VLT

®

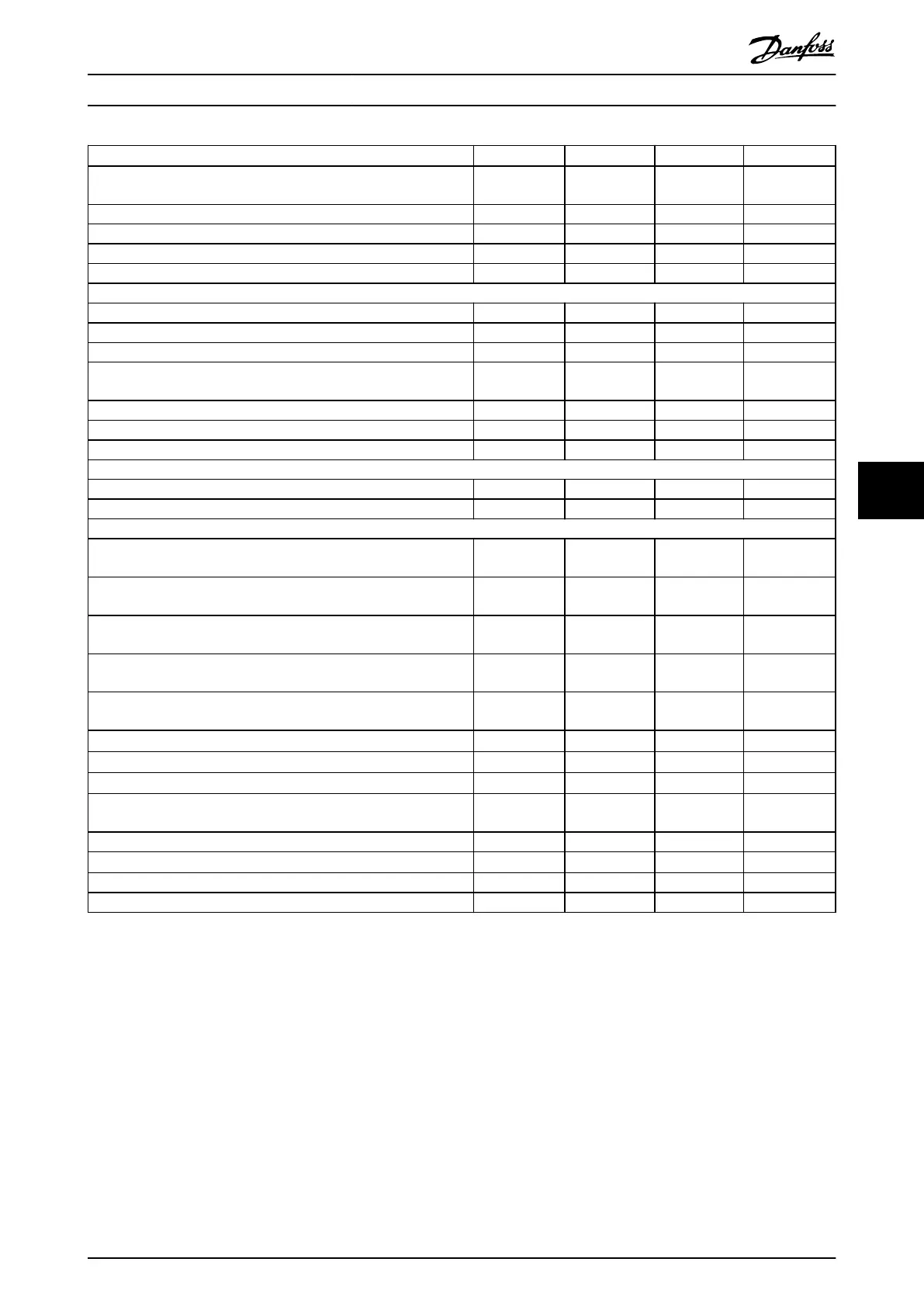

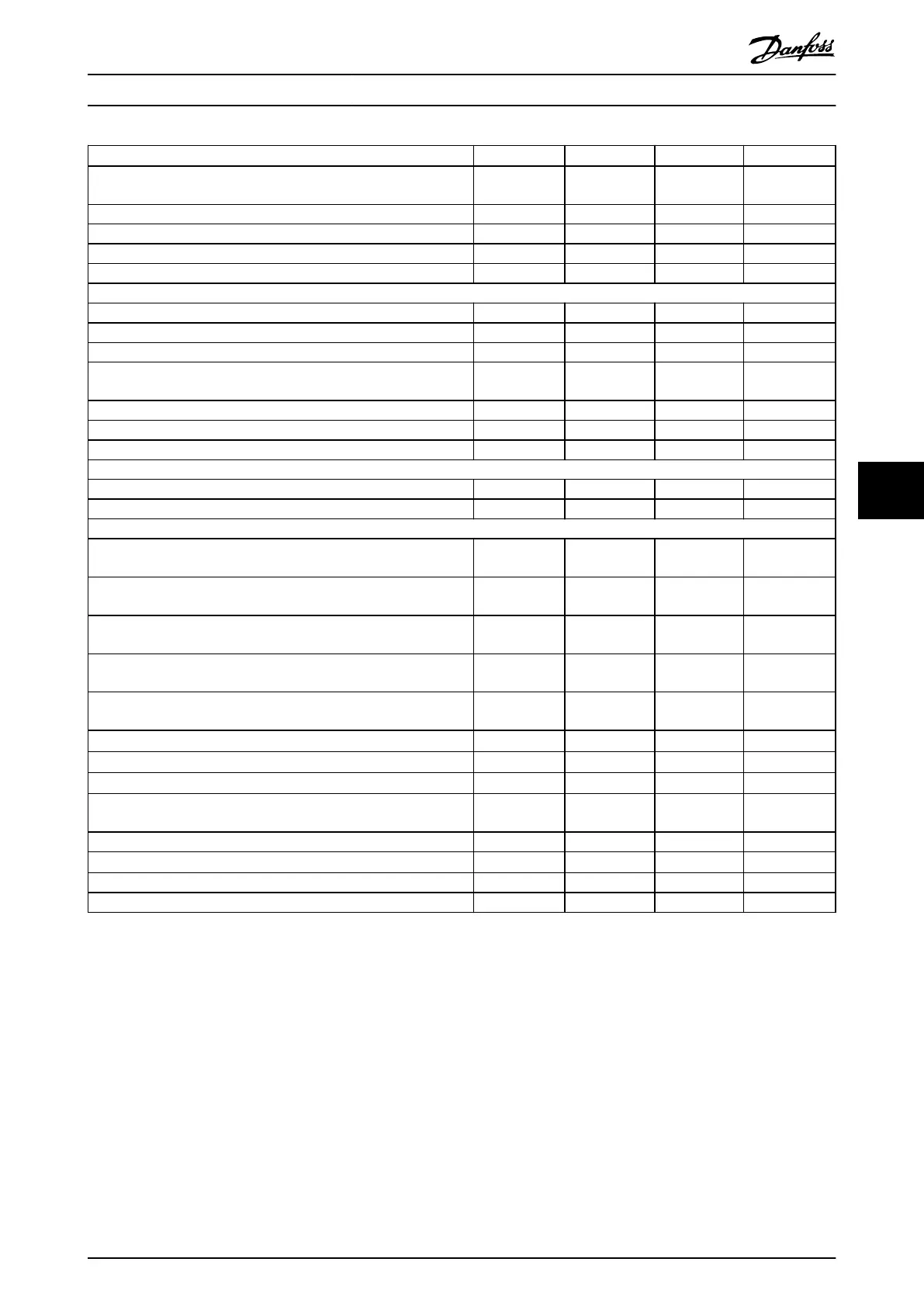

HVAC Drive FC 102

P500 P560 P630 P710

Normal overload NO NO NO NO

(Normal overload=110% current during 60 s)

