5.1 CORRECT ALIGNMENT PROCEDURE

The light curtain alignment can be effected only after having completed the mechanical installation and the

electrical connections as described above.

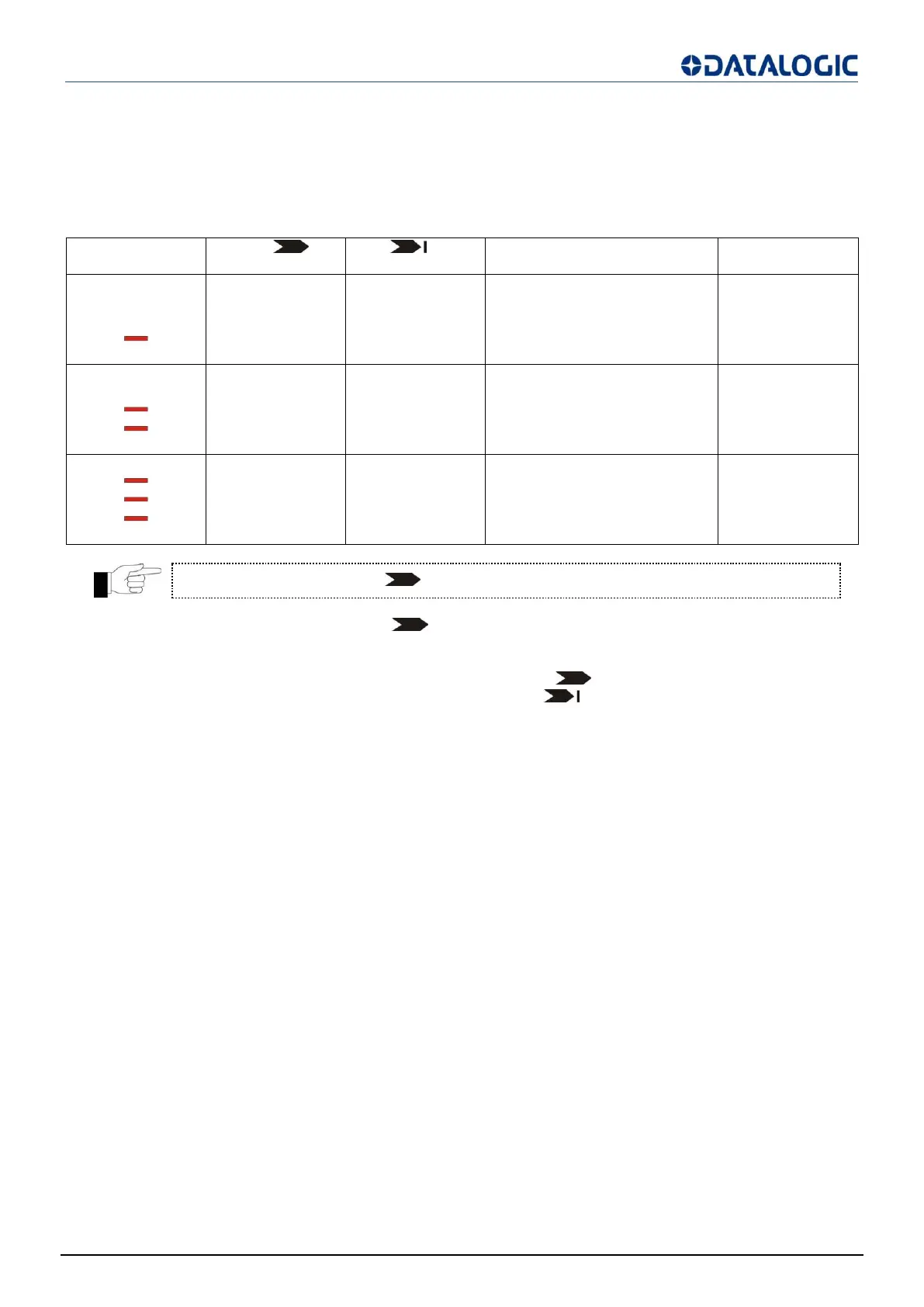

Compare alignment results with those given in the following table:

SG4-xx-xxx-OO-X:

Each beam is over the min.

operating threshold and the

number of beam

over the threshold is included

between 25 and 50%

Each beam is over the min.

operating threshold and the

number of beam

over the threshold is included

between 50 and 75%

Each beam is over the min.

