IOM 1242-2 • PATHFINDER

®

MODEL AWV CHILLERS 86 www.DaikinApplied.com

sysTem maInTenanCe

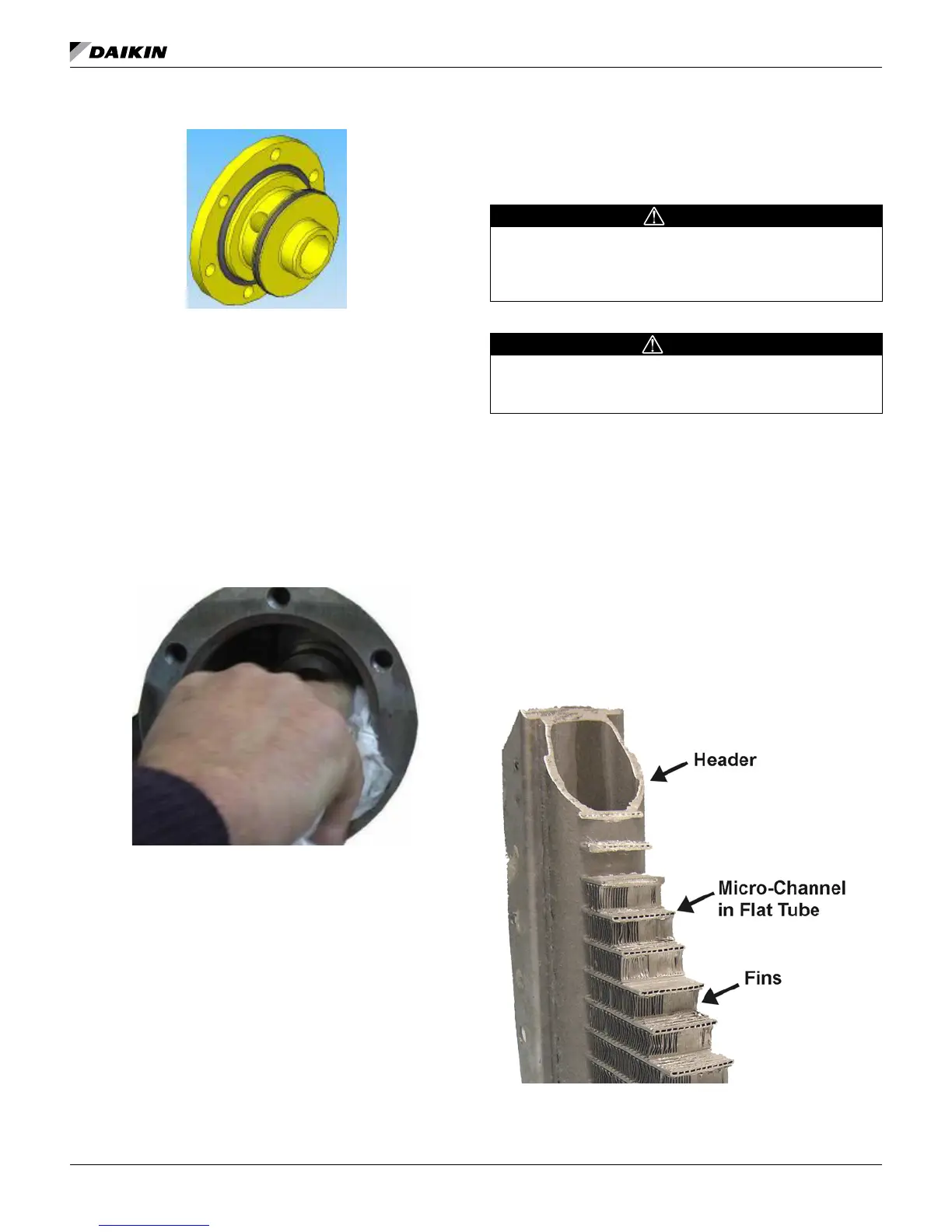

Figure 76: Oil Filter Housing Cover Plate

Oil lter assembly components are:

• Oil Filter – 250mm

• Oil Filter Housing Cover

• O-Ring – 89.5x3

• O-Ring – 76.1x3.4

• (6) M8 Bolts

Disassembly Procedure

1. Unscrew and remove two hex head side cover bolts 180°

apart. Insert M8 guide studs into the vacant holes.

2. Remove remaining bolts and oil lter housing cover.

3. Pull the oil lter off of the spigot and withdraw the oil lter

from the housing and clean the housing.

4. Clean oil lter housing cover plate and all other

components.

Fitting a New Oil Filter Element – Reassembly

Before reassembly, remove any paint from joint faces. Inspect

parts individually for damage and ensure they are completely

clean before laying them out on a clean surface in a logical

order ready for reassembly.

Use fresh refrigerant oil to lubricate parts during reassembly.

1. Install new O-rings on the oil lter housing cover.

2. Insert new oil lter into the housing, ensuring the lter

sits tightly on the sealing spigot.

