CIrCuIT funCTIons

www.DaikinApplied.com 61 IOM 1242-2 • PATHFINDER

®

MODEL AWV CHILLERS

When a capacity increase occurs, a time delay starts; and

when a capacity decrease occurs, a separate time delay starts.

While either of these delays is active, no normal capacity

changes will occur. The load and unload delay times are

calculated values.

Circuit State = Pumpdown - Speed command will drop 2 Hz

every second until reaching the minimum for the conguration.

Manual Speed Control

The speed of the compressor may be controlled manually.

Manual speed control is enabled via a set point with choices

of Auto or Manual. Another set point allows setting the

compressor speed. However, the resulting compressor speed

is still limited to the range from the minimum speed based on

conguration up to the Compressor Maximum Speed set point.

The compressor speed will be stepped up or down until it is

equal to the speed that corresponds to the manual speed set

point. Changes to the speed will be made as fast as allowed by

the calculated load and unload delays. Speed control may be

set to Manual only when circuit state is Start or Run.

Capacity control shall revert back to automatic control if either:

• the circuit state changes from Start or Run to another

state

• capacity control has been set to Manual for four hours

Load and Unload Delay

LWT Error determines the delays for load and unload

commands.

Table 48: Load and Unload Delay Conditions

LWT Error Delay

LWT Error > Startup Delta

T set point

Load command delay is 5

seconds

0.1°C ≤ LWT Error ≤

Startup Delta T set point

Load command delay will vary

from 5 seconds to 10 seconds

– (Stage Down Delta T

set point) ≤ LWT Error ≤

-0.1°C

Unload command delay will

vary from 3 seconds to 6

seconds

LWT Error < -(Stage Down

Delta T set point)

Unload command delay is 3

seconds

VR Solenoid Valve Control

There are three solenoid valves for changing volume ratio of

the compressor:

• 50 VR solenoid valve

• 75 VR solenoid valve

• 100 VR solenoid valve

The compressor should start with all three solenoid valves off.

After compressor has been running for at least 20 seconds, the

control logic will “stage” the solenoid valves. Table 49 shows

which VR solenoid valves are on at each stage as well as

stage up and stage down conditions. These staging conditions

must be active for 30 seconds to trigger each stage up or

down.

