IM 1267-7 • PRECISELINE AIR HANDLER 18 www.DaikinApplied.com

Follow applicable piping design, sizing, and installation

information presented in ASHRAE Handbooks in the design

and installation of piping. Observe all local codes and industry

standards. Do not apply undue stress at the connection to the

coil headers. Support pipe work independently of the coils.

Hydronic coil guidelines are listed below.

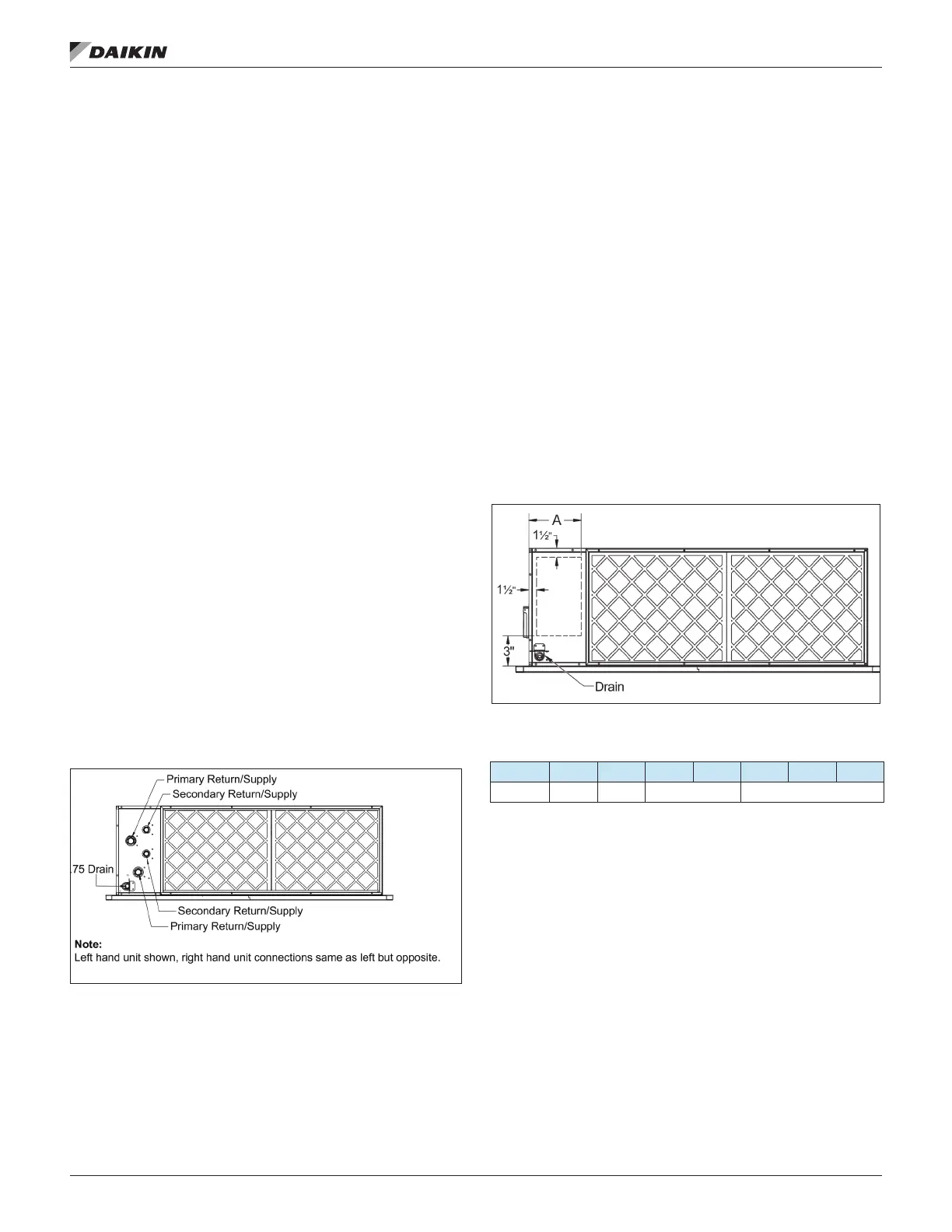

1. Horizontal units have hydronic coil stubs extend

connections made outside the cabinet. Stub locations

are the same for preheat and reheat coils. All stubs are

labeled on the panel.

2. Supply and return connections are copper FPT on unit

sizes 006 through 020 and copper sweat on sizes 030

through 100. See Horizontal Hydronic Coil Size and

Connection Type on page 67.

3. When making threaded connections, do not apply

undue stress to the stub. Use a backup wrench to avoid

damaging the braze joint between the stub and the valve

package or coil. When making sweat connections the

cabinet and valves must be protected from heat damage.

Use wet cloths or a heat shield to prevent heat from

soldering from burning the paint and insulation around

the stub.

4. Entering air below 40°F is not recommended.

Extended periods of temperatures below freezing can

cause some components to function improperly.

