1-55 U/f Characteristic - U

Range: Function:

Size related* [0 - 500

V]

Enter voltage at each frequency point

to manually form a U/f characteristic

matching motor. Frequency points are

dened in parameter 1-56 U/f Charac-

teristic - F.

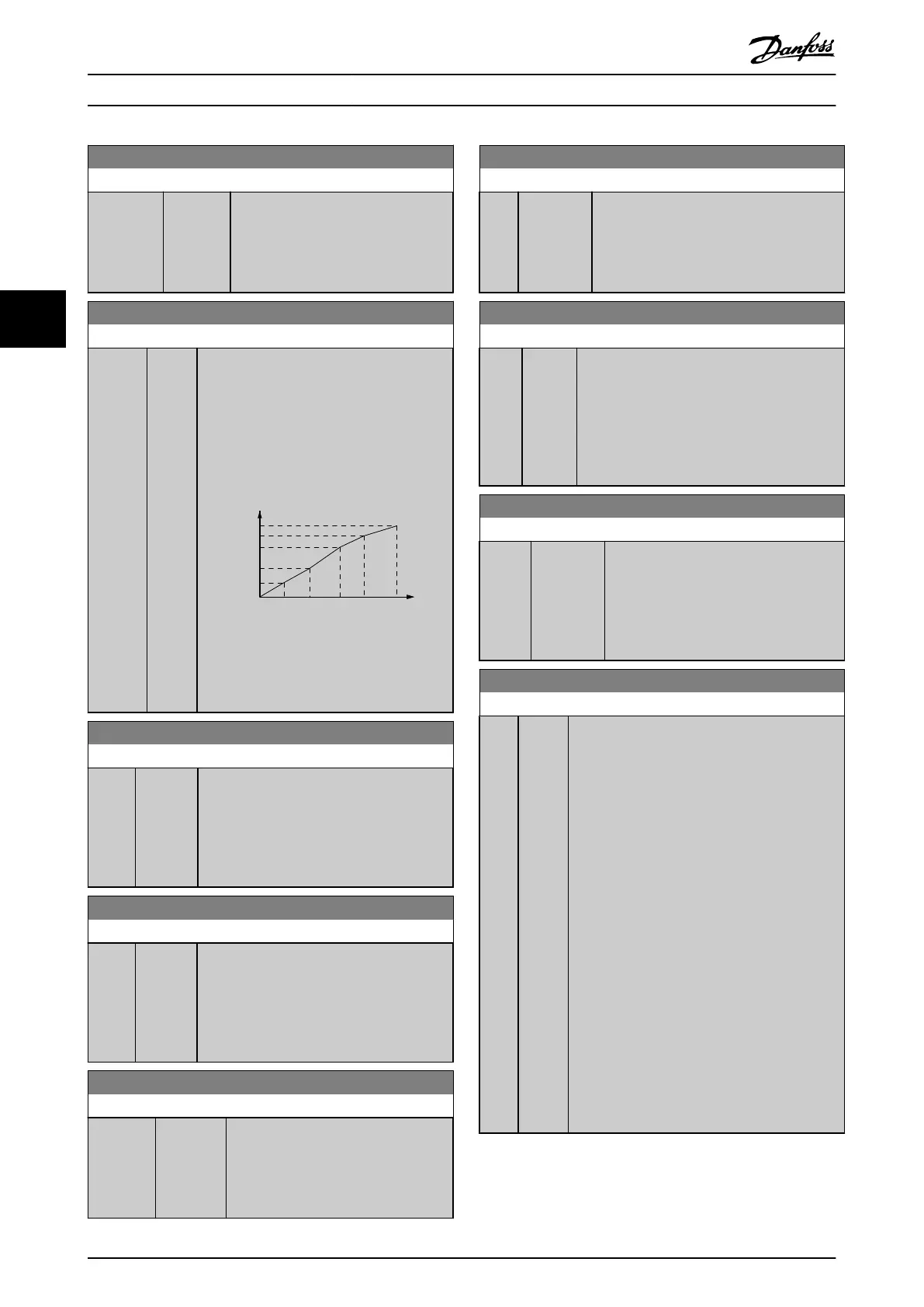

1-56 U/f Characteristic - F

Range: Function:

Size

related*

[ 0 -

400.0

Hz]

Enter frequency points to form a U/f charac-

teristic matching motor. Voltage at each point

is dened in parameter 1-55 U/f Characteristic

- U.

