7 PROFINET Acyclic Communication

PROFINET offers additional to the cyclical data communi-

cation, a cyclical communication. This feature is possible by

an IO controller (for example, PLC), as well as an IO

Supervisor (for example, PC Tool).

Cyclical communication means that data transfer takes

place all the time with a certain update rate. This is the

known function normally used for quick update of I/O

Process Data. A-cyclical communication means a one time

event, mainly used for Read/Write on parameters from

Process controllers, PC-based tools, or monitoring systems.

7.1 Features of an IO Controller System

Cyclical data exchange.

A-cyclical read/write on parameters.

The a-cyclical connection is fixed and cannot be changed

during operation.

In general an IO controller is used as Process controller,

responsible for commands, speed reference, status of the

application and so on (PLC or PC-based controller.)

The IO controller, a-cyclical connection might be used for

general parameter access in the slaves.

7.2

Features of an IO-Supervisor System

Initiate/Abort a-cyclical connection.

A-cyclical read/write on parameters.

The a-cyclical connection can be established dynamically

(Initiate) or removed (Abort) even though an IO controller

is active on the network.

The a-cyclical connection is typically used for configuration

or commissioning tools for easy access to each parameter

in any slave in the system.

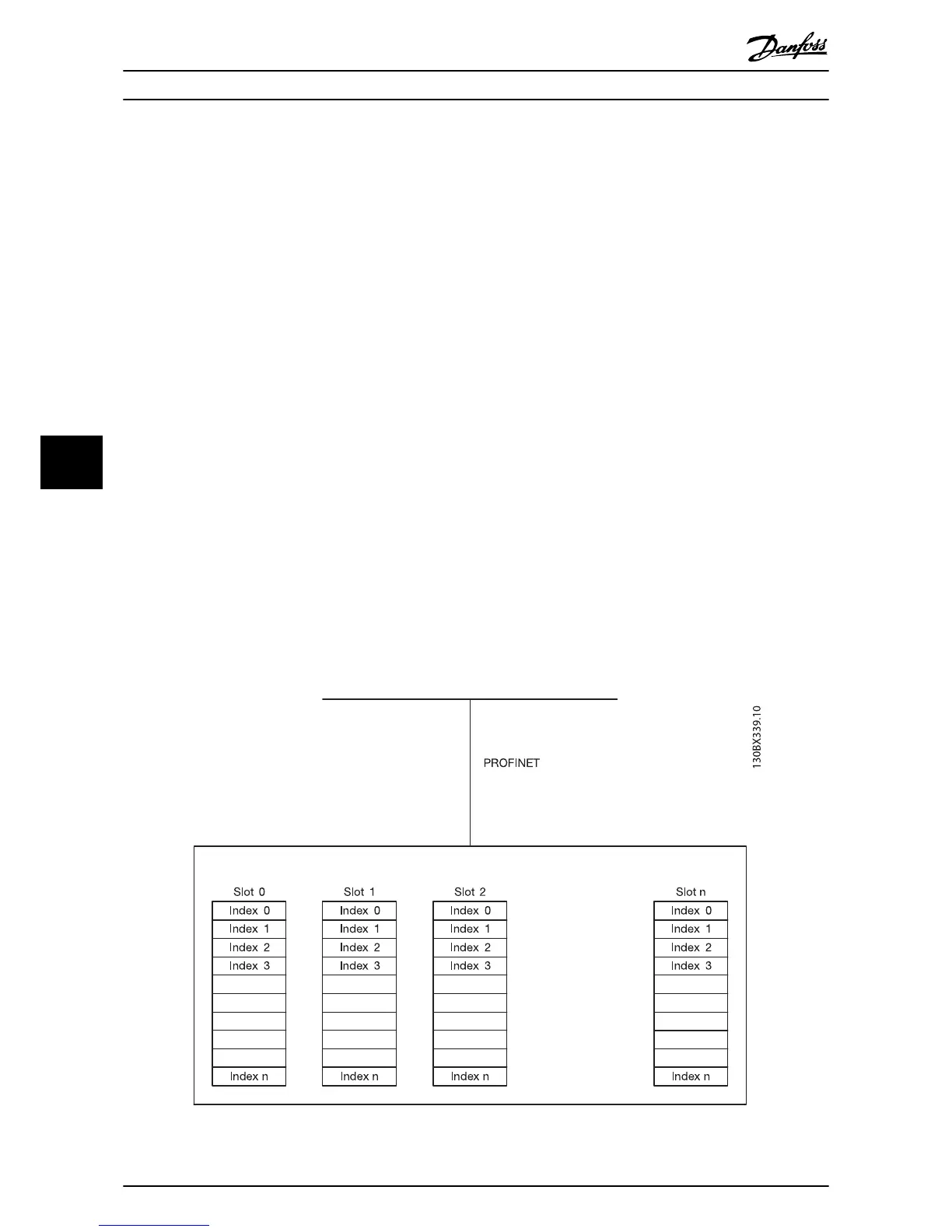

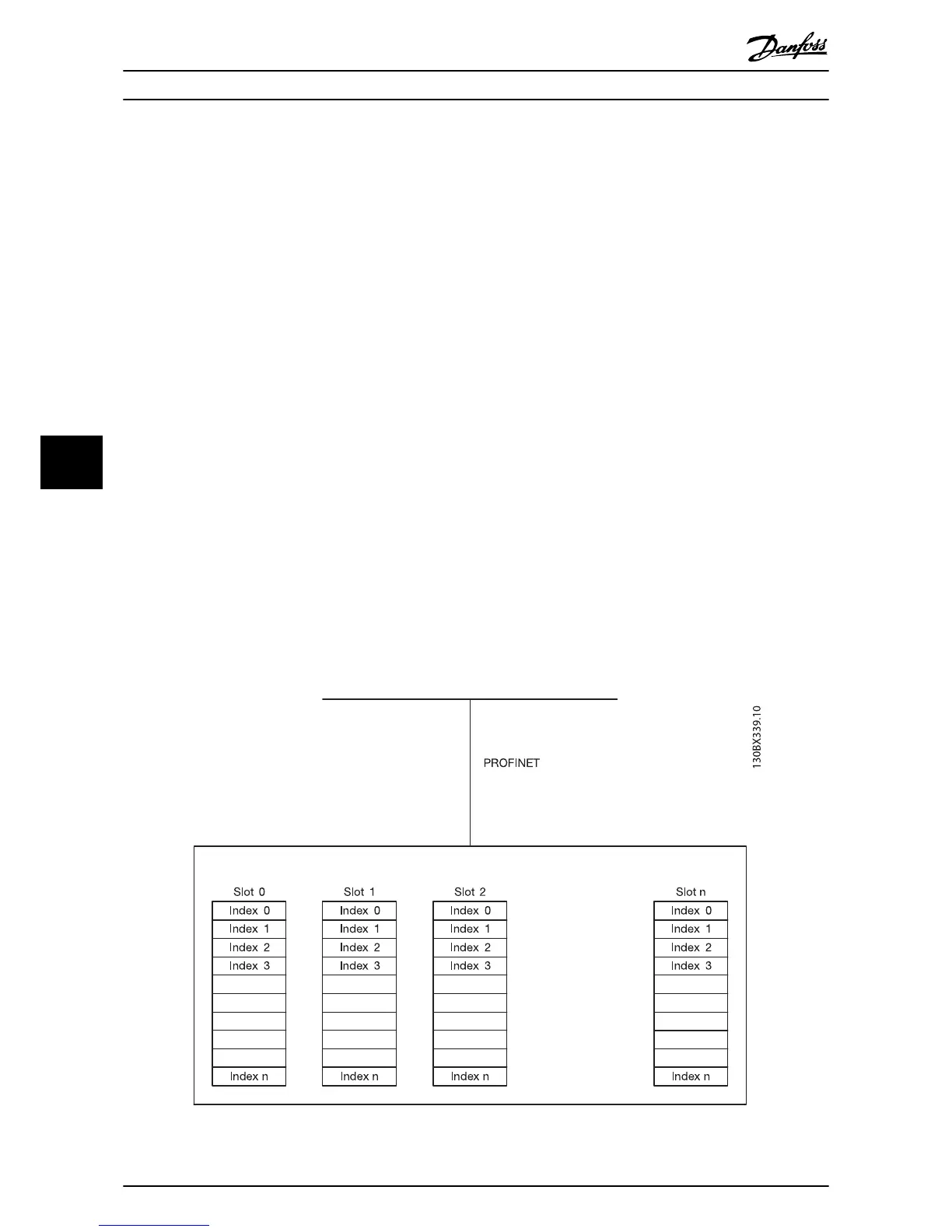

7.3 Addressing Scheme

The structure of a PROFINET IO Device is shown in

Illustration 7.1.

An IO device consists of a number of physical or virtual

slots. Slot 0 is always present, and represents the basic

unit. Each slot contains a number of data blocks addressed

by an index.

The master must address a variable in the slave as

follows: /Slave address/Slot #/Index #

Illustration 7.1 PROFINET IO Device Structure

PROFINET Acyclic Communicat... Operating Instructions

38 Danfoss A/S © Rev. 2014-02-27 All rights reserved. MG90U302

77

Loading...

Loading...