IOM 1242-2 • PATHFINDER

®

MODEL AWV CHILLERS 30 www.DaikinApplied.com

InsTallaTIon and applICaTIon ConsIderaTIons - remoTe evaporaTors

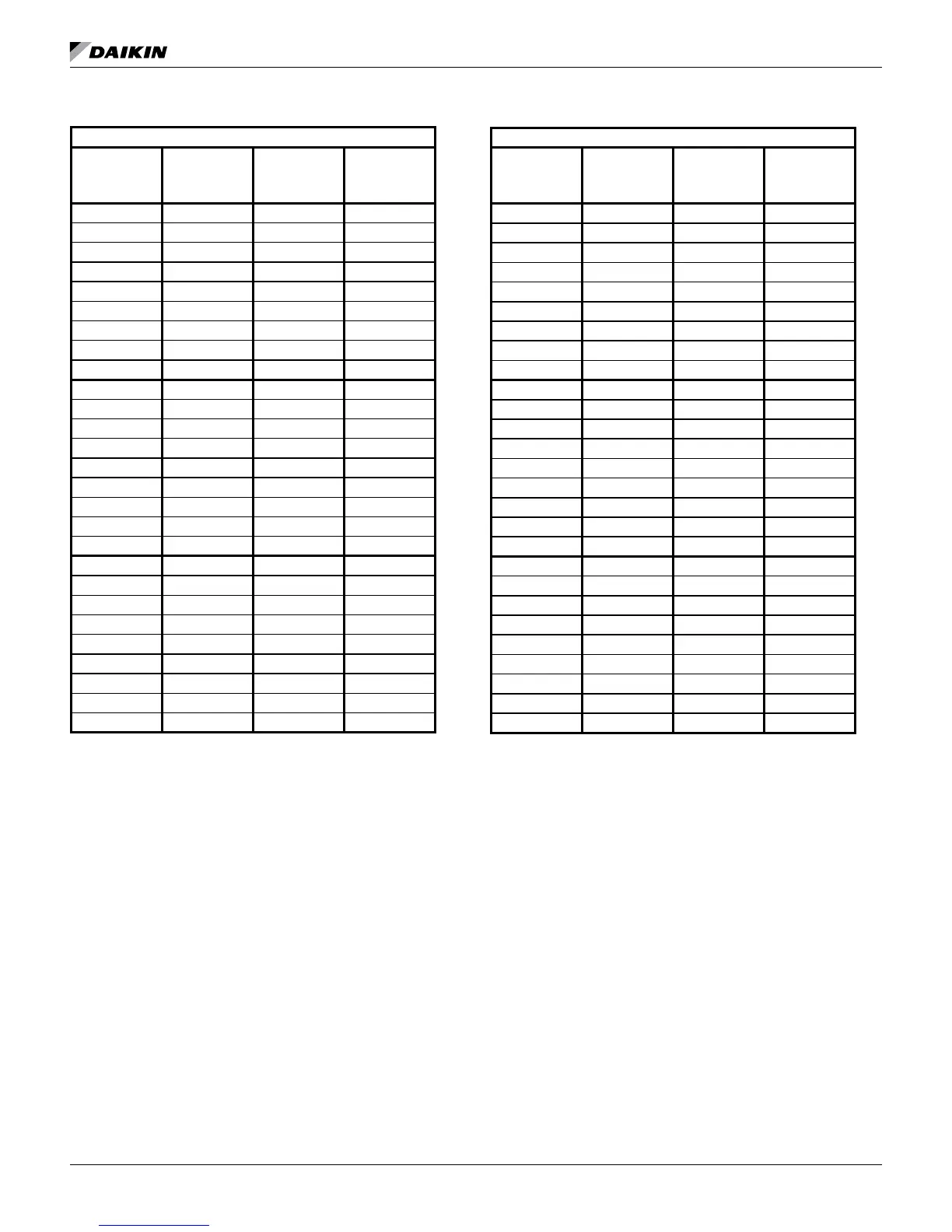

Table 7: Sizing Guidelines for Horizontal or Downow Suction Lines and Liquid Lines

NOTE: Target suction temperature loss less than 2.5°F.

Minimum suction line gas velocity target 1000 FPM

on horizontal and downow piping installations where

the evaporator is at or below the chiller elevation.

Maximum allowable suction line temperature loss

target 5°F; some selections are greater than 5°F

due to minimum velocity requirements at minimum

compressor speed.

Recommended Horizontal or Downow Sucon Line Size

Nominal

Circuit

Capacity

Esmated Line

TEL () Line Material

Sucon Line

Size (Inches)

