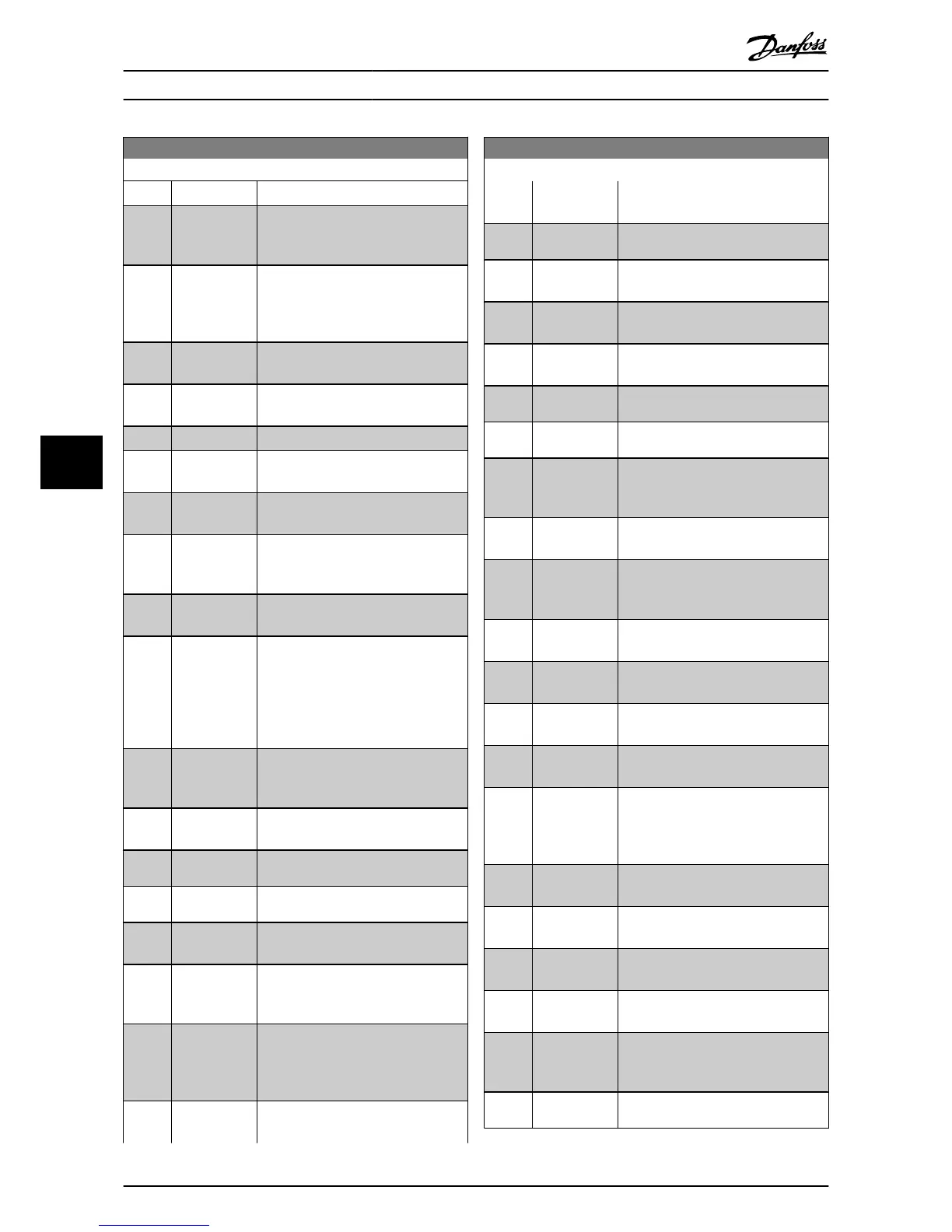

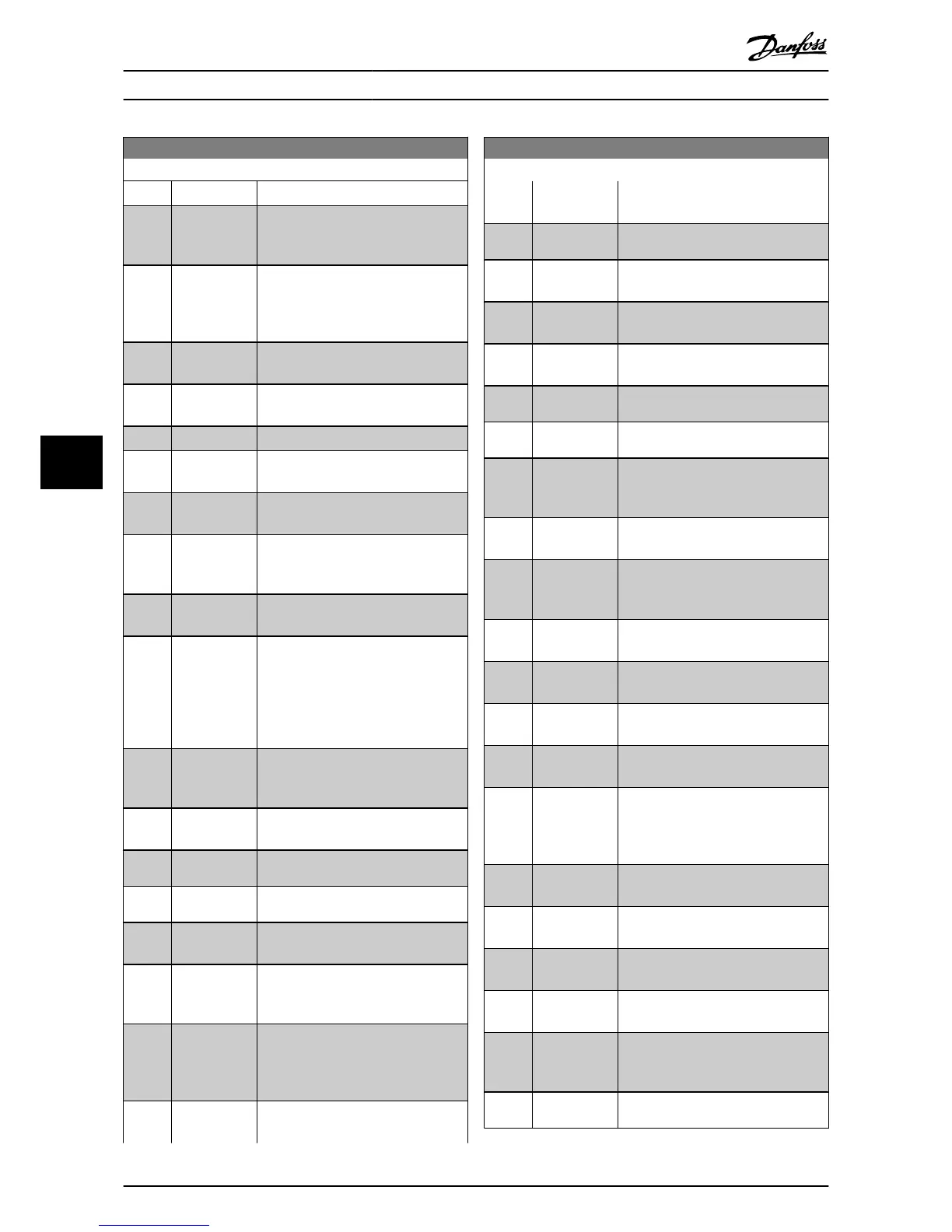

0-20 Display Line 1.1 Small

Option: Function:

[1603] Status Word Present status word

[1605] Main Actual

Value [%]

View the two-byte word sent with the

Status word to the bus Master reporting

the Main Actual Value.

