Operating variable: Unit:

16-00 Control Word hex

16-01 Reference [Unit] [unit]

16-02 Reference % %

16-03 Status Word hex

16-05 Main Actual Value [%] %

16-10 Power [kW] [kW]

16-11 Power [hp] [HP]

16-12 Motor voltage [V]

16-13 Frequency [Hz]

16-14 Motor Current [A]

16-16 Torque [Nm] Nm

16-17 Speed [RPM] [RPM]

16-18 Motor Thermal %

16-20 Motor Angle

16-30 DC Link Voltage V

16-32 Brake Energy /s kW

16-33 Brake Energy /2 min kW

16-34 Heatsink Temp. C

16-35 Inverter Thermal %

16-36 Inv. Nom. Current A

16-37 Inv. Max. Current A

16-38 SL Controller State

16-39 Control Card Temp. C

16-40 Logging Buffer Full

16-50 External Reference

16-51 Pulse Reference

16-52 Feedback [Unit] [Unit]

16-53 Digi Pot Reference

16-60 Digital Input bin

16-61 Terminal 53 Switch Setting V

16-62 Analog Input 53

16-63 Terminal 54 Switch Setting V

16-64 Analog Input 54

16-65 Analog Output 42 [mA] [mA]

16-66 Digital Output [bin] [bin]

16-67 Pulse Input #29 [Hz] [Hz]

16-68 Freq. Input #33 [Hz] [Hz]

16-69 Pulse Output #27 [Hz] [Hz]

16-70 Pulse Output #29 [Hz] [Hz]

16-71 Relay Output [bin]

16-72 Counter A

16-73 Counter B

16-80 Fieldbus CTW 1 hex

16-82 Fieldbus REF 1 hex

16-84 Comm. Option Status hex

16-85 FC Port CTW 1 hex

16-86 FC Port REF 1 hex

16-90 Alarm Word

16-92 Warning Word

16-94 Ext. Status Word

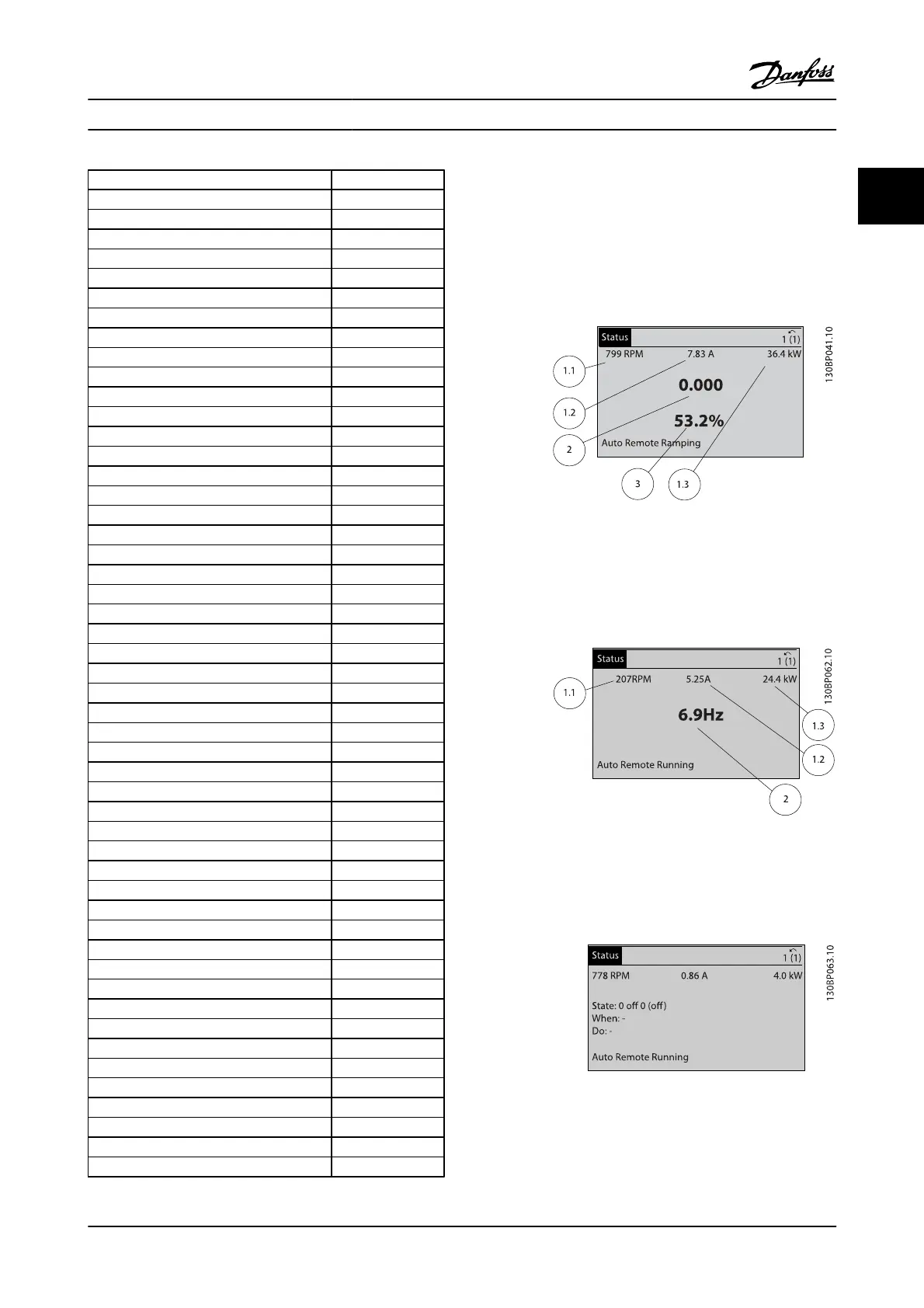

Status screen I:

This readout state is standard after start-up or initialization.

