4.3 Visual Inspection

Table 4.1 lists a variety of conditions that require visual

inspection as part of any initial troubleshooting procedure.

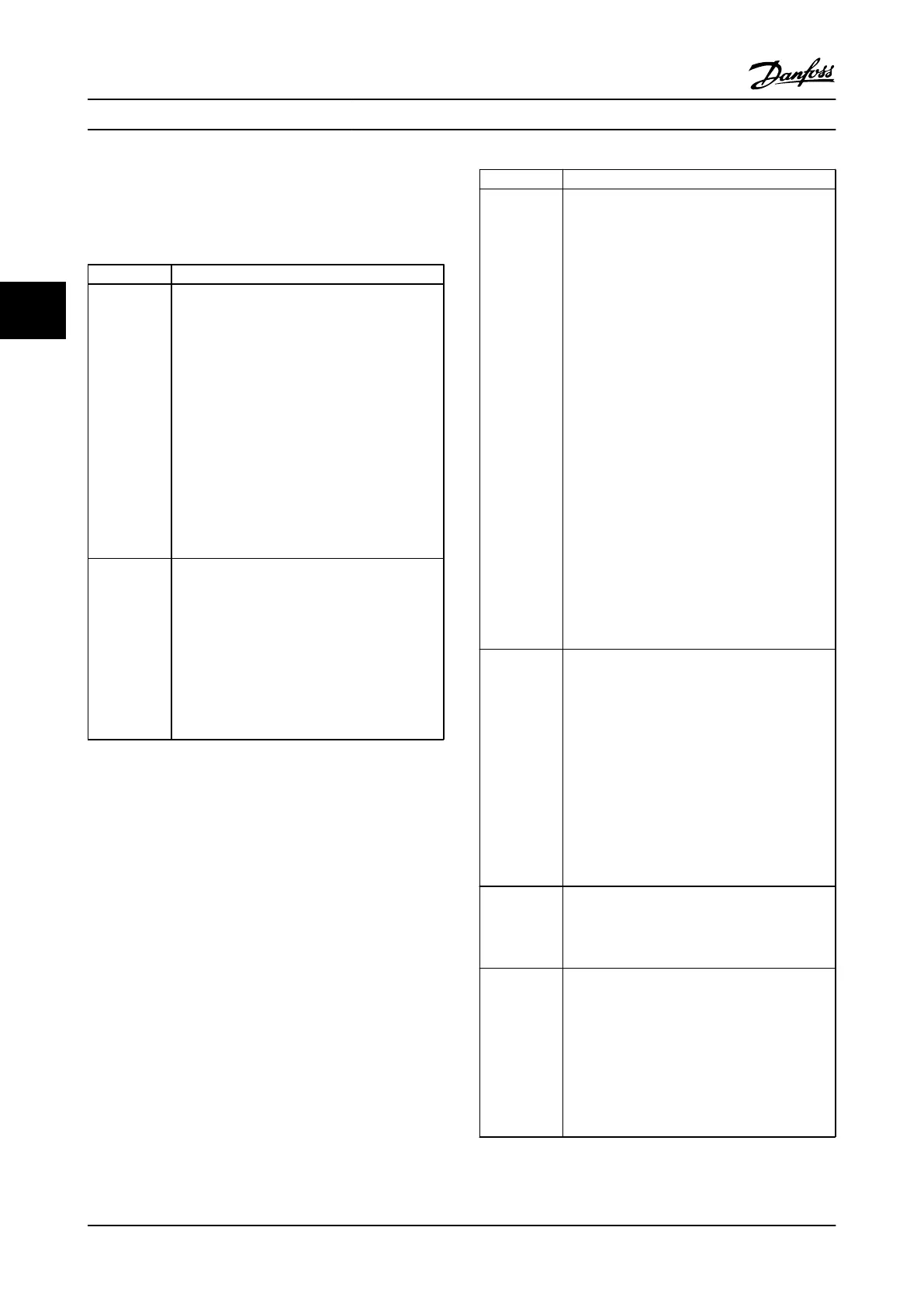

Inspect For Description

CT feedback

and other

auxiliary

equipment

•

Check the function and installation of current

sensors that provide feedback to the active

filter.

•

Ensure that CT feedback is connected to the

AFC card correctly: MK101 (5 A), MK108 (1 A).

•

Check for auxiliary equipment, switches,

disconnects, or input fuses/circuit breakers

that may reside on the input power side of

active filter.

•

Check the jumpers on the CT terminal.

•

Examine the operation and condition of these

items for possible causes of operational

faults.

Cable routing

•

Avoid routing cables through free air. Avoid

routing power line wiring and signal wiring in

parallel. If parallel routing is unavoidable, try

to maintain a separation of 150–200 mm (6–8

in) between the cables or separate them with

a grounded conductive partition.

•

For North American installations, control

wiring and power wiring must be in separate

conduits.