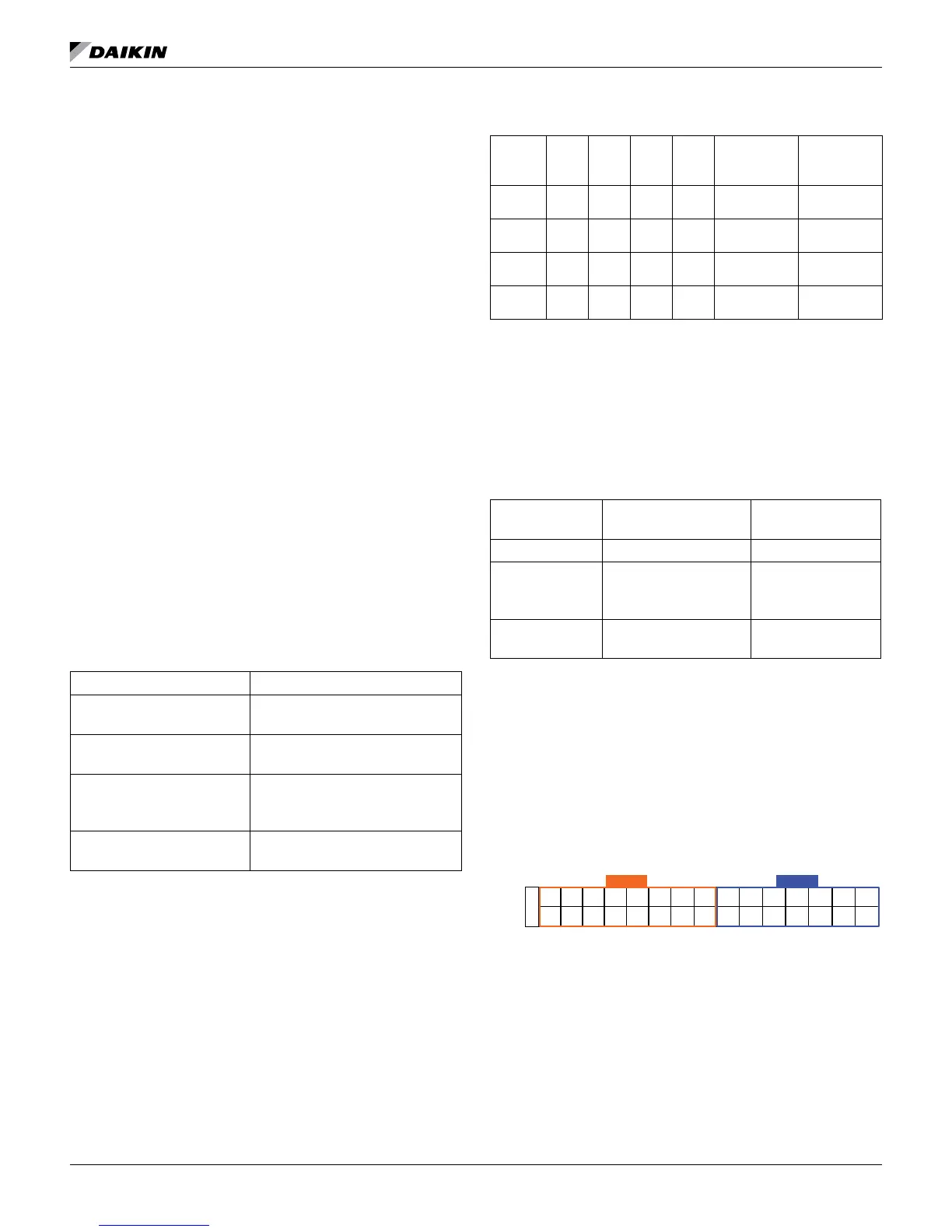

Table 49: VR Solenoid Valve Control Stages

Stage VR

50

VR

SV

75

VR

SV

100

VR

SV

Stage Up

Condition

Stage Down

Condition

0 1.6 Off Off Off

Pressure

Ratio > 2.10

n/a

1 1.8 On Off Off

Pressure

Ratio > 2.85

Pressure

Ratio < 1.90

2 2.4 Off On Off

Pressure

Ratio > 3.85

Pressure

Ratio < 2.65

3 3.1 On On On n/a

Pressure

Ratio < 3.65

When the circuit state becomes Pumpdown or Off, all VR

solenoids should be turned off.

Condenser Fan Control

Condenser fan control will vary in operation based on the Fan

VFD Conguration set point.

Table 50: Condenser Fan Control Congurations

Fan VFD

Conguration

Control Type Control

Mechanism

None Staging only Contactors

1st Fan VFD Staging and speed

control of 1st fan on

the circuit

Contactors and

VFD

All Fan VFD Staging and speed

control of all fans

Integrated VFD on

each motor

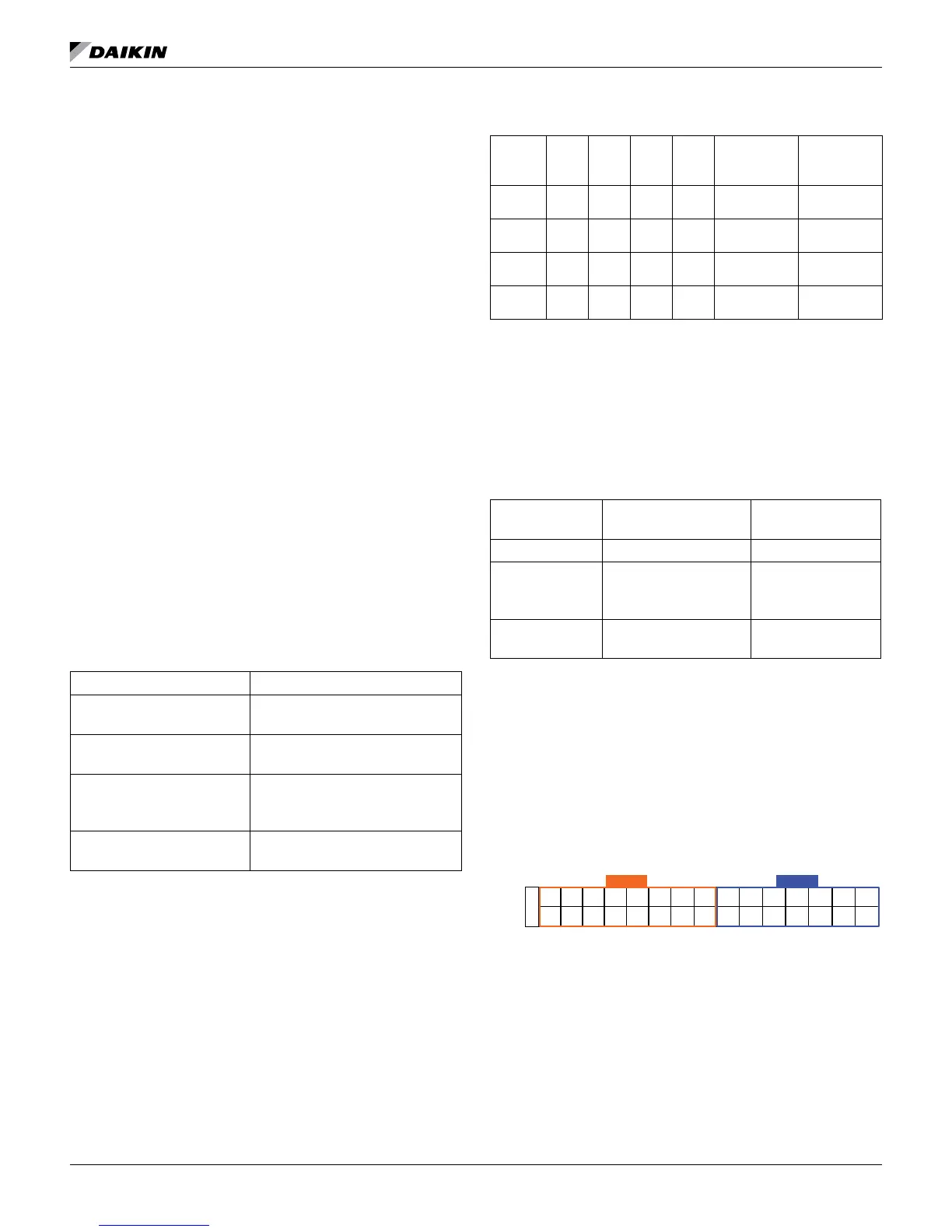

Physical Fan Layout

Fans are numbered as shown below (top view of chiller). Fan

numbers start on the left side of the circuit, closest to the

control box when facing the control box.

Circuit #1 fans start at 101 and can run through 116 depending

on the number of fans on the circuit. Circuit #2 fans start at 201

and can run through 214 depending on the number of fans on

the circuit.

Figure 63: Fan Numbering Diagram - Representative

NOTE: Number of fans vary by unit conguration

101

102

103

204

205

206

203

104

105

202

201

106

107

108

207

208

109

110

209

210

111

112

211

212

113

114

213

214

115

116

Control

Box

End

Circuit 1

Circuit 2

Loading...

Loading...