start-uP

Note: The settings of the hardware conguration jumpers are read when the controller is powered. Any changes to the jumper settings

require cycling power to the controller or sending a controller a reboot command through the network communications.

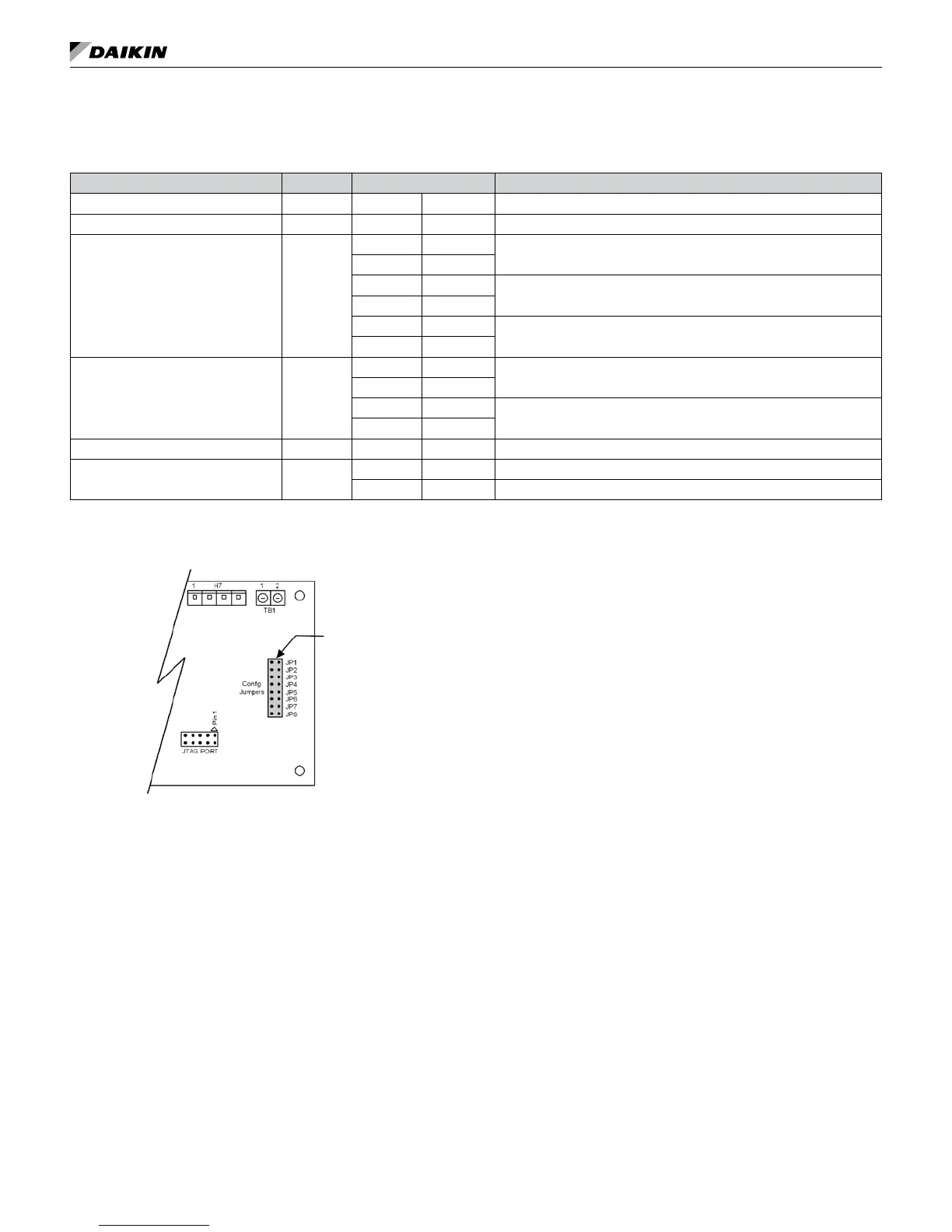

Table 11: I/O expansion module jumper settings

I/O Expansion Description Jumper(s) Jumper Setting Model

Not Used JP1 JP1 Open

–

Not Used JP2 JP2 Open

–

Secondary Heating

Options

JP3 & JP4

JP3 Open

None

JP4 Open

JP3 Shorted

Supplemental Electric Heat

JP4 Open

JP3 Open

Boilerless Electric Heat

JP4 Shorted

Cooling / Dehumidication

Options

JP5 & JP6

JP5 Shorted

Without Hydronic Cooling

JP6 Open

JP5 Open

Hydronic Cooling (Waterside Economizer)

JP6 Shorted

Not Used JP7 JP7 Open –

Lead Compressor Option JP8

JP8 Open Compressor #1 is Lead (factory default setting)

