Cutter Profiles - Tool Angles - Cutting Speeds

so

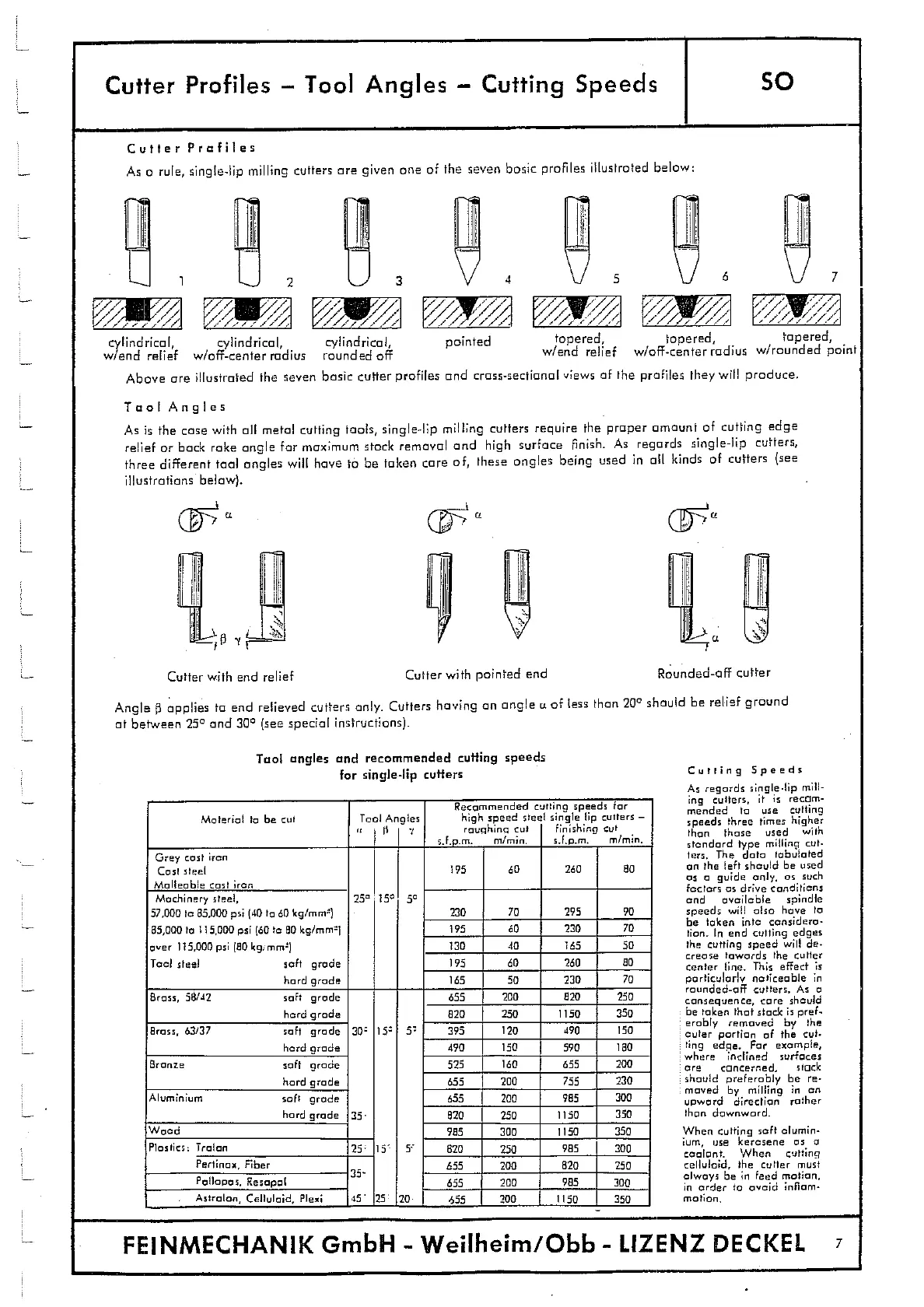

Cutter Profiles

As a rule, single-lip milling cutters are given one of the seven basic profiles illustrated below:

cylindrical

cylindrical,

cylindrical,

pointed

tapered,

tapered,

tapered,

w/end relief w/off-center radius rounded off

w/end relief w/off-center radius w/rounded pa

Above are illustrated the seven basic cutter profiles and cross-sectional views of the profiles they will produce.