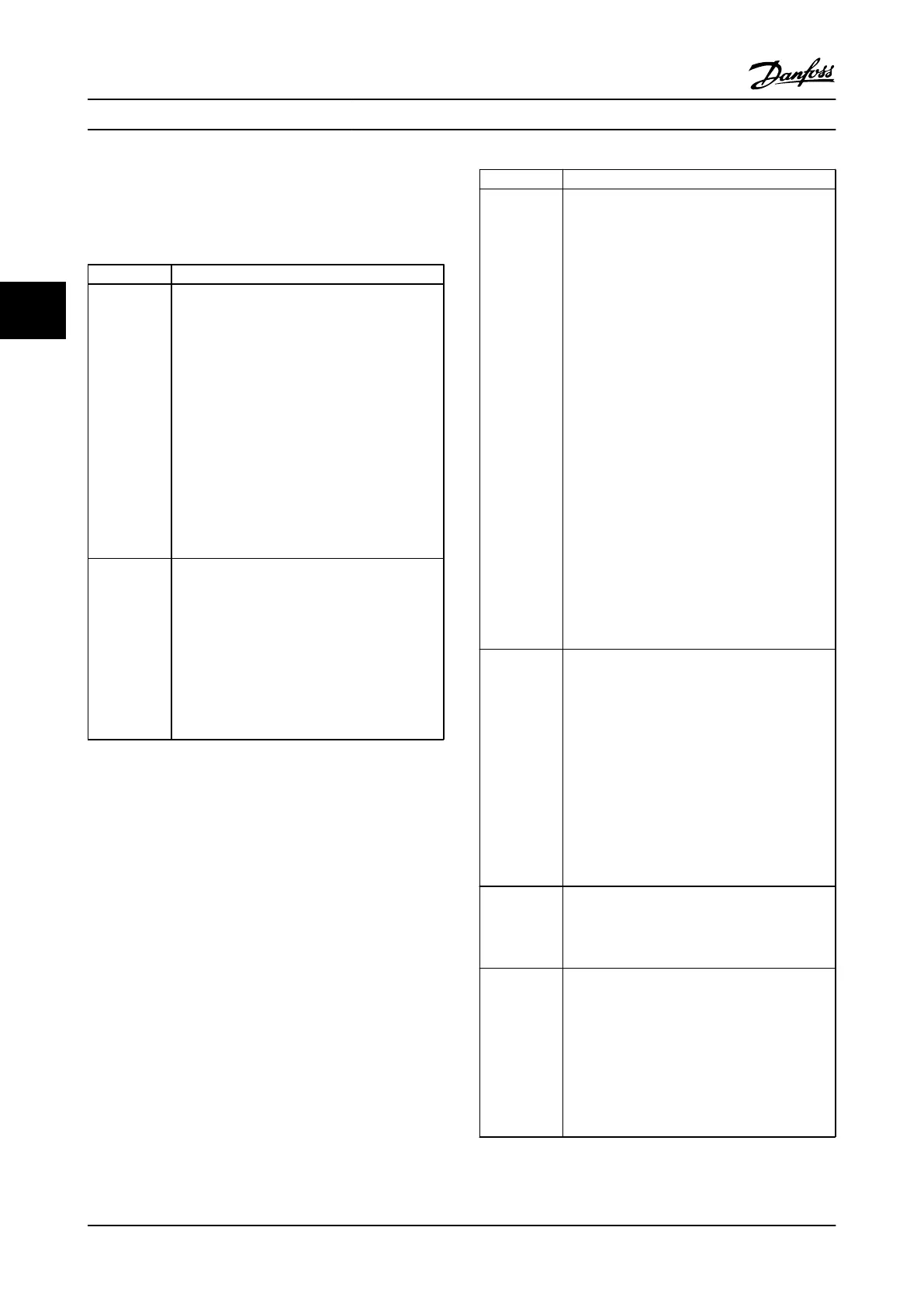

Inspect For Description

Control wiring

•

Check for broken or damaged wires and

connections.

•

Ensure that the CT polarity is correct. If

summation CTs are used, ensure polarity and

sequence is correct.

•

Check that CTs have the same rating

(summation CTs as well).

•

Check the voltage source of the signals.

•

Check that the maximum CT burden is not

exceeded through long wiring or small

square section.

•

Though not always necessary depending on

the installation conditions, the use of

shielded cable or a twisted pair is always

recommended.

•

Ensure the shield is terminated correctly.

Refer to the section on grounding shielded

cables in 2 Operator Interface and Active Filter

Control.

•

For North American installations, control

wiring and power wiring must be in separate

conduits.

Cooling and

clearances

•

Make sure the bottom connector plate is

installed.

•

Check the operational status of all cooling

fans and fan direction.

•

Check the door filters.

•

Check for blockage or constrained air

passages inside the enclosure and in the back

channel.

•

Check that required top clearance of 225 mm

(9 in) is present to ensure proper air flow for

cooling.

Display

•

Warnings, alarms, filter status, fault history

and many other important items are available

via the local control panel display on the

filter.

Interior

•

The active filter must be free of dirt, metal

chips, moisture, and corrosion.

•

Check for burned or damaged power

components or carbon deposits resulting

from catastrophic component failure.

•

Check for cracks or breaks in the housings of

power semiconductors and loose pieces of

broken component housings inside the unit.

Troubleshooting VLT Advanced Active Filter AAF006 D and E Frames Service Manual

4-2 MG90Z122 - VLT

®

is a registered Danfoss trademark

44

Loading...

Loading...