JP8 Shorted Compressor #2 is Lead

IM 1059-12 LARGE VERTICAL WSHP 25 www.DaikinApplied.com

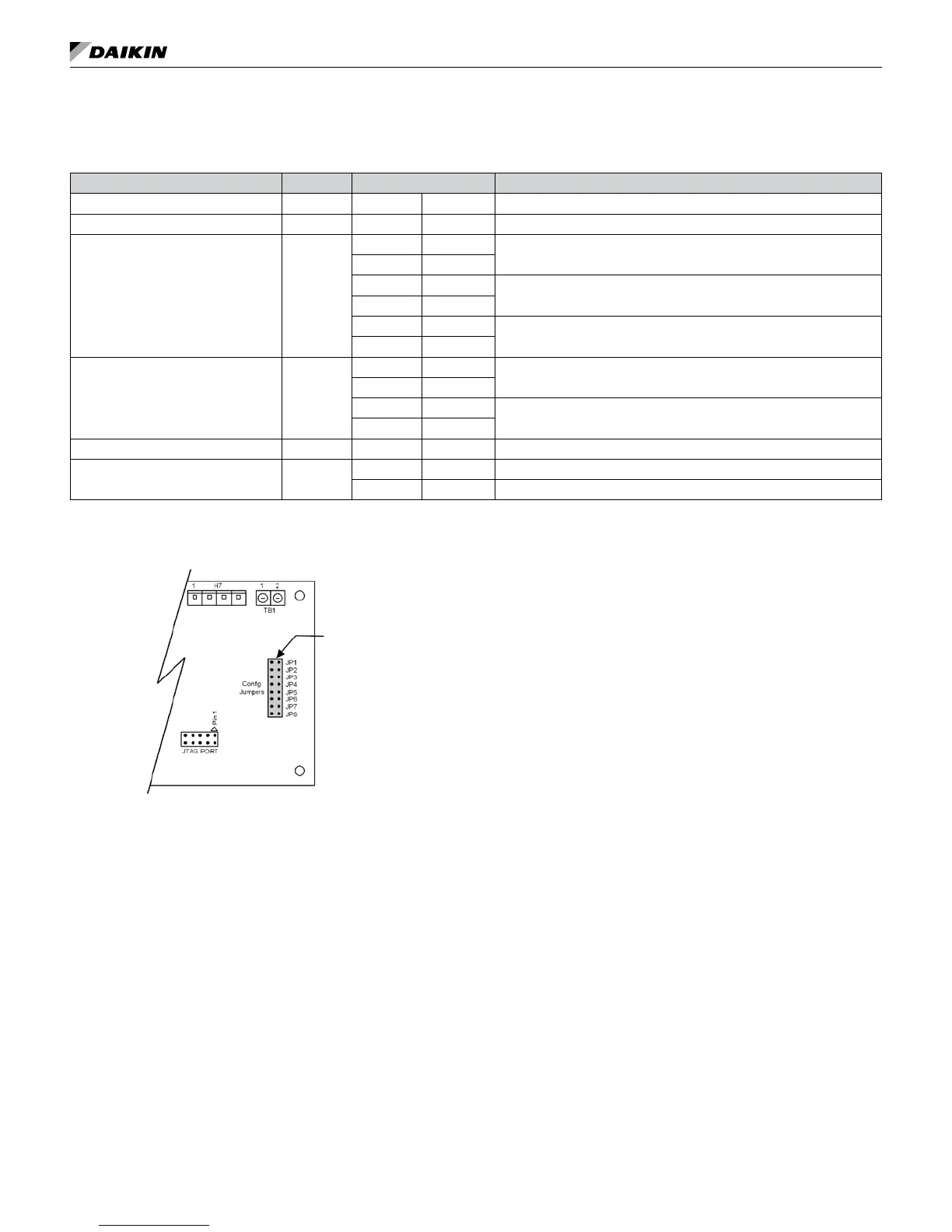

Figure 17: I/O expansion module configuration jumper

terminals

Jumper Terminals

3. Set thermostat to “Cool”. If the thermostat is an

automatic changeover type, simply set the cooling

temperature to the coolest position. On manual

changeover types additionally, select “Cool” at the

system switch.

Again, many conditioners have time delays which

protect the compressor(s) against short cycling.

After a few minutes of operation, check the

discharge grilles for cool air delivery. Measure

the temperature difference between entering and

leaving water. It should be approximately 1½

times greater than the heating mode temperature

difference. For example, if the cooling temperature

difference is 15°F (8°C), the heating temperature

difference should have been 10°F (5°C).

Without automatic ow control valves, target a

cooling temperature difference of 10°F to 14°F (5°C

to 8°C). Adjust the combination shutoff/balancing

valve in the return line to a water ow rate which will

result in the 10˚F to 14°F (5°C to 8°C) difference.

4. Set thermostat to “Heat.” If the thermostat is the

automatic changeover type, set system switch to the

“Auto” position and depress the heat setting to the

warmest selection. Some conditioners have built-in time

delays which prevent the compressor from immediately

starting. With most control schemes, the fan will

start immediately. After a few minutes of compressor

operation, check for warm air delivery at discharge

grille. If this is a “cold building” start-up, leave unit

running until return air to the unit is at least 65°F (18°C).

Measure the temperature difference between

entering and leaving air and entering and leaving

water. With entering water of 60°F to 80°F (16°C to

27°C), leaving water should be 6°F to 12°F (3.3°C

to 6.6°C) cooler (under full load conditions) and the

air temperature rise through the machine should not

exceed 35°F (19°C). If the air temperature exceeds

35°F (19°C), then the water ow rate is inadequate.

5. Check the elevation and cleanliness of the

condensate line. If the air is too dry for sufcient

dehumidication, slowly pour enough water into the

condensate pan to ensure proper drainage.

6. If the conditioner does not operate, check the

following points:

a. Is supply voltage to the machine compatible?

b. Is thermostat type appropriate?

c. Is thermostat wiring correct?

Loading...

Loading...