Typical shaft output at 400 V [kW] 500 560 630 710

Typical shaft output at 460 V [hp] 650 750 900 1000

Typical shaft output at 480 V [kW] 560 630 710 800

Enclosure size F1/F3 F1/F3 F1/F3 F1/F3

Output current (3-phase)

Continuous (at 400 V) [A] 880 990 1120 1260

Intermittent (60 s overload) (at 400 V) [A] 968 1089 1680 1890

Continuous (at 460/480 V) [A] 780 890 1050 1160

Intermittent (60 s overload)

(at 460/480 V) [A]

858 979 1155 1276

Continuous kVA (at 400 V) [kVA] 610 686 776 873

Continuous kVA (at 460 V) [kVA] 621 709 837 924

Continuous kVA (at 480 V) [kVA] 675 771 909 1005

Maximum input current

Continuous (at 400 V) [A] 848 954 1079 1214

Continuous (at 460/480 V) [A] 752 858 1012 1118

Maximum number and size of cables per phase

- Motor [mm

2

(AWG)]

8x150 (8x300

mcm)

8x150 (8x300

mcm)

8x150 (8x300

mcm)

8x150 (8x300

mcm)

- Mains [mm

2

(AWG)] (F1)

8x240 (8x500

mcm)

8x240 (8x500

mcm)

8x240 (8x500

mcm)

8x240 (8x500

mcm)

- Mains [mm

2

(AWG)] (F3)

8x456 (8x900

mcm)

8x456 (8x900

mcm)

8x456 (8x900

mcm)

8x456 (8x900

mcm)

- Load share [mm

2

(AWG)]

8x120 (8x250

mcm)

8x120 (8x250

mcm)

8x120 (8x250

mcm)

8x120 (8x250

mcm)

- Brake [mm

2

(AWG)]

8x185 (8x350

mcm)

8x185 (8x350

mcm)

8x185 (8x350

mcm)

8x185 (8x350

mcm)

Maximum external mains fuses [A]

1)

1600 1600 2000 2000

Estimated power loss at 400 V [W]

2), 3)

10162 11822 12512 14674

Estimated power loss at 460 V [W]

2), 3)

8876 10424 11595 13213

Maximum added losses A1 RFI, circuit breaker or disconnect, and

contactor [W], (F3 only)

963 1054 1093 1230

Maximum panel options losses [W] 400 400 400 400

Eciency

3)

0.98 0.98 0.98 0.98

Output frequency [Hz] 0–590 0–590 0–590 0–590

Control card overtemperature trip [°C (°F)]

85 (185) 85 (185) 85 (185) 85 (185)

Table 7.2 Electrical Data for Enclosures F1/F3, Mains Supply 3x380–480 V AC

1) For fuse ratings, see chapter 10.5 Fuses and Circuit Breakers.

2) Typical power loss is at normal conditions and expected to be within

±

15% (tolerance relates to variety in voltage and cable conditions). These

values are based on a typical motor eciency (IE/IE3 border line). Lower eciency motors add to the power loss in the drive. Applies for

dimensioning of drive cooling. If the switching frequency is higher than the default setting, the power losses can increase. LCP and typical control

card power consumptions are included. For power loss data according to EN 50598-2, refer to drives.danfoss.com/knowledge-center/energy-

eciency-directive/#/. Options and customer load can add up to 30 W to the losses, though usually a fully loaded control card and options for

slots A and B each add only 4 W.

3) Measured using 5 m (16.5 ft) shielded motor cables at rated load and rated frequency. Eciency measured at nominal current. For energy

eciency class, see chapter 10.12 Eciency. For part load losses, see drives.danfoss.com/knowledge-center/energy-eciency-directive/#/.

Specications Design Guide

MG16C302 Danfoss A/S © 11/2017 All rights reserved. 49

7 7

Loading...

Loading...