3. Replace the oil lter housing cover.

4. Evacuate air and non-condensibles before valving

refrigerant back into the compressor.

Electrical Terminals

DANGER

Electric equipment can cause electric shock which will cause

severe personal injury or death. Turn off, lock out and tag all

power before continuing with following service. Panels can

have more than one power source.

CAUTION

Periodically check electrical terminals for tightness and tighten

as required. Always use a backup wrench when tightening

electrical terminals.

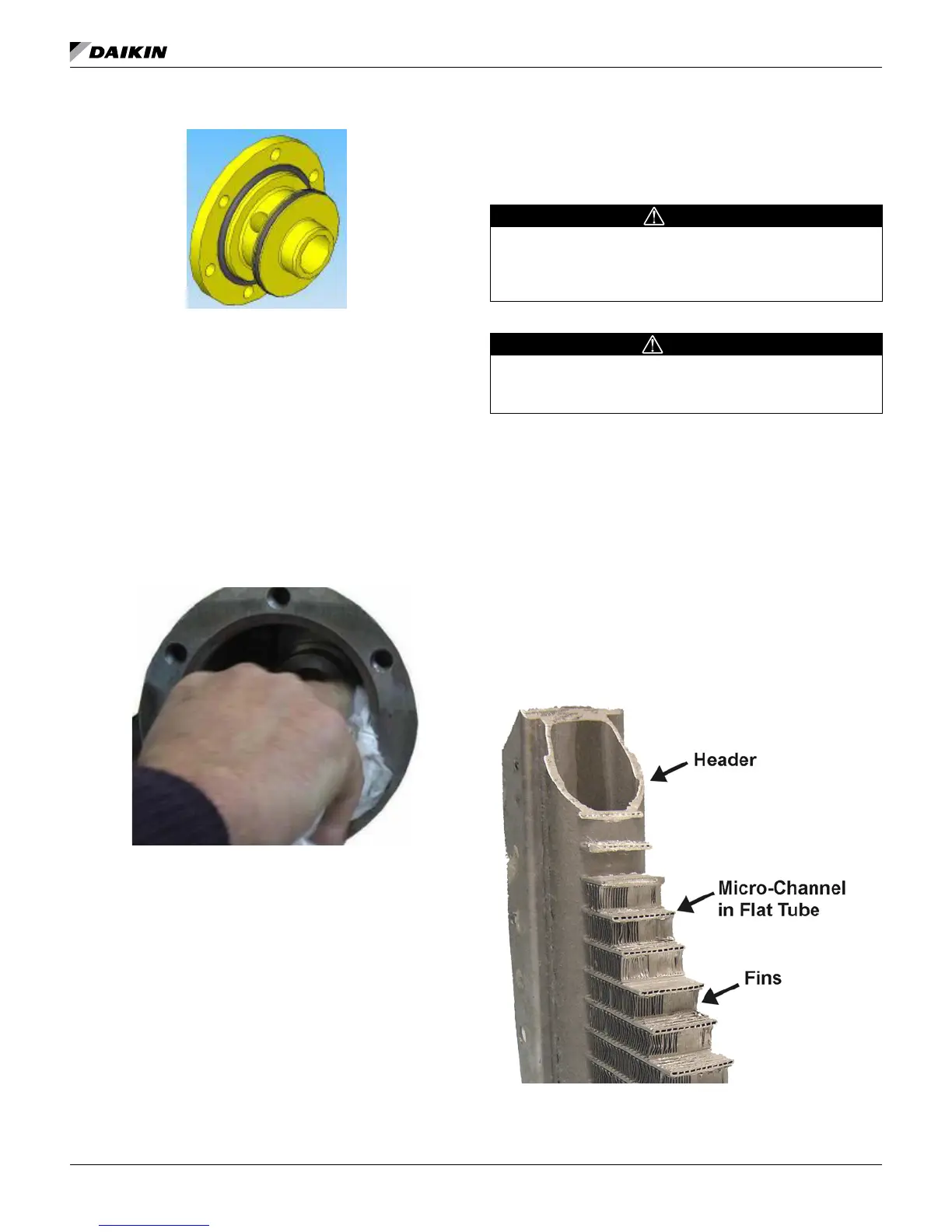

All-Aluminum Condenser Coils

The condenser coils are an all-aluminum design including the

connections, microchannels, ns (an oven brazing process

brazes the ns to the microchannel at tube), and headers

(see “Microchannel Coil Cross Section”), which eliminates

the possibility of corrosion normally found between dissimilar

metals of standard coils.

During the condensing process, refrigerant in the coil passes

through the microchannel at tubes, resulting in higher

efciency heat transfer from the refrigerant to the airstream. In

the unlikely occurence of a coil leak, contact Daikin Applied to

receive a replacement coil module.

Figure 77: Microchannel Coil Cross Section

Loading...

Loading...