•

When factory installed optional equipment is

wired to terminal 27, do not remove that wiring.

2.4.5.7 Terminal 53 and 54 Switches

•

Analog input terminals 53 and 54 can select

either voltage (0 to 10 V) or current (0/4–20 mA)

input signals

•

Remove power to the adjustable frequency drive

before changing switch positions.

•

Set switches A53 and A54 to select the signal

type. U selects voltage, I selects current.

•

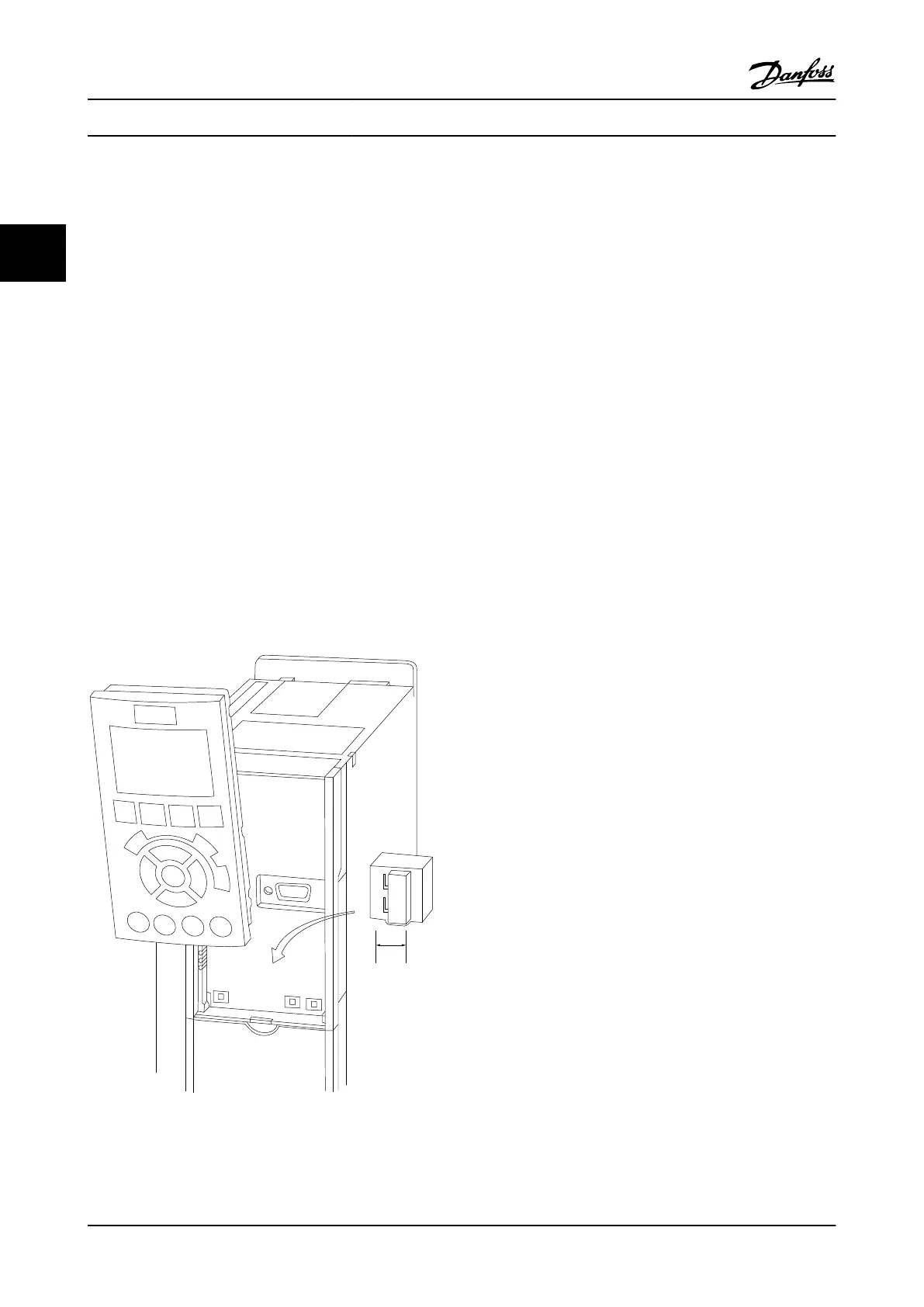

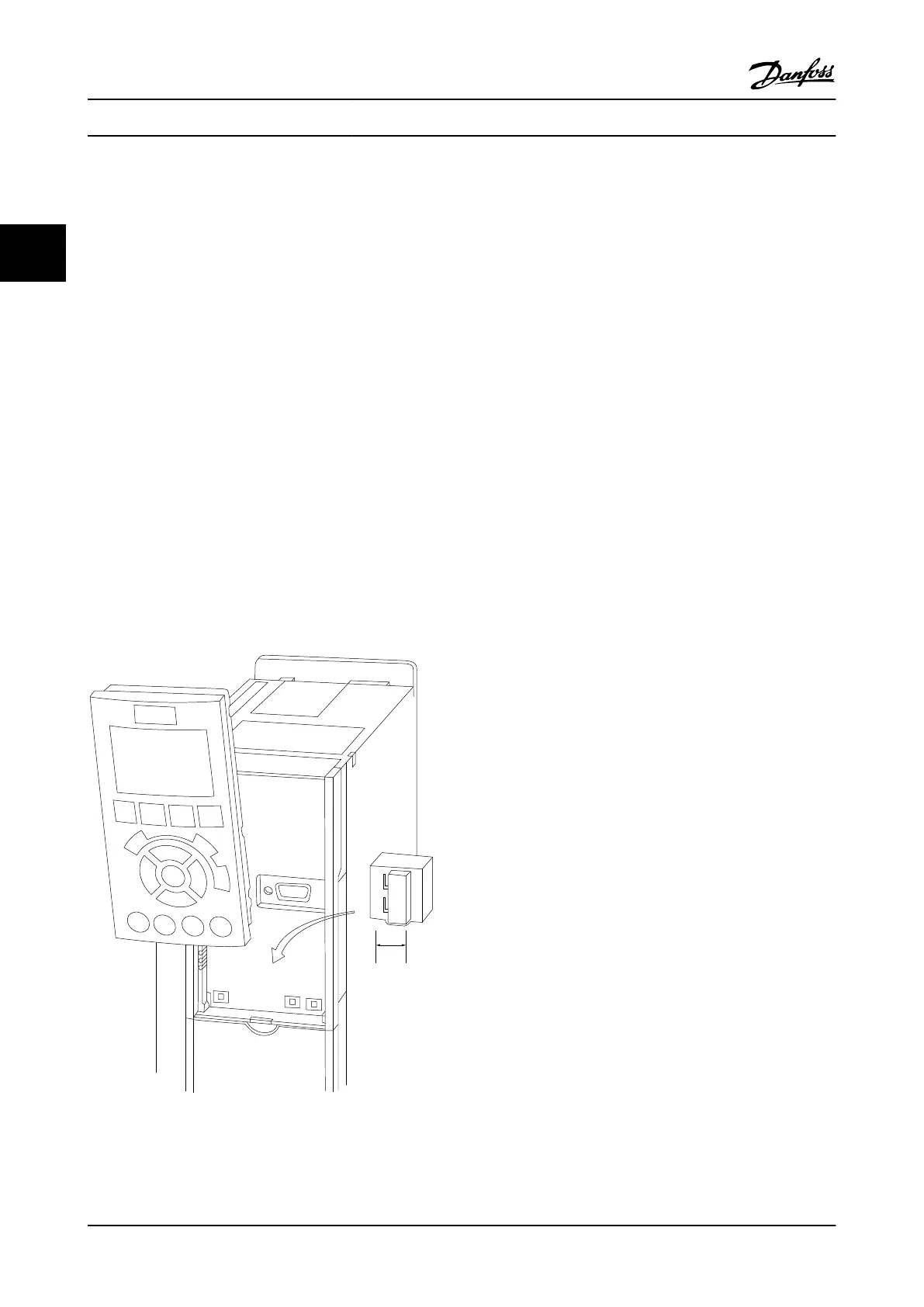

The switches are accessible when the LCP has

been removed (see Figure 2.20). Note that some

option cards available for the unit may cover

these switches and must be removed to change

switch settings. Always remove power to the unit

before removing option cards.

•

Terminal 53 default is for a speed reference signal

in open-loop set in 16-61 Terminal 53 Switch

Setting

•

Terminal 54 default is for a feedback signal in

closed-loop set in 16-63 Terminal 54 Switch Setting

130BT310.10

1

2

N O

VLT

BUS TER.

OFF-ON

A53 A54

U- I U- I

Figure 2.20 Location of Terminals 53 and 54 Switches

2.4.5.8

Mechanical Brake Control

In hoisting/lowering applications, it is necessary to be able

to control an electro-mechanical brake:

•

Control the brake using any relay output or

digital output (terminal 27 or 29).

•

Keep the output closed (voltage-free) as long as

the adjustable frequency drive is unable to

‘support’ the motor, such as when the load is too

heavy, for example.

•

Select [32] Mechanical brake control in parameter

group 5-4* Relays for applications with an electro-

mechanical brake.

•

The brake is released when the motor current

exceeds the preset value in 2-20 Release Brake

Current.

•

The brake is engaged when the output frequency

is less than the frequency set in 2-21 Activate

Brake Speed [RPM] or 2-22 Activate Brake Speed

[Hz], and only if the adjustable frequency drive

carries out a stop command.

If the adjustable frequency drive is in alarm mode or in an

overvoltage situation, the mechanical brake immediately

cuts in.

In the vertical movement, the key point is that the load

must be held, stopped, controlled (raised, lowered) in a

safe mode during the entire operation. Because the

adjustable frequency drive is not a safety device, the

crane/lift designer (OEM) must decide on the type and

number of safety devices (e.g., speed switch, emergency

brakes, etc.) to be used, in order to be able to stop the

load in case of emergency or malfunction of the system,

according to relevant national crane/lift regulations.

Installation

VLT

®

AQUA Drive

Instruction Manual

2-12 MG20M922 - VLT

®

is a registered Danfoss trademark

2

2

Loading...

Loading...