operating threshold and the

number of beam

over the threshold is included

between 75 and 100%

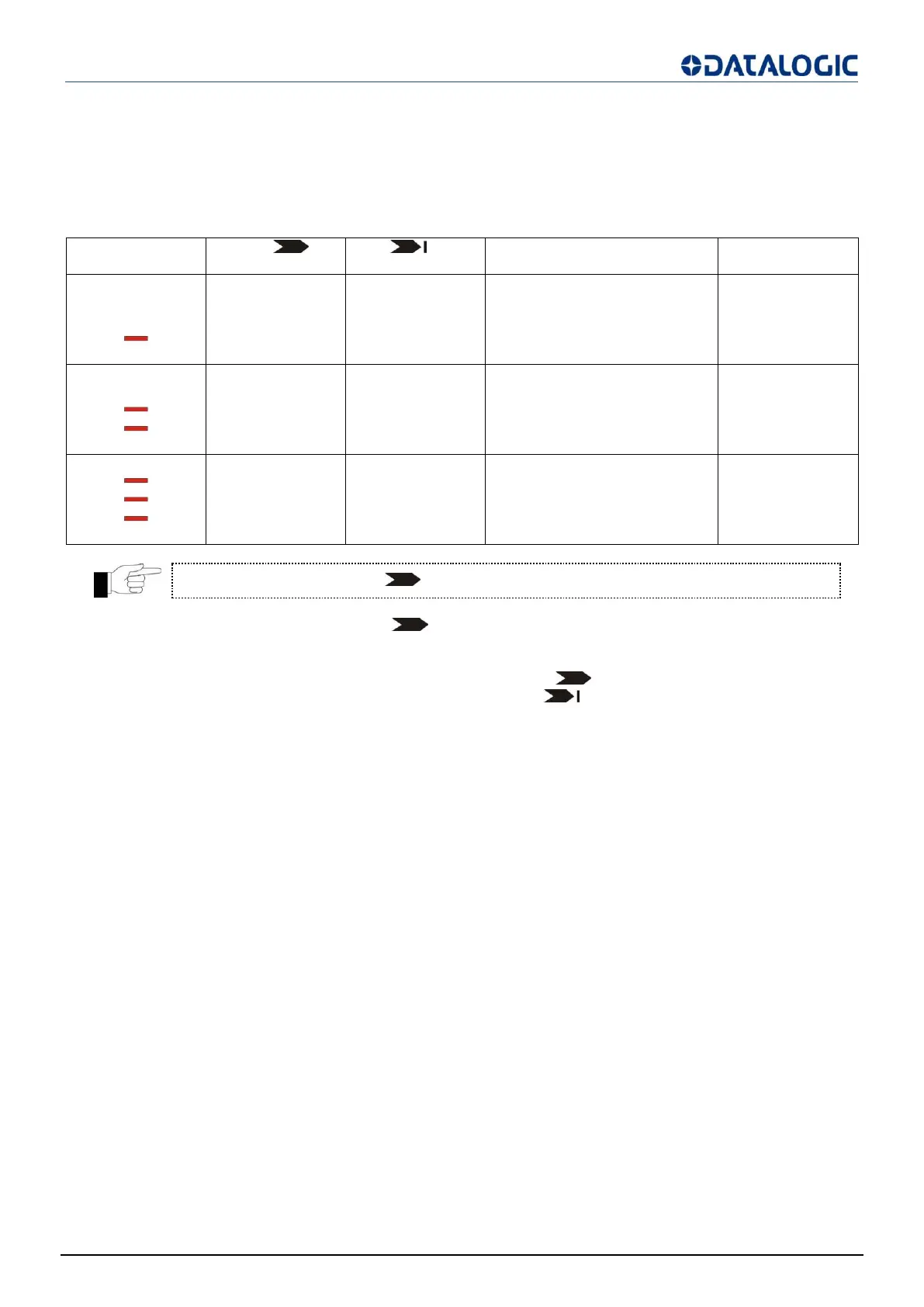

a. Delimit the area in which the green LED (( ) is steady through some micro adjustments - for the first and

then for the second unit - so to have the maximum alignment (4) and then place both units in the centre of this

area.

b. Fix the two units firmly using brackets. Verify that the green LED ( ) on the RX unit is ON and beams are

not interrupted, then verify that the red LED SAFE (BREAK) turns ON if even one single beam is

interrupted (condition where an object has been detected).This verification shall be made with the special

cylindrical “Test Piece” having a size suitable to the resolution of the device used (refer cfr.Controls after first

installation page 24.

c. Switch OFF and ON the device in normal operating mode.

The alignment level is monitored also during device standard operating mode via display (see cfr.Diagnostic

messages page 42)

Once the curtain has been aligned and correctly fastened, the display signal is useful both to check the alignment

and show a change in the environmental conditions (occurrence of dust, light disturbance and so on) via signal

level monitoring.

Ensure that the green LED ( NORMAL OP.) is steady ON.

Loading...

Loading...