65 250 Copper 4 1/8

90 250 Copper 4 1/8

115 250 Copper 4 1/8

140 250 Copper 5 1/8

165 250 Copper 5 1/8

190 250 Copper 6 1/8

215 250 Copper 6 1/8

240 250 Copper 6 1/8

265 250 Copper 6 1/8

65 275 Copper 4 1/8

90 275 Copper 4 1/8

115 275 Copper 4 1/8

140 275 Copper 5 1/8

165 275 Copper 5 1/8

190 275 Copper 6 1/8

215 275 Copper 6 1/8

240 275 Copper 6 1/8

265 275 Copper 6 1/8

65 300 Copper 4 1/8

90 300 Copper 4 1/8

115 300 Copper 4 1/8

140 300 Copper 5 1/8

165 300 Copper 5 1/8

190 300 Copper 6 1/8

215 300 Copper 6 1/8

240 300 Copper 6 1/8

265 300 Copper 6 1/8

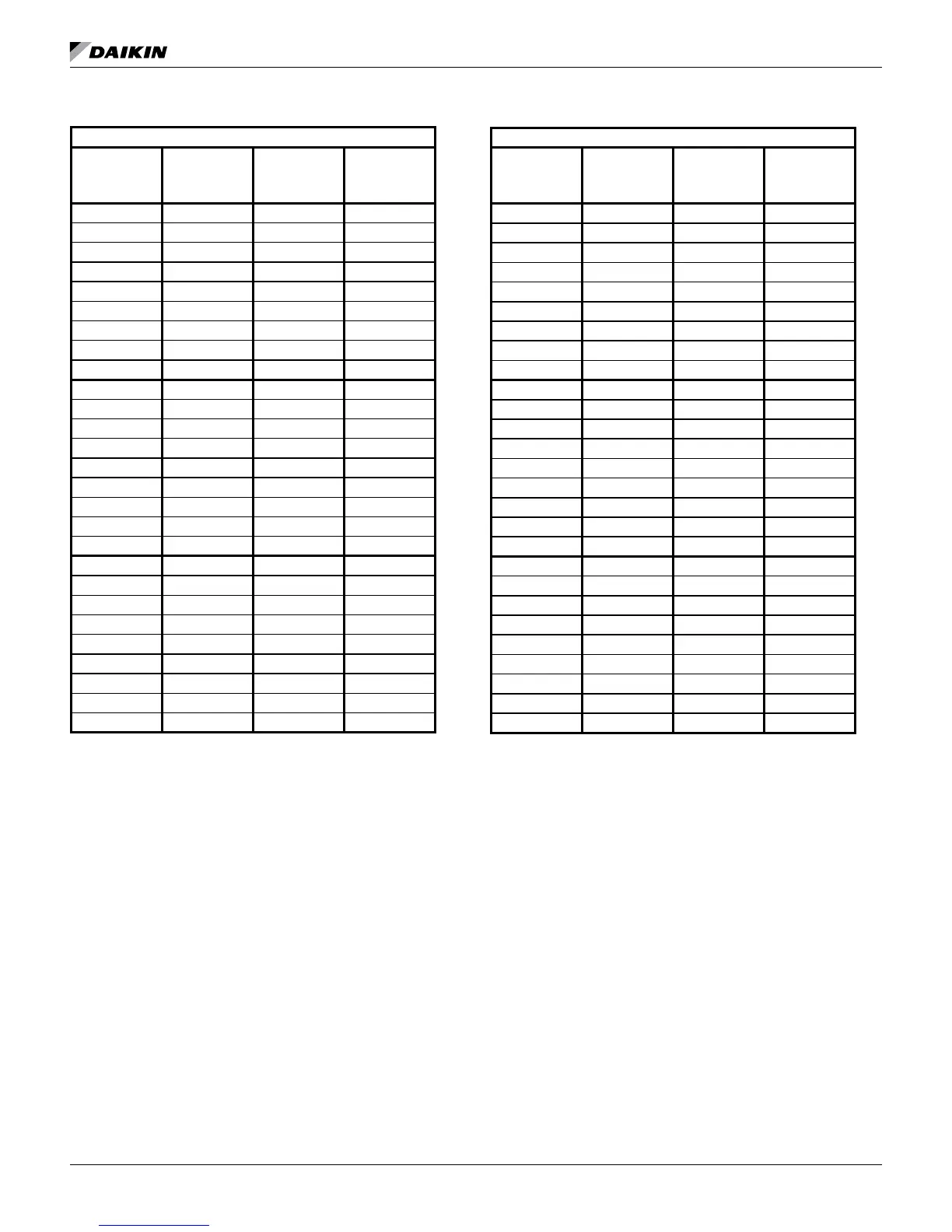

Recommended Liquid Line Sizes

Nominal

Circuit

Capacity

Esmated Line

TEL () Line Material

Liquid Line Size

(Inches)

65 250 Copper 2 1/8

90 250 Copper 2 1/8

115 250 Copper 2 1/8

140 250 Copper 2 5/8

165 250 Copper 2 5/8

190 250 Copper 2 5/8

215 250 Copper 2 5/8

240 250 Copper 3 1/8

265 250 Copper 3 1/8

65 275 Copper 2 1/8

90 275 Copper 2 1/8

115 275 Copper 2 1/8

140 275 Copper 2 5/8

165 275 Copper 2 5/8

190 275 Copper 2 5/8

215 275 Copper 3 1/8

240 275 Copper 3 1/8

265 275 Copper 3 1/8

65 300 Copper 2 1/8

90 300 Copper 2 1/8

115 300 Copper 2 1/8

140 300 Copper 2 5/8

165 300 Copper 2 5/8

190 300 Copper 2 5/8

215 300 Copper 3 1/8

240 300 Copper 3 1/8

265 300 Copper 3 1/8

Loading...

Loading...