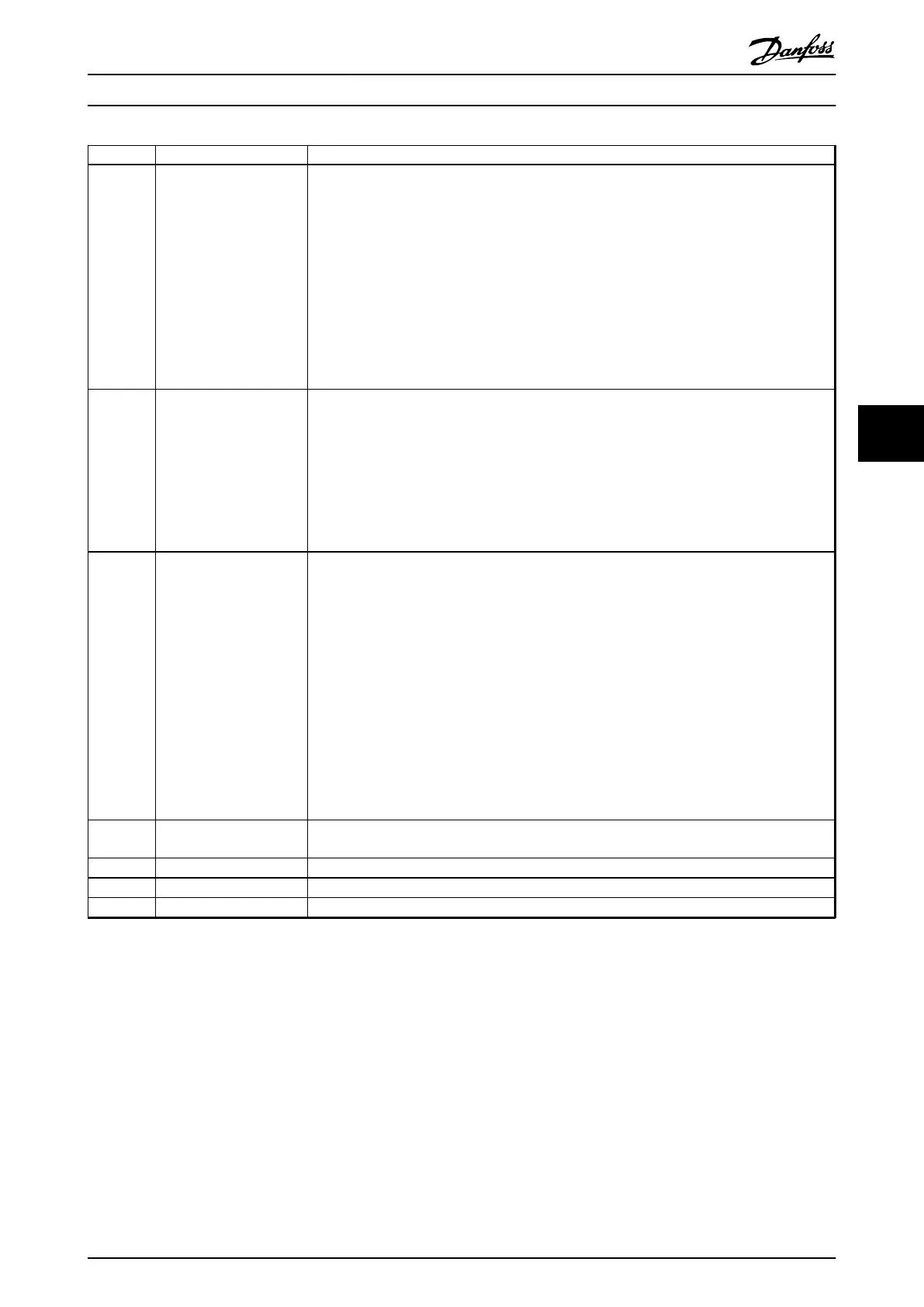

Group Title Function

4** Limits/Warnings Parameters used to program limits and warnings of operation including:

•

Allowable motor direction

•

Minimum and maximum motor speeds (e.g. in pump applications it is typical to program a

minimum speed to approx 30-40% to ensure pump seals are adequately lubricated at all

times, avoid cavitation and ensure adequate head is produced at all times to create flow)

•

Torque and current limits to protect the pump, fan or compressor driven by the motor

•

Warnings for low/high current, speed, reference, and feedback

•

Missing motor phase protection

•

Speed bypass frequencies including semi-automatic setup of these frequencies (e.g. to avoid

resonance conditions on cooling tower and other fans)

5** Digital In/Out Parameters used to program the functions of all

•

digital inputs

•

digital outputs

•

relay outputs

•

pulse inputs

•

pulse outputs

for terminals on the control card and all option cards.

6** Analog In/Out Parameters used to program the functions associated with all analog inputs and analog outputs

for the terminals on the control card and General Purpose I/O option (MCB 101) including:

•

Analog input live zero timeout function (which for example can be used to command a

cooling tower fan to operate at full speed if the condenser water return sensor fails)

•

Scaling of the analog input signals (for example to match the analog input to the mA and

pressure range of a static duct pressure sensor)

•

Filter time constant to filter out electrical noise on the analog signal which can sometimes

occur when long cables are installed

•

Function and scaling of the analog outputs (for example to provide an analog output

representing motor current or kW to an analog input of a DDC controller) and to configure

the analog outputs to be controlled by the BMS via a high level interface (HLI) (e.g. to

control a chilled water valve) including ability to define a default value of these outputs in

the event of the HLI failing

8** Communication and

Options

Parameters used for configuring and monitoring functions associated with the serial communi-

cations/high level interface to the frequency converter

9** Profibus Parameters only applicable when a Profibus option is installed.

10** CAN Fieldbus Parameters only applicable when a DeviceNet option is installed.

11** LonWorks Parameters only applicable when a Lonworks option is installed.

How to Programme VLT HVAC Drive FC 102 Operating Instructions

MG11F402 - Rev. 2013-12-16 81

6 6

Loading...

Loading...