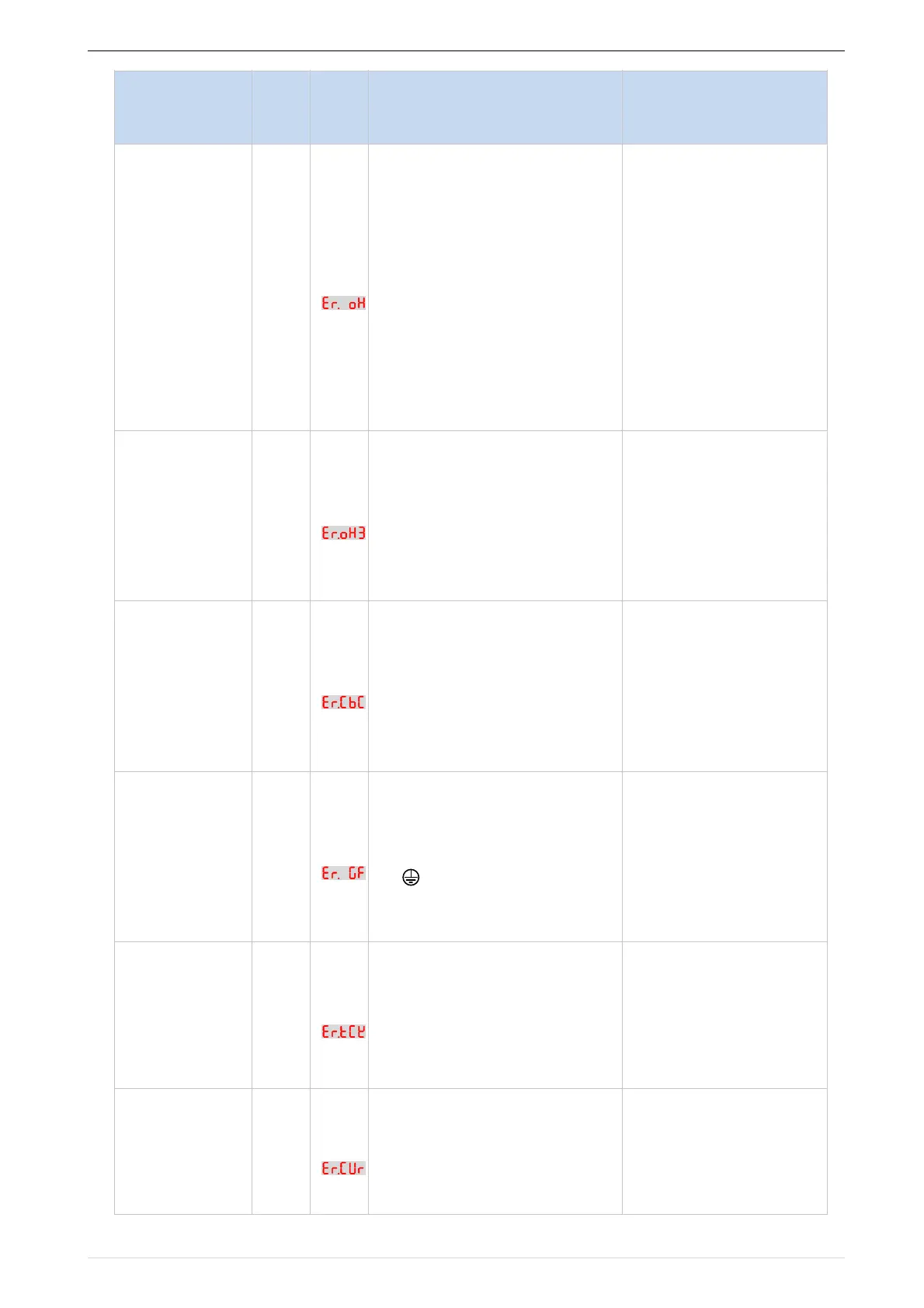

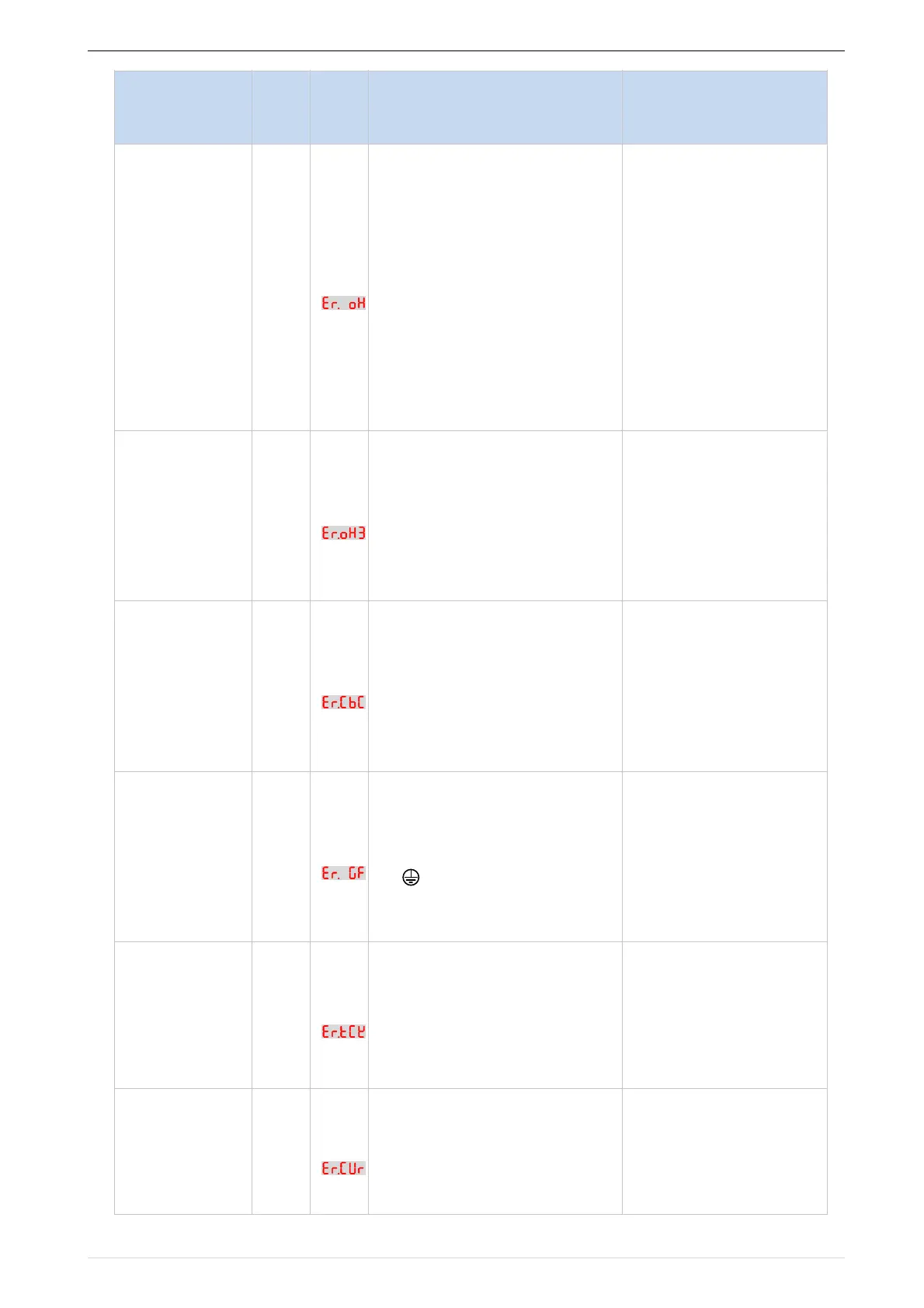

Chapter 6 Fault diagnosis and solutions VFD500 high performance vector control frequency inverter user manual

1: The ambient temperature is

too

high.

2: The air filter is blocked.

3: The fan is damaged.

4: The thermally sensitive

resistor of

the IGBT module is damaged.

5: The inverter IGBT module is

damaged

1:Lower the ambient

temperature.

2: Clean the air filter.

3: Replace thedamaged

fan.

4:Replace the damaged

thermally

sensitive resistor.

5: Replace the inverter

module.

1:The temperature sensor wiring

is loose

2:The motor temperature is too

high

3:Themotor temperature sensor

detects that the temperature is

greater than the set threshold.

1:check the temperature

sensor wiring

2:Improve the carrier

frequency, strengthen the

heat dissipation of the

motor, reduce the load,

and select a motor with

higher power.

3 : C h e c k i f t h e s e t

By wave

current

limitingfault

1: The load is too heavy or

locked-

rotor occurs on the motor.

2: The frequency inverter model

is of

too small power class

1: Reduce the load and

check

the motor and mechanical

condition.

2: Select a frequency

inverter of

higher power class.

1. Confirm the insulation

resistance of the motor. If

it is turned on, replace the

motor.

2. Check the power cable

of the motor to eliminate

the fault point.

3, reduce the carrier

frequency, install the

output reactor

module

temperature

detection fault

1, Temperature detection line

broken

2, Drive board is faulty

3. Main control board is faulty

4, The environmental

temperature is too low

1. Check the thermistor

wiring

2. Ask for technical

support

3. Ask for technical

support

4, manual intervention to

drive the temperature rise

1: The HALL device is faulty.

2: The drive board is faulty.

3: The control board is faulty

1: Replace the faulty

HALL

device.

2: Replace the faulty

drive board.

3: Ask for technical

support.

1. Motor burnout or insulation

aging

2, The cable is damaged and

contact, short circuit

3. The distributed capacitance of

the terminal and motor cable

is larger

motor cable

4, Hardware is damaged

Loading...

Loading...