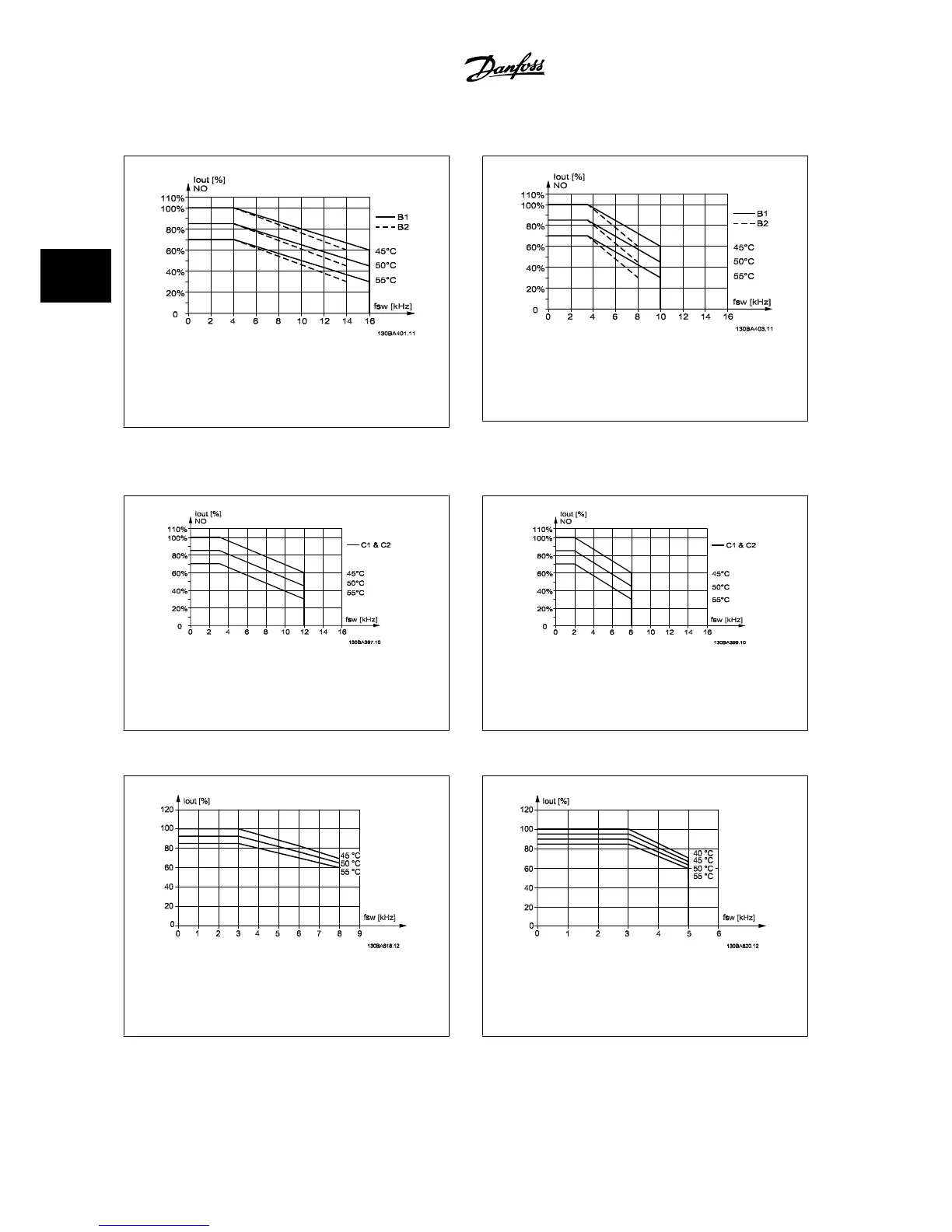

B enclosures

60 AVM - Pulse Width Modulation

Figure 3.5: Derating of I

out

for different T

AMB, MAX

for enclo-

sure B, using 60 AVM in normal torque mode (110% over

torque)

SFAVM - Stator Frequency Asyncron Vector Modulation

Figure 3.6: Derating of I

out

for different T

AMB, MAX

for enclo-

sure B, using SFAVM in normal torque mode (110% over

torque)

C enclosures

Please note: For 125 hp [90 kW] in IP55 and IP66, the max. ambient temperature is 9°F [5°C] lower.