5. If fresh air and return air are to be heated by a hot water

coil, take care in the design of the system to provide

thorough mixing before air enters the coil.

Figure 33: Horizontal Coil Connections, Unit Sizes 006

Thru 020

Hydronic coil guidelines for units selected with the "No Valve

Package - Threaded Connections" option are listed below.

Refer to Table 5 on page 19 for connection size and type.

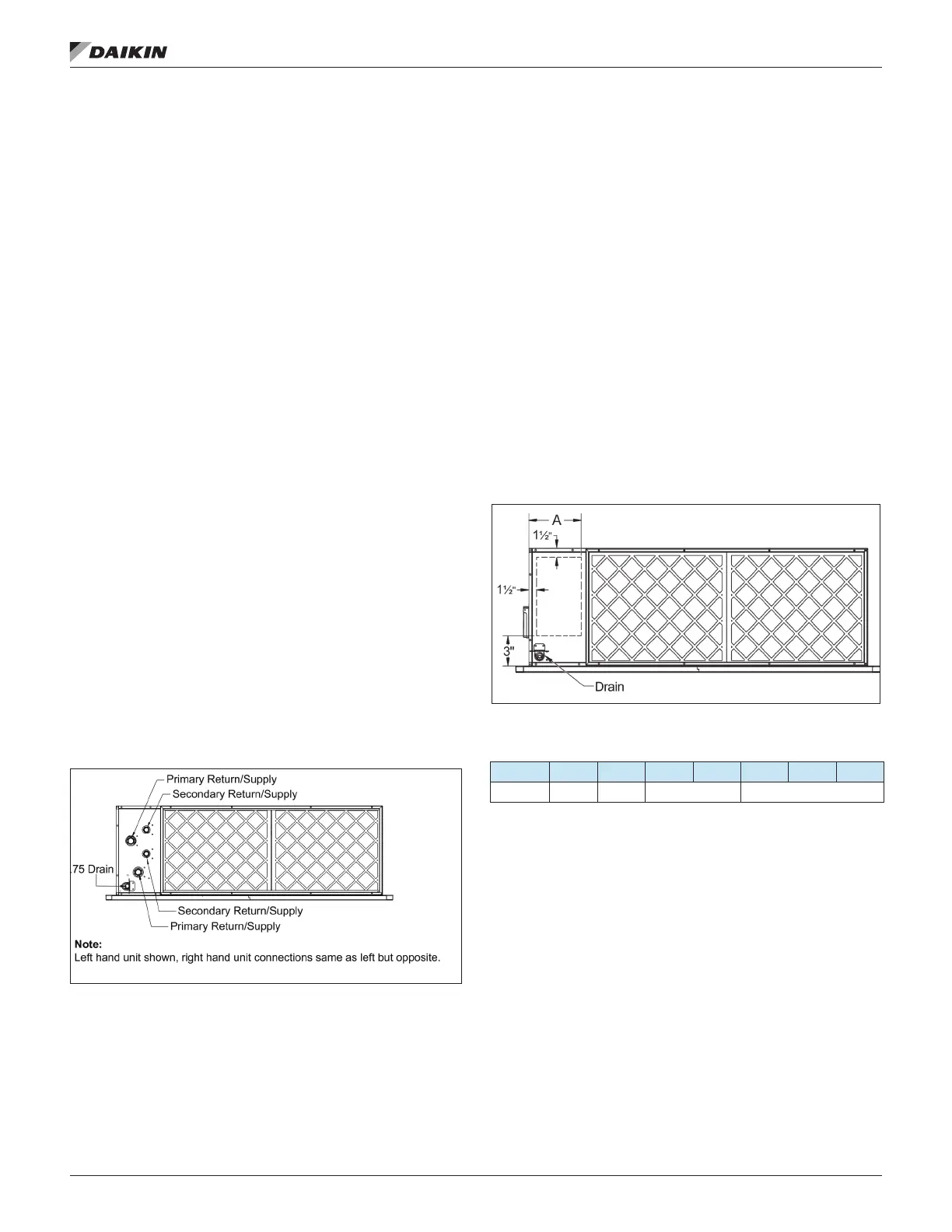

1. The supply and return coil stubs terminate inside the

made inside the cabinet. All stubs are factory labeled.

2. Internal hydronic coil connections are M-SWT.

be completely within the drill area on one of the factory

designated panels. (See Figure 34 below and Figure 35

on page 19) The diameter of the hole should be no

more than 1/2" larger than the pipe and gap around the

pipe should be sealed after installation.

4. When making the sweat connection the cabinet, coil and

drain pan must be protected from heat damage. Use wet

cloths or a heat shield to prevent the heat from soldering

from burning the paint and insulation around the stub.

Figure 34: Size 006 - 020 Hydronic Coil Drill Area - Front

Table 4: Size 006-020 Hydronic Coil Drill Area Dimensions

006 008 010 012 016 018 020

A 7.13 7.80 7.62 7.53

Loading...

Loading...