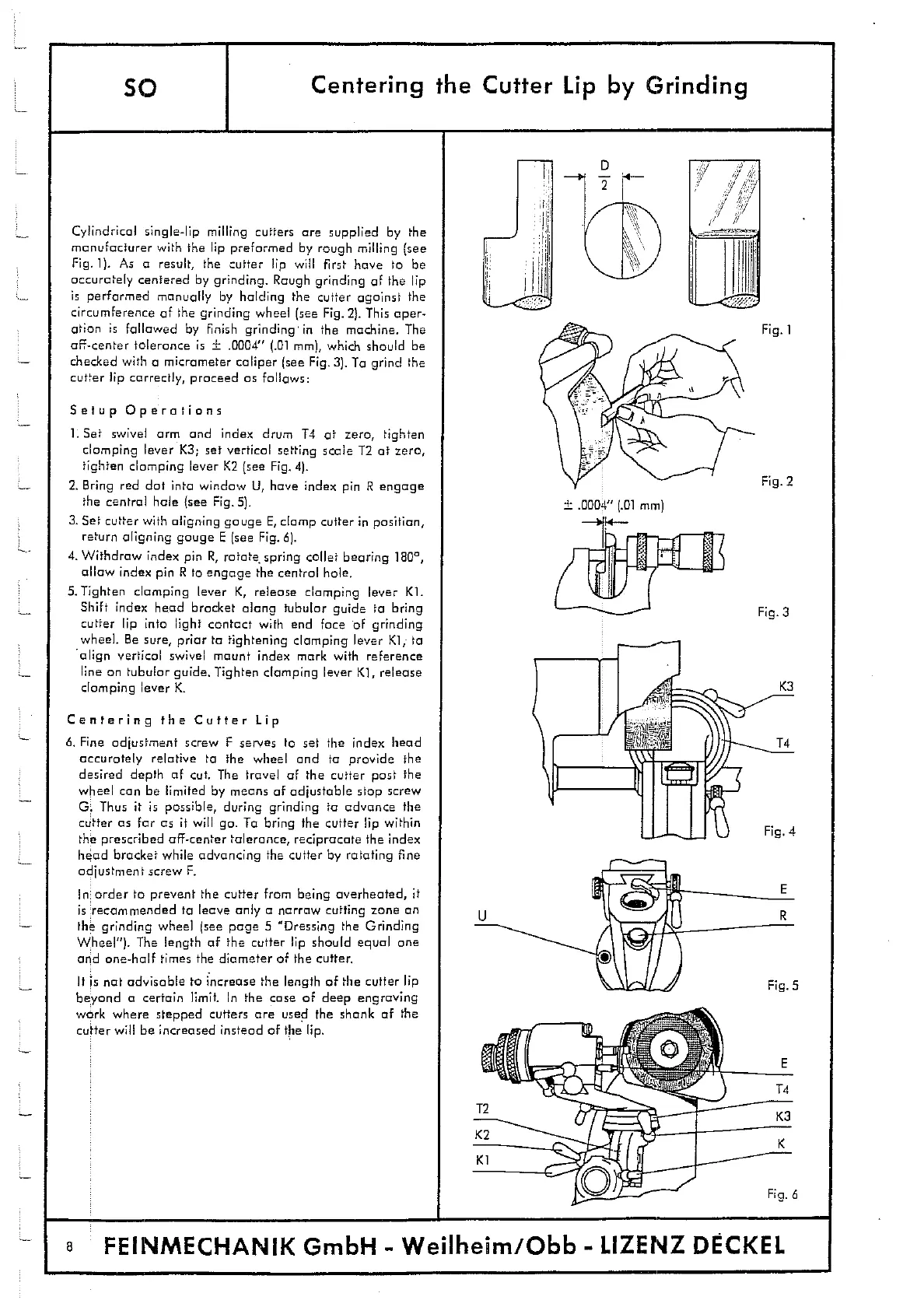

Fig. 1

Fig. 2

Fig. 3

so

Centering the Cutter Lip by Grinding

Cylindrical single-lip milling cutters are supplied by the

manufacturer with the lip preformed by rough milling (see

Fig.]). As o result, the cutter lip will first have to be

accurately centered by grinding. Rough grinding of the lip

is performed manually by holding the cutter against the

circumference of the grinding wheel (see Fig. 2). This oper-

ation is followed by finish grinding in the machine. The

off-center tolerance is ± .0004" (.01 mm), which should be

checked with a micrometer caliper (see Fig. 3). To grind the

cutter lip correctly, proceed as follows:

