1.

2.

3.

Troubleshooting and Alarms

Troubleshooting

Table 26: Troubleshooting

Compressor does not start

Spindle is in “OFF” position

Waiting for power on delay

Cabinet air temperature is less than compressor cut-in temp.

Defrost is in progress

Line voltage is too low or too high

High condenser temperature

Change spindle position by rotating clockwise.

Check and wait untill “Pod” expiries.

Check cabinet air sensor temp. “att”

Check and wait untill dAt and dot expires.

Check line voltages are within low and high voltage limits speci-

ed under uLi, uLo and uHo.

Check for condenser sensor temp’ct1’ and congured condenser

block limit’cbL’.

Door is open or door contact is defective

Check “Fdt” and door status. Check that door contact is ok

Fan stopped due to high evaporator temp.

Check evaporator sensor temp. “Et1/Et2” and FLt.

Fan start delay and temp. after defrost

Check for ‘Fdd’ and “Ftd” parameters’ conguration

Controller in Initial Pull Down or Pull-down mode

Defrost is skipped during pull-down. Check the thermostat sta-

tus and congured pull-down duration.

Check alarm delay for temperature ‘Ltd /Htd’ and door ‘dod’

Does not maintain correct cabi-

net temperature

Check the S1 sensor and sensor alarm status

Check the controller potentimeter function

Frost is not fully melted during

defrost

Evaporator sensor position not proper Too long defrost intervals

Congured defrost time is too short

Check the position and tting of the evaporator sensor

Check for congured dii, dAi, dit and dAt values

Alarms

Alarms (advanced version only) Indication

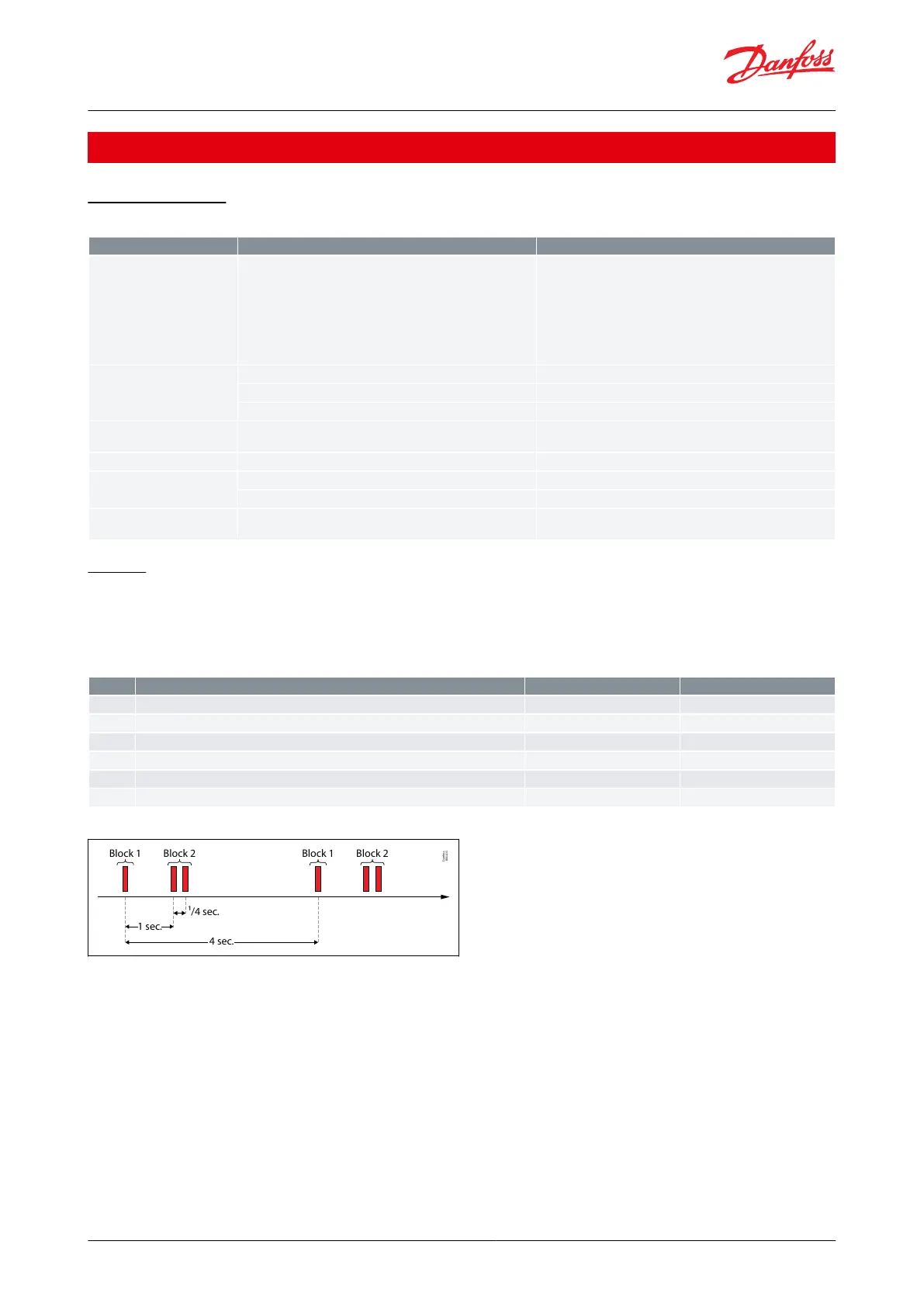

The EET controller indicates the fault or failure in the refrigeration system via an LED ashing pattern, sending a

message via MODBUS to KoolProg or any other tools. Below the LED blinking pattern for various alarms are stated:

Table 27: Alarms

Low and High temperature alarm

Figure 26: Indication of Line Voltage Alarm

Danfoss

80G415

4 sec.

1 sec.

¹/4 sec.

Block 1 Block 2 Block 1 Block 2

NOTE:

LED blinking every one second indicates power ON status and no alarm conditions.

Alarms to be interpreted as per block1 and block 2 blinking pattern as given in the table. After block 1 and Block

2 blinking there is about 2.5 seconds gap.

If there are multiple alarms, LED blinking pattern shows the alarm raised rst, next active alarm will be displayed

only when the rst raised alarm is xed.

Refrigeration controller, type EET series

© Danfoss | Climate Solutions | 2023.07 BC320944106159en-000301 | 28

Loading...

Loading...