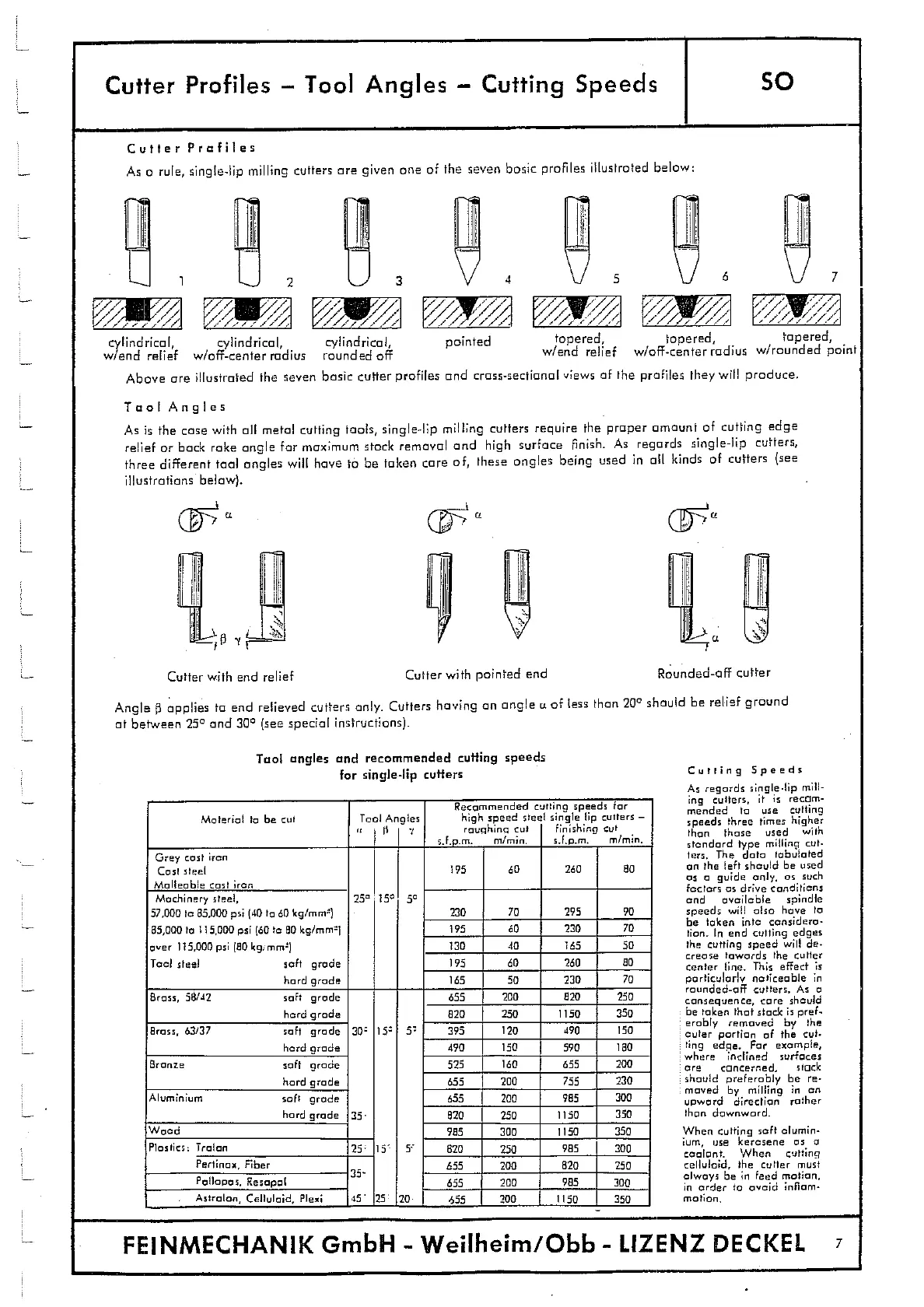

Tool Angles

As is the case with all metal cutting tools, single-lip milling cutters require the proper amount of cutting edge

relief or bock rake angle for maximum stock removal and high surface Finish. As regards single-lip cutters,

three different tool angles will have to be taken care of, these angles being used in all kinds of cutters (see

illustrations below).

a

ME

i

f

I

To q

Cutter with end relief

Cutter with pointed end

Rounded-off cutter

Angle

P

applies to end relieved cutters only. Cutters having an angle uof less than 20

0

should be relief ground

at between 25° and 30

0

(see special instructions)-

Tool angles and recommended cutting speeds

for single-lip cutters

Recommended cutting speeds for

Material to be cut

Tool Angles

high speed steel single lip cutters -

-,

rouqhinq cut

finishing cut

s.f.p.m.

rn/rain.

s..l.p.rn.

n/rain.

Grey cast iron

Cost steel

195

60

260

i

i

80

Malleable cast iron

Machinery steel,

25 15° 5°

57,000 to 85,000 psi

140

to 60 kg/mm-)

230

70

295

90

85,000 to It 5,000 psi (60 to 00 kg/mrn)

195

60

230

70

over 115.000 psi 80 kg, mm')

130

40

165

50

Tool steel

soft grade

195

60

260

80

hard grade

165

50

230

70

Brass, 5/42

soft grade - - -

655

200

820

250

hard grade

820

250

1150

350

Brass, 63137

soft grade 30 15

5

7

395

120

490

ISO

hard grade

490

ISO

590

180

Bronze

soft grade

525

160

655

200

hard grade

655

200

755

230

Aluminium

soft grade

655

200

985

300

hard grade 35

020

250

1150

350

Wood

-

985

300

1150

350

Plastics Tralon

25 15' Y

L

655

250

985

300

Pertinas, Fiber

200

820

250

Pallapos, Resopal

200

985

300

Astralon, Celluloid Plexi

45 25 20

'555

200

1150

350

Culling Speeds

As regards single-lip mill-

ing cutters, it is recom-

mended to use cutting

speeds three times higher

than those used with

standard type milling cut-

ters. The data tabulated

on the left should be used

as a guide only, as such

factors as drive conditions

and available spindle

speeds will also have to

be taken into

considera-

tion- In end culling edges

the cutting speed will de.

crease towards the cutter

center line. This effect is

particularly noticeable in

rounded-off cutters. As a

consequence, care should

be taken that stock is pref-

erably removed by the

outer portion of the cut.

ling edge. For example,

where inclined surfaces

are concerned, stock

should preferably be re-

moved by milling in on

uaword direction rather

than downward.

When cutting soft alumin-

ium, use kerosene as °

coolant. When cutting

celluloid, the cutter must

always be in feed motion,

in order to avoid nOon'

ma tion.

FEINMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

7

Loading...

Loading...