Make a U/f characteristic based on 6

denable voltages and frequencies, see

Illustration 4.2.

Motor Voltage

Par 1-55 [x]

Output Frequency

Par 1-56 [x]

1-55[5]

1-55[4]

1-55[3]

1-55[2]

1-55[1]

1-55[0]

1-56

[0]

1-56

[1]

1-56

[2]

1-56

[3]

1-56

[4]

1-56

[5]

130BA166.10

Illustration 4.2 Example of U/f Charac-

teristic

1-60 Low Speed Load Compensation

Range: Function:

100 %* [0 -

300 %]

Enter the low-speed voltage compensation

value in percent. This parameter is used for

optimizing the low-speed load performance.

This parameter is only active if

parameter 1-10 Motor Construction = [0]

Asynchron.

1-61 High Speed Load Compensation

Range: Function:

100 %* [0 -

300 %]

Enter the high-speed load voltage compen-

sation value in percent. This parameter is

used for optimizing the high-speed load

performance. This parameter is only active if

parameter 1-10 Motor Construction = [0]

Asynchron.

1-62 Slip Compensation

Range: Function:

Size

related*

[ -400 -

399.0 %]

Enter the % value for slip compensation

to compensate for tolerance in the

value of n

M,N

. Slip compensation is

calculated automatically, that is, based

on the nominal motor speed n

M,N

.

1-63 Slip Compensation Time Constant

Range: Function:

0.1 s* [0.05 - 5 s] Enter the slip compensation reaction speed.

A high value results in slow reaction, and a

low value results in quick reaction. If low-

frequency resonance problems occur, use a

longer time setting.

1-64 Resonance Dampening

Range: Function:

100

%*

[0 -

500 %]

Enter the resonance dampening value. Set

parameter 1-64 Resonance Dampening and

parameter 1-65 Resonance Dampening Time

Constant to help eliminate high-frequency

resonance problems. To reduce resonance

oscillation, increase the value of

parameter 1-64 Resonance Dampening.

1-65 Resonance Dampening Time Constant

Range: Function:

0.005 s* [ 0.001 -

0.05 s]

Set parameter 1-64 Resonance Dampening

and parameter 1-65 Resonance Dampening

Time Constant to help eliminate high-

frequency resonance problems. Enter the

time constant that provides the best

dampening.

1-66 Min. Current at Low Speed

Range: Function:

50 %

*

[ 0 -

120 %]

Enter the minimum motor current at low speed,

see parameter 1-53 Model Shift Frequency.

Increasing this current improves motor torque at

low speed.

Parameter 1-66 Min. Current at Low Speed is

enabled when parameter 1-00 Conguration Mode

[0] Speed open loop only. The frequency converter

runs with constant current through motor for

speeds below 10 Hz.

Parameter 4-16 Torque Limit Motor Mode and/or

parameter 4-17 Torque Limit Generator Mode

automatically adjust parameter 1-66 Min. Current

at Low Speed. The parameter with the highest

value adjusts parameter 1-66 Min. Current at Low

Speed. The current setting in parameter 1-66 Min.

Current at Low Speed is composed of the torque

generating current and the magnetizing current.

Example: Set parameter 4-16 Torque Limit Motor

Mode to 100% and set parameter 4-17 Torque

Limit Generator Mode to 60%. Parameter 1-66 Min.

Current at Low Speed automatically adjusts to

about 127%, depending on the motor size.

Parameter Descriptions

VLT

®

Midi Drive FC 280

36 Danfoss A/S © 12/2015 All rights reserved. MG07C102

44

Loading...

Loading...