Use [INFO] to obtain information about the measurement

links to the displayed operating variables (1.1, 1.2, 1.3, 2 and

3).

See the operating variables shown on the screen in this

figure.

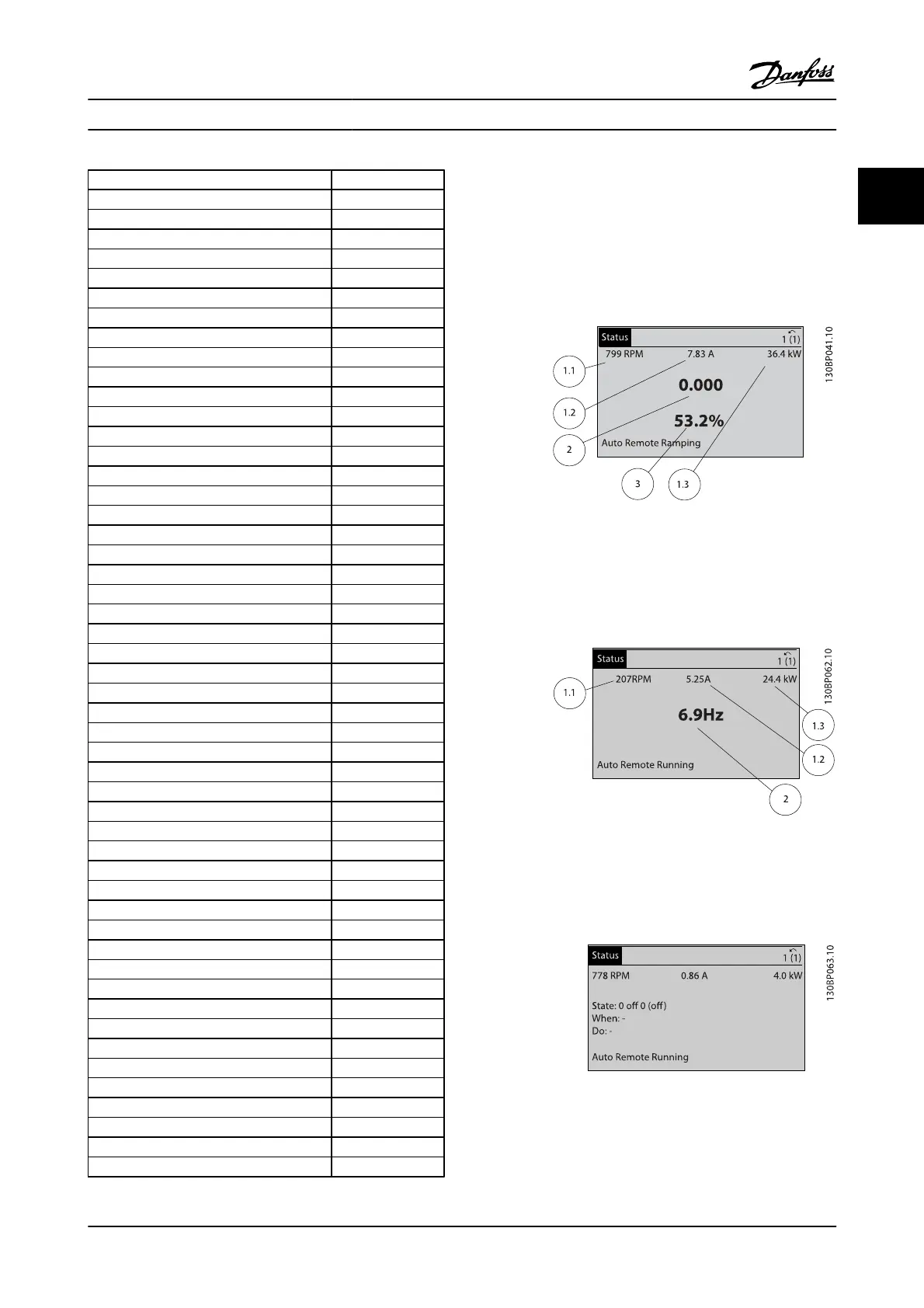

Status screen II:

See the operating variables (1.1, 1.2, 1.3 and 2) shown on the

screen in this figure.

In the example, Speed, Motor current, Motor power and

Frequency are selected as variables in the first and second.

Status screen III:

This state displays the event and action of the Smart Logic

Control. For further information, see section Smart Logic

Control.

How to Program FC 300 Programming Guide

MG.33.MA.22 - VLT

®

is a registered Danfoss trademark 2-5

2

Loading...

Loading...