IOM 1242-2 • PATHFINDER

®

MODEL AWV CHILLERS 14 www.DaikinApplied.com

InsTallaTIon and applICaTIon ConsIderaTIons

Chilled Water Piping

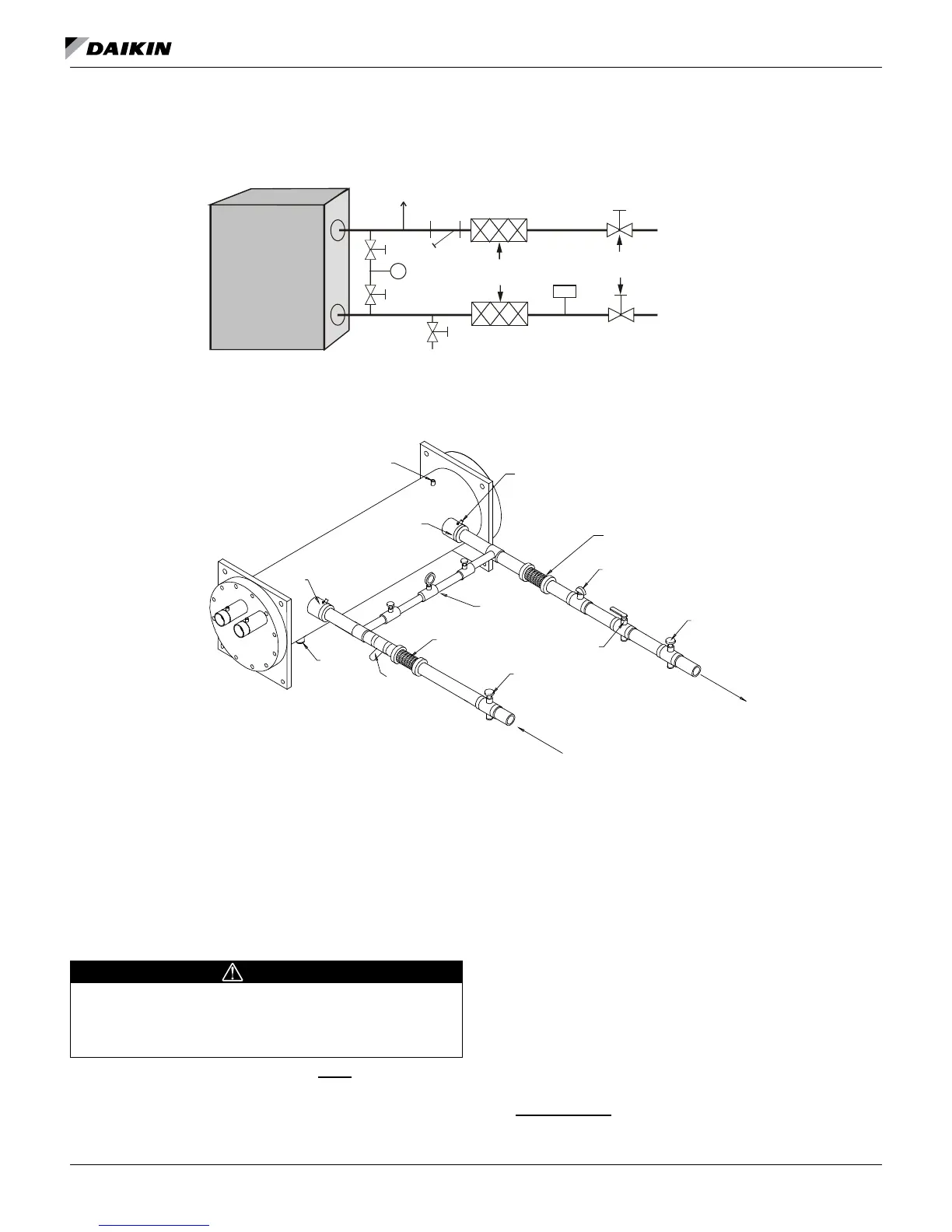

Figure 24: Typical Chilled Water Piping, Braze Plate

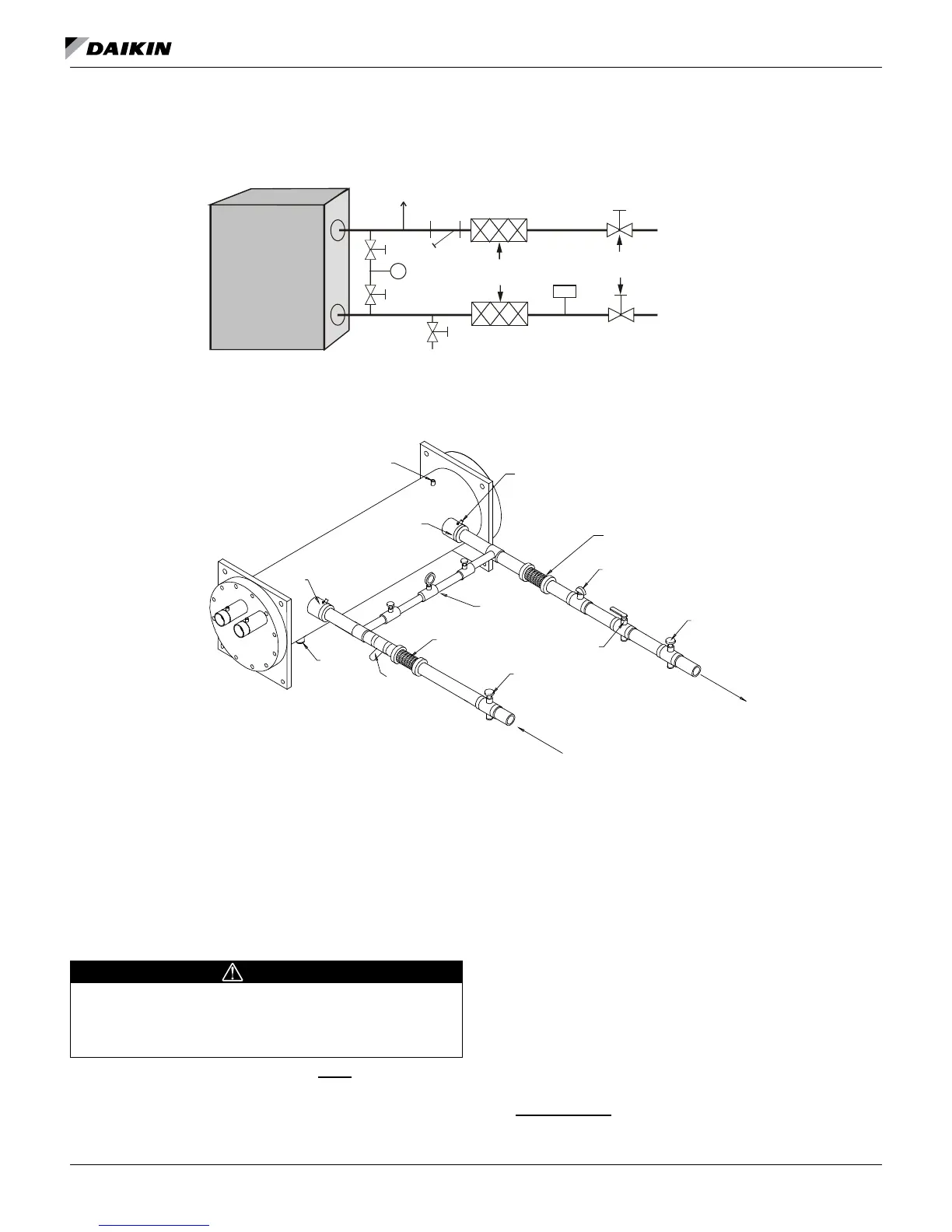

Figure 25: Typical Chilled Water Piping, Shell and Tube Evaporator

Startup procedures should conrm that the chilled water piping

system had been properly ushed out before being connected

to the chiller vessel.

All evaporators have OGS-type grooved water connections

(adhering to Standard AWWA C606) or optional ange

connections. The installing contractor must provide matching

mechanical connections. PVC and CPVC piping should not

be used. Be sure water inlet and outlet connections match

certied drawings and nozzle markings.

CAUTION

To prevent damage to the evaporator and potential chiller

failure, a supply strainer is required in the inlet water piping

which connects to the evaporator. This strainer must be

installed prior to operation of the chilled liquid pumps.

Field installed water piping to the chiller must include:

• A cleanable strainer installed at the water inlet to the

evaporator to remove debris and impurities before they

reach the evaporator. Install cleanable strainer within

5 feet (1500 mm) of pipe length from the evaporator

inlet connection and downstream of any welded

connections (no welded connections between strainer