Setup Operations

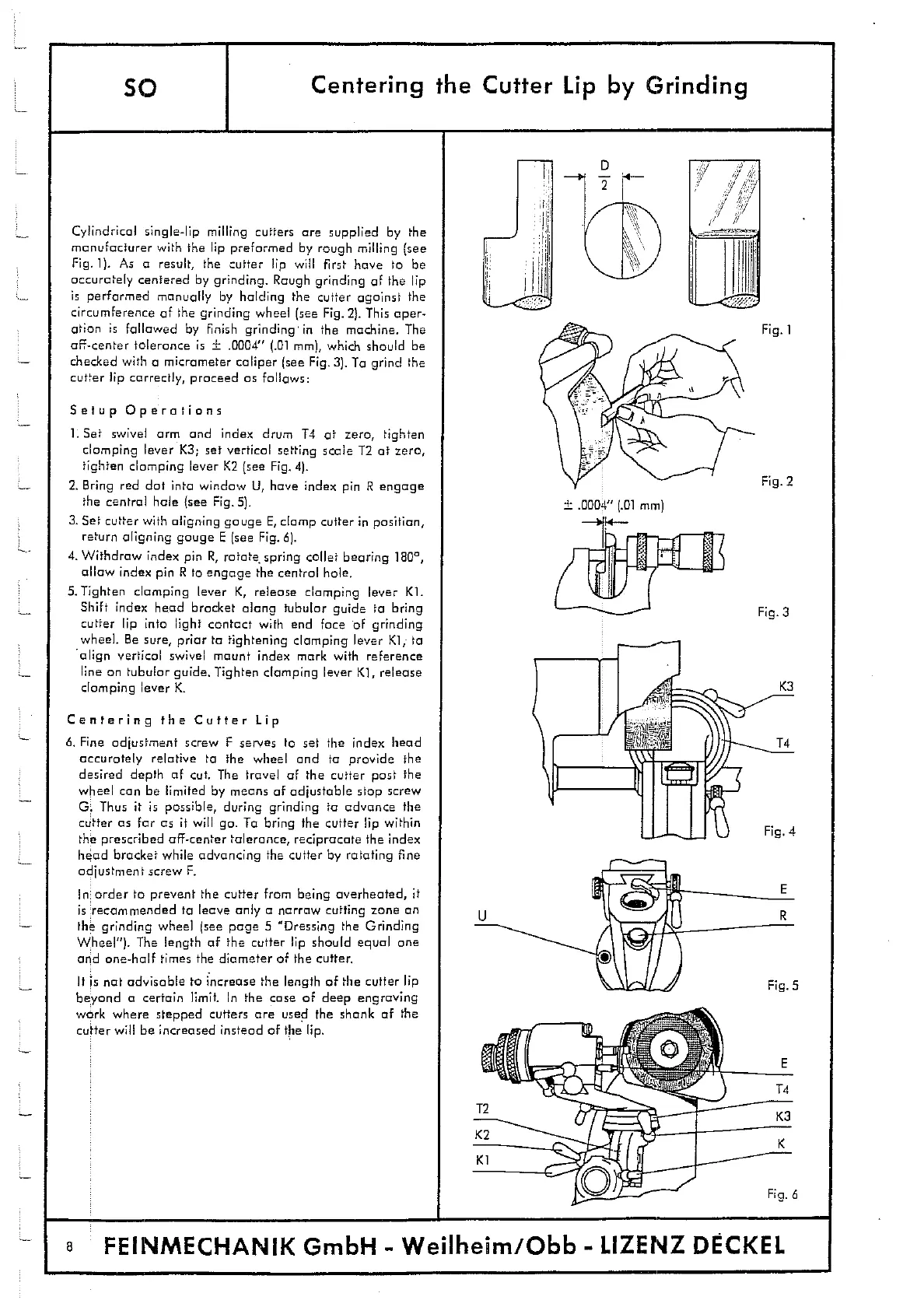

I. Set swivel arm and index drum 14 at zero, tighten

clamping lever K3; set vertical setting scale T2 at zero,

tighten clamping lever K2 (see Fig. 4).

2.

Bring red dot into window U, have index pin R engage

the central hale (see Fig. 5).

3.

Set cutter with aligning gauge E, clamp cutter in position,

return aligning gouge E (see Fig. 6).

4.

Withdraw index pin R, rotate spring collet bearing 180,

allow index pin R to engage the central hole.

5.

Tighten clamping lever K, release clamping lever KI.

Shift index head bracket along tubular guide to bring

cutter lip into light contact with end face of grinding

wheel. Be sure, prior to tightening clomping lever Ki,- to

align vertical swivel mount index mark with reference

line on tubular guide. Tighten clamping lever K], release

clamping lever K.

Centering the Cutter Lip

6.

Fine adjustment screw F serves to set the index head

accurately relative to the wheel and to provide the

desired depth of cut. The travel of the cutter past the

wheel can be limited by means of adjustable stop screw

C. Thus it is possible, during grinding to advance the

cutter as far as it will go. To bring the cutter lip within

the prescribed off-center tolerance, reciprocate the index

head bracket while advancing the cutter by rotating fine

adjustment screw F.

In order to prevent the cutter from being overheated, it

is recommended to leave only a narrow cutting zone an

the grinding wheel (see page 5 "Dressing the Grinding

Wheel"). The length of the cutter lip should equal one

and one-half times the diameter of the cutter.

It is not advisable to increase the length of the cutter lip

beyond a certain limit. In the case of deep engraving

work where stepped cutters are used the shank of the

cutter will be increased instead of the lip.

8

FEINMECHANIK

GmbH - Weilheim/Obb

- LIZENZ DECKEL

Loading...

Loading...