60 AVM - Pulse Width Modulation

Figure 3.7: Derating of I

out

for different T

AMB, MAX

for enclo-

sure C, using 60 AVM in normal torque mode (110% over

torque)

SFAVM - Stator Frequency Asyncron Vector Modulation

Figure 3.8: Derating of I

out

for different T

AMB, MAX

for enclo-

sure C, using SFAVM in normal torque mode (110% over

torque)

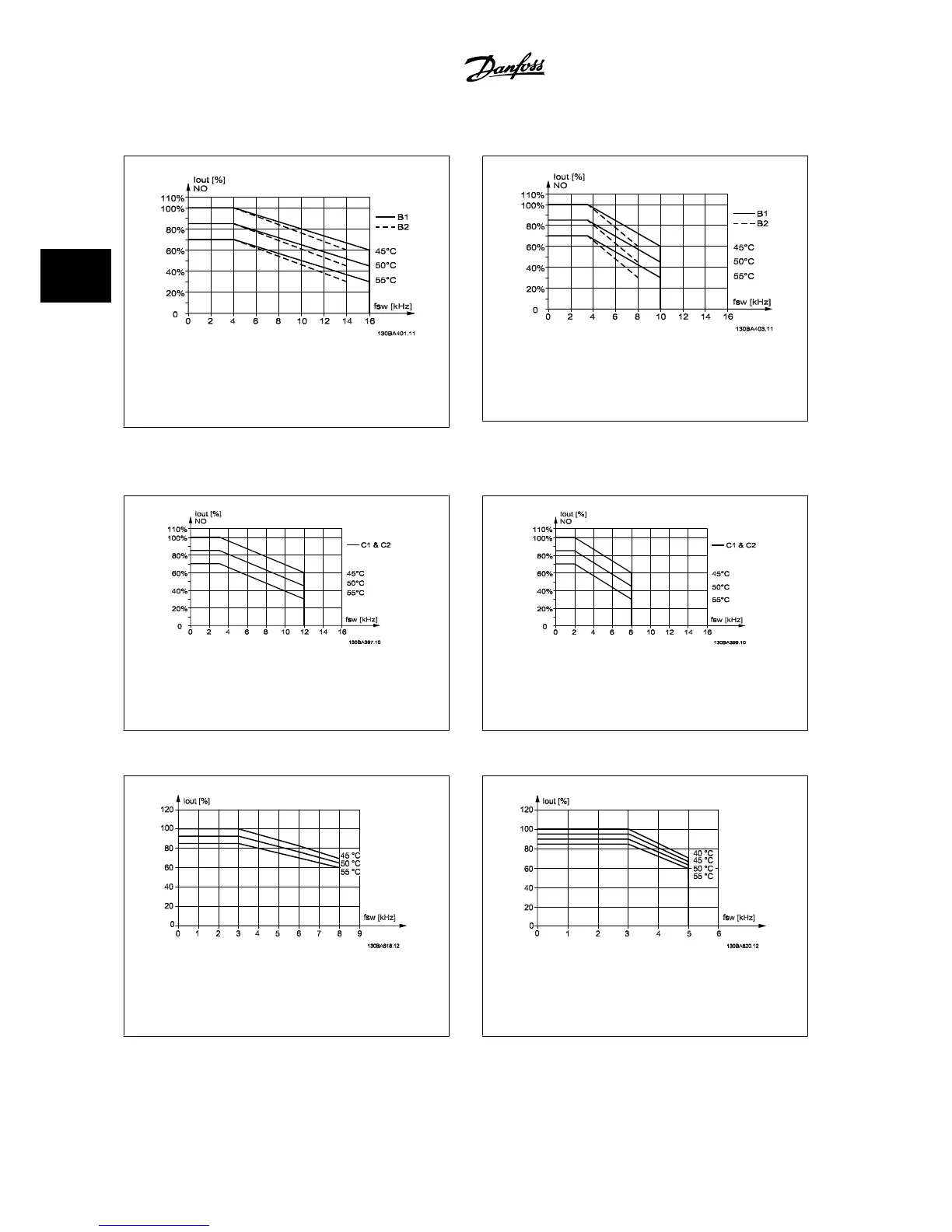

D enclosures

60 AVM - Pulse Width Modulation, 380–480 V

Figure 3.9: Derating of I

out

for different T

AMB, MAX

for enclo-

sure D at 480 V, using 60 AVM in normal torque mode

(110% over torque)

SFAVM - Stator Frequency Asyncron Vector Modulation

Figure 3.10: Derating of I

out

for different T

AMB, MAX

for en-

closure D at 480 V, using SFAVM in normal torque mode

(110% over torque)

3 VLT AQUA Selection VLT

®

AQUA Drive Design Guide

3-26

MG.20.N5.22 - VLT

®

is a registered Danfoss trademark

3

Loading...

Loading...