[1609] Custom

Readout

View the user-defined readouts as

defined in par. 0-30 Custom Readout Unit,

par. 0-31 Custom Readout Min Value and

par. 0-32 Custom Readout Max Value.

[1610] Power [kW] Actual power consumed by the motor in

kW.

[1611] Power [hp] Actual power consumed by the motor in

HP.

[1612] Motor Voltage Voltage supplied to the motor.

[1613] Frequency Motor frequency, i.e. the output frequen-

cy from the frequency converter in Hz.

[1614] Motor Current Phase current of the motor measured as

effective value.

[1615] Frequency [%] Motor frequency, i.e. the output frequen-

cy from the frequency converter in

percent.

[1616] Torque [Nm] Present motor load as a percentage of

the rated motor torque.

[1617] Speed [RPM] Motor speed reference. Actual speed will

depend on slip compensation being

used (compensation set in par. 1-62 Slip

Compensation). If not used, actual speed

will be the value read in the display

minus motor slip.

[1618] Motor Thermal Thermal load on the motor, calculated

by the ETR function. See also parameter

group 1-9* Motor Temperature.

[1622] Torque [%] Shows the actual torque produced, in

percentage.

[1626] Power Filtered

[kW]

[1627] Power Filtered

[hp]

[1630] DC Link

Voltage

Intermediate circuit voltage in the

frequency converter.

[1632] Brake Energy /s Present brake power transferred to an

external brake resistor.

Stated as an instantaneous value.

[1633] Brake Energy /

2 min

Brake power transferred to an external

brake resistor. The mean power is

calculated continuously for the most

recent 120 seconds.

[1634] Heatsink Temp. Present heat sink temperature of the

frequency converter. The cut-out limit is

0-20 Display Line 1.1 Small

Option: Function:

95 ± 5° C; cutting back in occurs at 70 ±

5° C.

[1635] Inverter

Thermal

Percentage load of the inverters

[1636] Inv. Nom.

Current

Nominal current of the frequency

converter

[1637] Inv. Max.

Current

Maximum current of the frequency

converter

[1638] SL Controller

State

State of the event executed by the

control

[1639] Control Card

Temp.

Temperature of the control card.

[1643] Timed Actions

Status

[1650] External

Reference

Sum of the external reference as a

percentage, i.e. the sum of analog/pulse/

bus.

[1652] Feedback

[Unit]

Reference value from programmed

digital input(s).

[1653] Digi Pot

Reference

View the contribution of the digital

potentiometer to the actual reference

Feedback.

[1654] Feedback 1

[Unit]

View the value of Feedback 1. See also

par. 20-0*.

[1655] Feedback 2

[Unit]

View the value of Feedback 2. See also

par. 20-0*.

[1656] Feedback 3

[Unit]

View the value of Feedback 3. See also

par. 20-0*.

[1658] PID Output [%] Returns the Drive Closed Loop PID

controller output value in percent.

[1660] Digital Input Displays the status of the digital inputs.

Signal low = 0; Signal high = 1.

Regarding order, see par. 16-60 Digital

Input. Bit 0 is at the extreme right.

[1661] Terminal 53

Switch Setting

Setting of input terminal 53. Current = 0;

Voltage = 1.

[1662] Analog Input

53

Actual value at input 53 either as a

reference or protection value.

[1663] Terminal 54

Switch Setting

Setting of input terminal 54. Current = 0;

Voltage = 1.

[1664] Analog Input

54

Actual value at input 54 either as

reference or protection value.

[1665] Analog Output

42 [mA]

Actual value at output 42 in mA. Use

par. 6-50 Terminal 42 Output to select the

variable to be represented by output 42.

[1666] Digital Output

[bin]

Binary value of all digital outputs.

How to Programme the Frequ...

VLT

®

HVAC Drive Operating Instructions

66 MG.11.AD.02 - VLT

®

is a registered Danfoss trademark

7

Loading...

Loading...