and evaporator).

• AWV models require a strainer as specied in Inlet

Strainer Guidelines on page 15.

• A water ow switch must be installed in the horizontal

piping of the supply (evaporator outlet) water line to avoid

evaporator freeze-up under low or no ow conditions. The

ow switch may be ordered as a factory-installed option,

a eld-installed kit, or may be supplied and installed in the

eld. See page 16 for more information.

• Purge air from the water system before unit startup to

provide adequate ow through the evaporator.

• Adequate piping support, independent from the unit,

to eliminate weight and strain on the ttings and

connections.

It is recommended that the eld installed water piping to the

chiller include:

Air

Vent

Flow

Switch

Vibration

Eliminators

Drain

Outlet

Inlet

P

Isolation

Valves

Strainer

WELDED PIPE CONNECTIONS ARE NOT ALLOWED

BETWEEN THE STRAINER AND EVAPORATOR DUE

TO THE CHANCE OF SLAG ENTERING THE EVAPORATOR

LEAVING FLUID

TEMP. SENSOR

VENT

3/8” PIPE PLUG

VIBRATION

ELIMINATOR

FLOW

SWITCH

GATE

VALVE

FLOW

FLOW

GATE

VALVE

OUTLET

DRAIN

BALANCING

VALVE

VIBRATION

ELIMINATOR

WATER

STRAINER

VALVED

PRESSURE

GAUGE

PROTECT ALL FIELD PIPING

AGAINST FREEZING

INLET

WELDED PIPE CONNECTIONS ARE NOT ALLOWED

BETWEEN THE STRAINER AND EVAPORATOR DUE TO THE

CHANCE OF SLAG ENTERING THE EVAPORATOR

Loading...

Loading...