Rate

(ℓ/min)

No. of

Layer

Bevel

Shape

Stainless

Steel

(DC,

Electrode

Negative)

0.6 1, 1.6 0 - 1.6 20 - 40 4 1 (a), (b)

1.0 1, 1.6 0 - 1.6 30 - 60 4 1 (a), (b)

1.6 1.6, 2.4 0 - 1.6 60 - 90 4 1 (b)

2.4 1.6, 2.4 1.6 - 2.4 80 - 120 4 1 (b)

3.2 2.4, 3.2 2.4 - 3.2 110 - 150 5 1 (b)

4.0 2.4, 3.2 2.4 - 3.2 130 - 180 5 1 (d), (c)

4.8 2.4, 3.2, 4 2.4 - 4.0 150 - 220 5 1 (d), (c)

6.4 3.2, 4, 4.8 3.2 - 4.8 180 - 250 5 1 - 2 (a), (c)

Deoxidized

Copper

(DC,

Electrode

Negative)

0.6 1, 1.6 0 - 1.6 50 - 70 3 - 4 1 (a), (b)

1.0 1.6 0 - 1.6 60 - 90 3 - 4 1 (a), (b)

1.6 2.4 1.6 - 2.4 80 - 120 3 - 4 1 (b)

2.4 2.4, 3.2 2.4 - 3.2 110 - 150 4 1 (b)

3.2 3.2, 4 3.2 - 4.8 140 - 200 4 - 5 1 (c)

4.0 3.2, 4, 4.8 4.0 - 4.8 180 - 250 4 - 5 1 (d), (c)

4.8 4, 4.8 4.8 - 6.4 250 - 300 5 - 6 1 (d), (c)

6.4 4, 4.8, 6.4 4.8 - 6.4 300 - 400 5 - 6 1 - 2 (d), (c)

Aluminum

(AC)

1.0 1.6 0 - 1.6 50 - 60 5

6 1 (a), (b)

1.6 1.6, 2.4 0 - 1.6 60 - 90 5

6 1 (a), (b)

2.4 1.6, 2.4 1.6 - 2.4 80 - 110 6 - 7 1 (b)

3.2 2.4, 3.2 2.4

4.0 100 - 140 6 - 7 1

(b)

4.0 3.2, 4.0 3.2 - 4.8 140 - 180 7 - 8 1

(b)

4.8 3.2, 4.0, 4.8 4.0 - 6.4 170 - 220 7 - 8 1

(b)

6.4 4.0, 4.8 4.0 - 6.4 200 - 270 8

12 1 - 2 (d), (c)

Magnesium

(AC)

1.0 1.6 0 - 1.6 30 - 40 3

4 1 (a)

1.6 1.6, 2.4 1.6 - 2.4 40 - 70 4

5 1 (b)

2.4 1.6, 2.4 1.6 - 2.4 60 - 90 4

5 1 (b)

3.2 1.6, 2.4 2.4

3.2 75 - 110 5 - 6 1

(b)

4.0 2.4, 3.2 3.2 - 4.0 90 - 120 5

6 1

(d), (c)

4.8 3.2, 4.0 3.2 - 4.8 110 - 150 5 - 6 1

(d), (c)

6.4 3.2, 4.0 4.0

4.8 130 - 170 6 - 7 1 - 2 (d), (c)

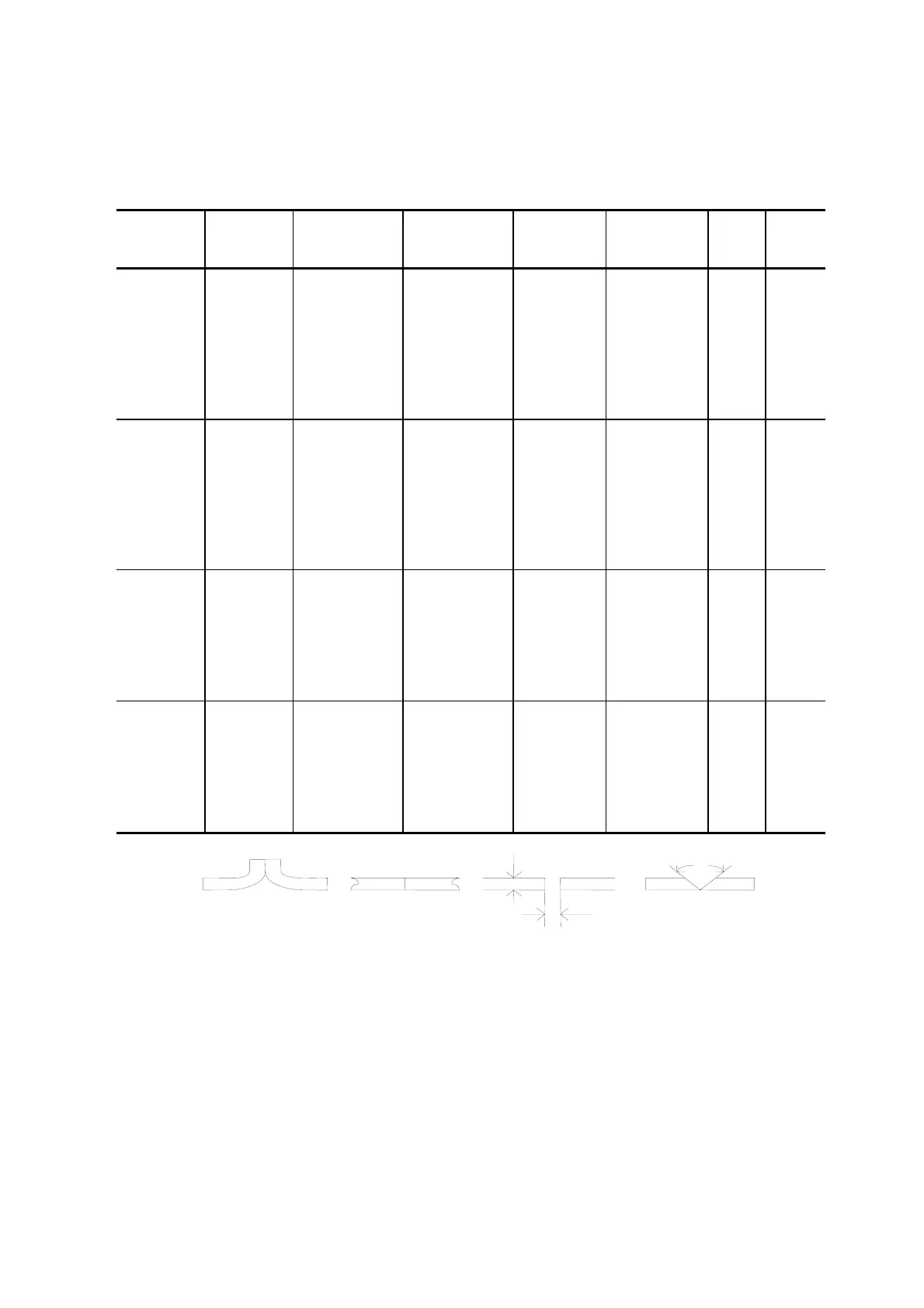

C ҇ t/3

(a) (b)

(c)

(d)

90q

t

Loading...

Loading...