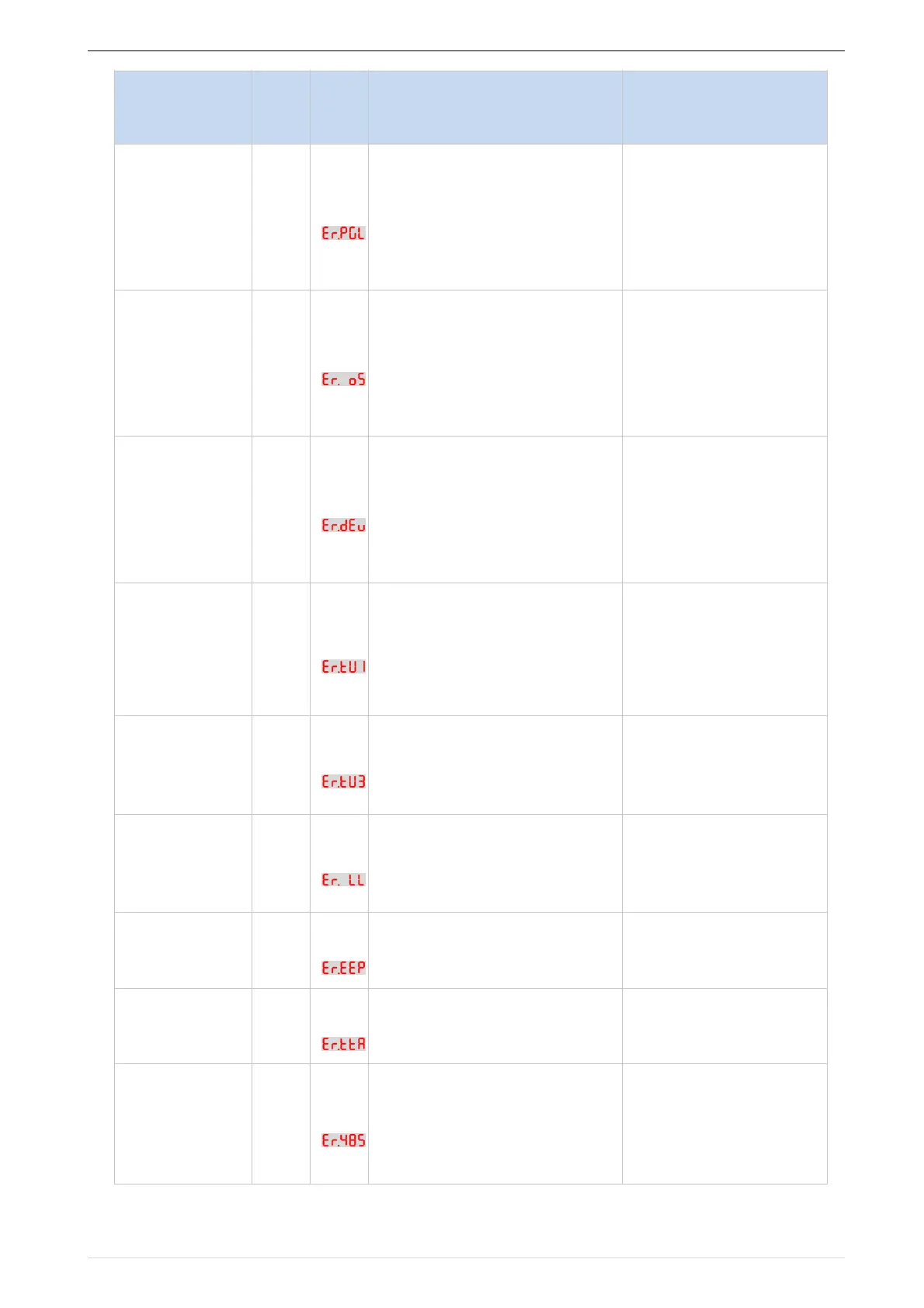

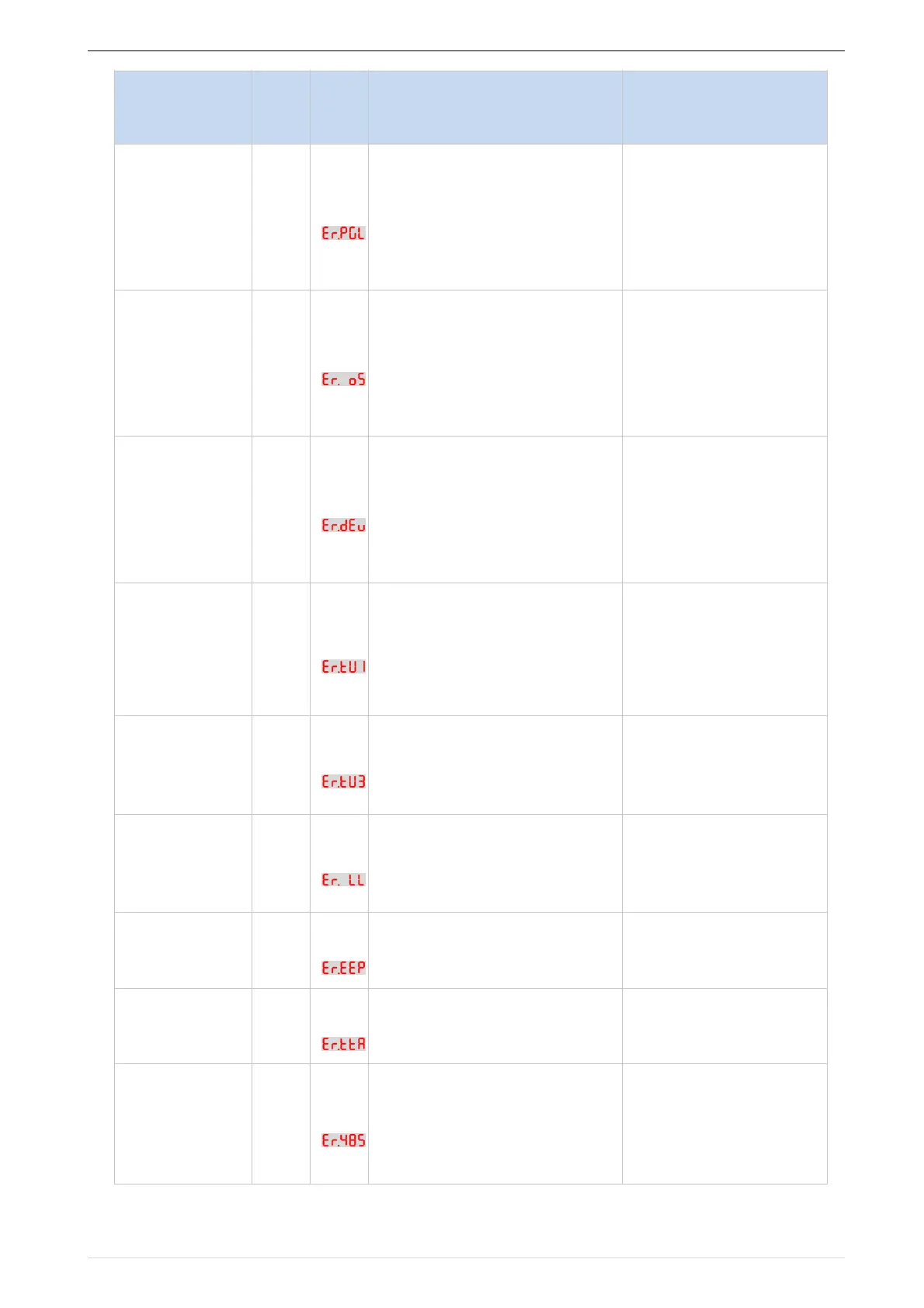

VFD500 high performance vector control frequency inverter user manual Chapter6 Fault diagnosis and solutions

1.

Motor locked

2.

Encoder pulse setting wrong

3.

Encoder offline

1 check motor and

mechanical condition

2 set correct parameter for

encoder

3 check encoder

connecting line

1: The encoder parameters are

setincorrectly.

2: The motor auto-tuning is

notperformed.

3: The over-speed

detectionparameters are set

incorrectly

1: Set the encoder

parametersproperly.

2: Perform the motor

auto-tuning.

3: Set the over-speed

detection

parameter correctly

based on the actual

Too large

speed

deviation

1: The encoder parameters are

setincorrectly.

2: The motor auto-tuning is

notperformed.

3: The detection parameters of

toolarge speed deviation are

setincorrectly.

1: Set the encoder

parameters

properly.

2: Perform the motor

auto-tuning.

3: Set the detection

parameters

correctly based on the

Motor

auto-tuning

fault 1

1: The motor parameters are not

set

according to the nameplate.

2: The motor auto-tuning times

out.

1: Set the motor

parameters according to

the nameplateproperly.

2: Check the cable

connecting between the

Frequency inverter and

themotor.

Motor

auto-tuning

fault 3

1: The motor parameters are not

set

according to the nameplate.

2: The motor auto-tuning times

out.

1: Set the motor

parametersaccording to

the nameplateproperly.

2: Check the cable

connecting between the

Frequency inverter and

1、The frequency inverter

running currentis lower than the

setting value.

1、Confirm whether the

load is off

2、Check that the load is

disconnected or the

parameter

setting is correct

1.

Eeprom Operate too

frequent

2.

The EEPROM chip is

damaged.

1.

Operate Eeprom

suitable

2.

Replace the main

control board

Inverter trial time arrival

1:Contact agent or

distributor

1, The work of the host computer

is not normal

2, The communication line is not

normal

3, The communication parameter

set is incorrect

1. Check the connection

of upper computer

2. Check the

communication

connection line

3. Set communication

parameters correctly

Loading...

Loading...