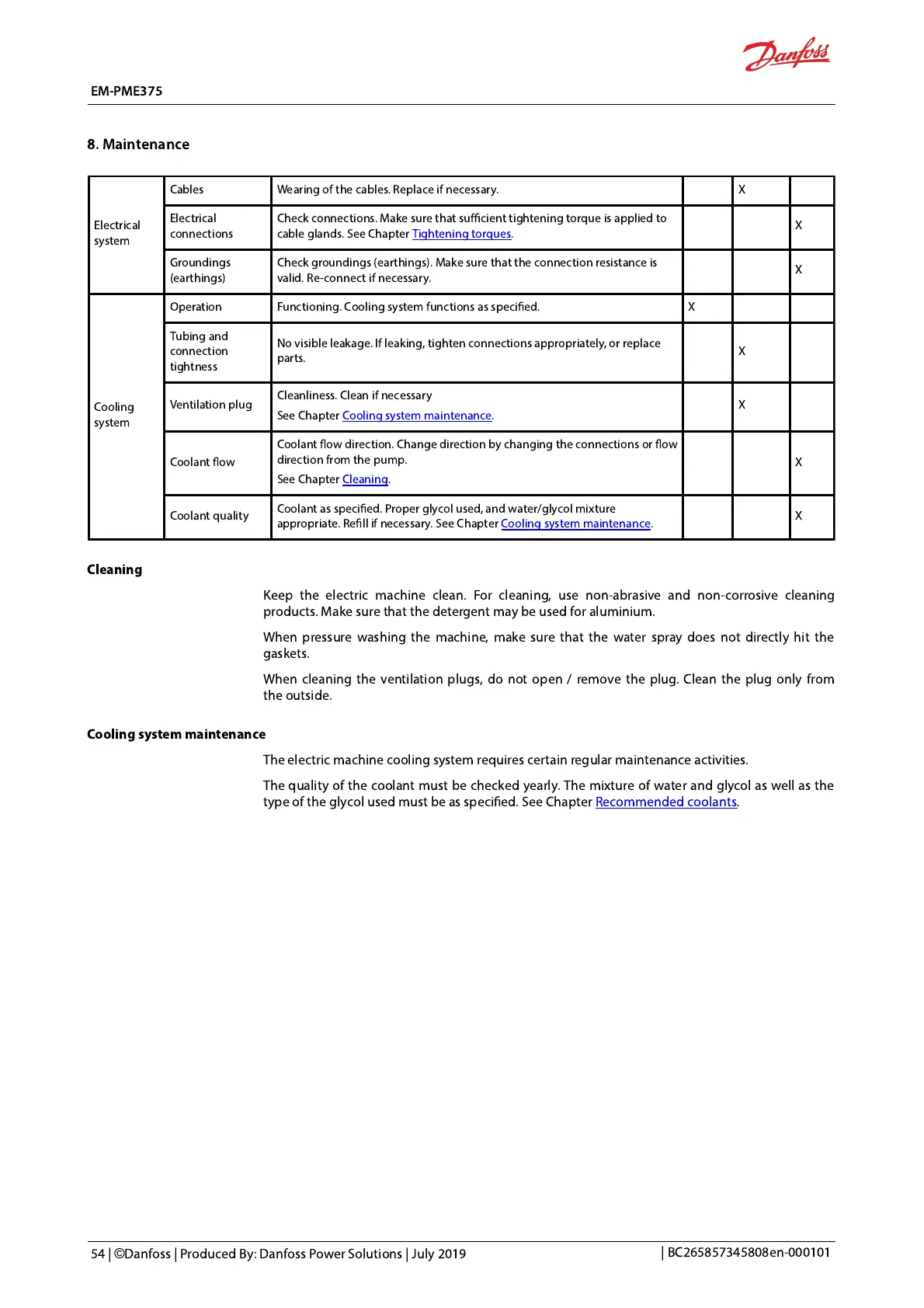

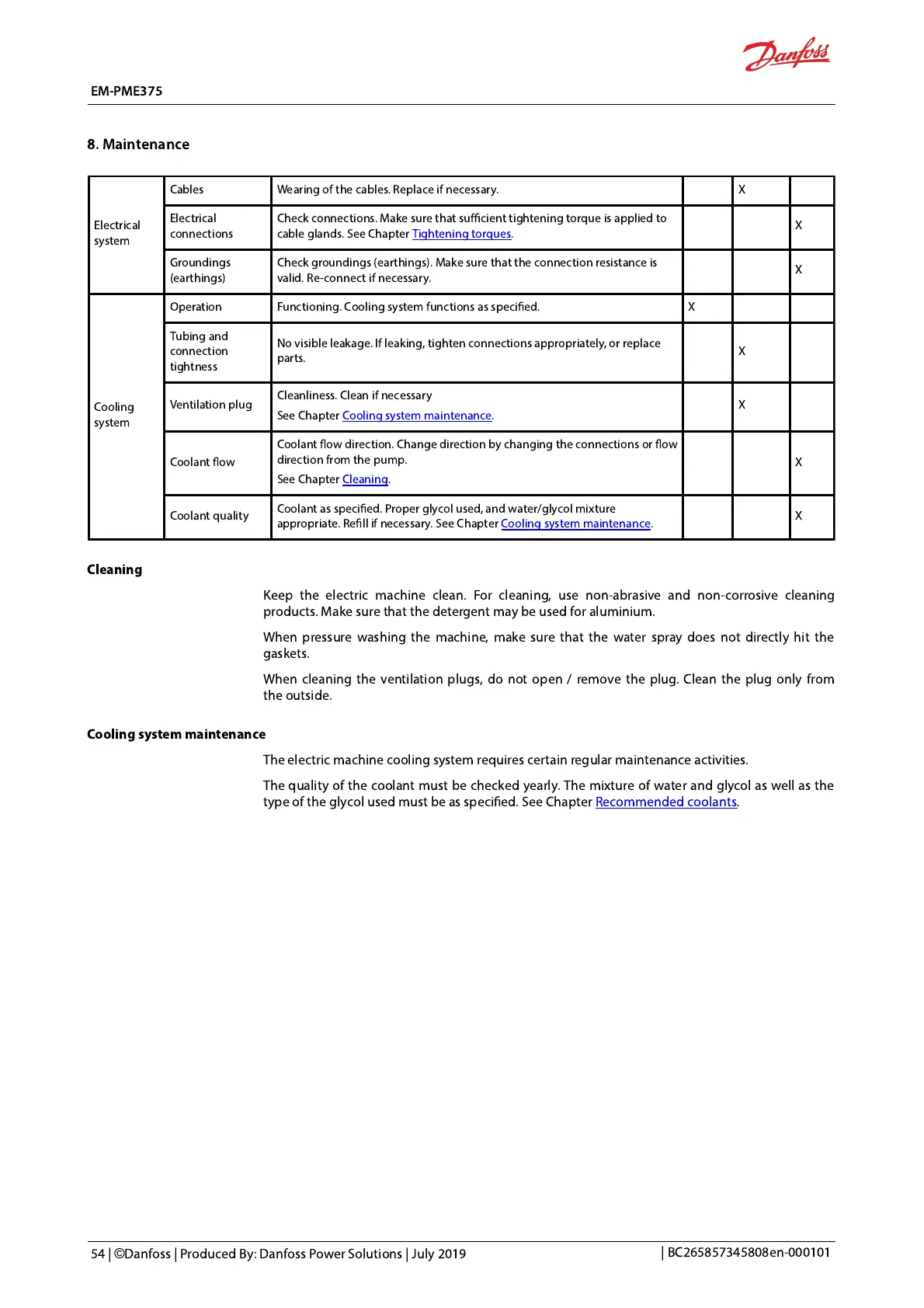

Electrical

system

Cables Wearing of the cables. Replace if necessary. X

Electrical

connections

Check connections. Make sure that sufficient tightening torque is applied to

cable glands. See Chapter Tightening torques.

X

Groundings

(earthings)

Check groundings (earthings). Make sure that the connection resistance is

valid. Re-connect if necessary.

X

Cooling

system

Operation Functioning. Cooling system functions as specied. X

Tubing and

connection

tightness

No visible leakage. If leaking, tighten connections appropriately, or replace

parts.

X

Ventilation plug

Cleanliness. Clean if necessary

See Chapter Cooling system maintenance.

X

Coolant ow

Coolant ow direction. Change direction by changing the connections or ow

direction from the pump.

See Chapter Cleaning.

X

Coolant quality

Coolant as specied. Proper glycol used, and water/glycol mixture

appropriate. Rell if necessary. See Chapter Cooling system maintenance.

X

Cleaning

Keep the electric machine clean. For cleaning, use non-abrasive and non-corrosive cleaning

products. Make sure that the detergent may be used for aluminium.

When pressure washing the machine, make sure that the water spray does not directly hit the

gaskets.

When cleaning the ventilation plugs, do not open / remove the plug. Clean the plug only

from

the

outside.

Cooling system maintenance

The electric machine cooling system requires certain regular maintenance activities.

The quality of the coolant must be checked yearly. The mixture of water and glycol as well as the

type of the glycol used must be as specied. See Chapter

Recommended coolants

.

Loading...

Loading...