I

so

I

Dressing the Grinding Wheel

Feed screw

I

Fig. 2

flfld" h

-

i nit'

Fig. 4

Fig. 3

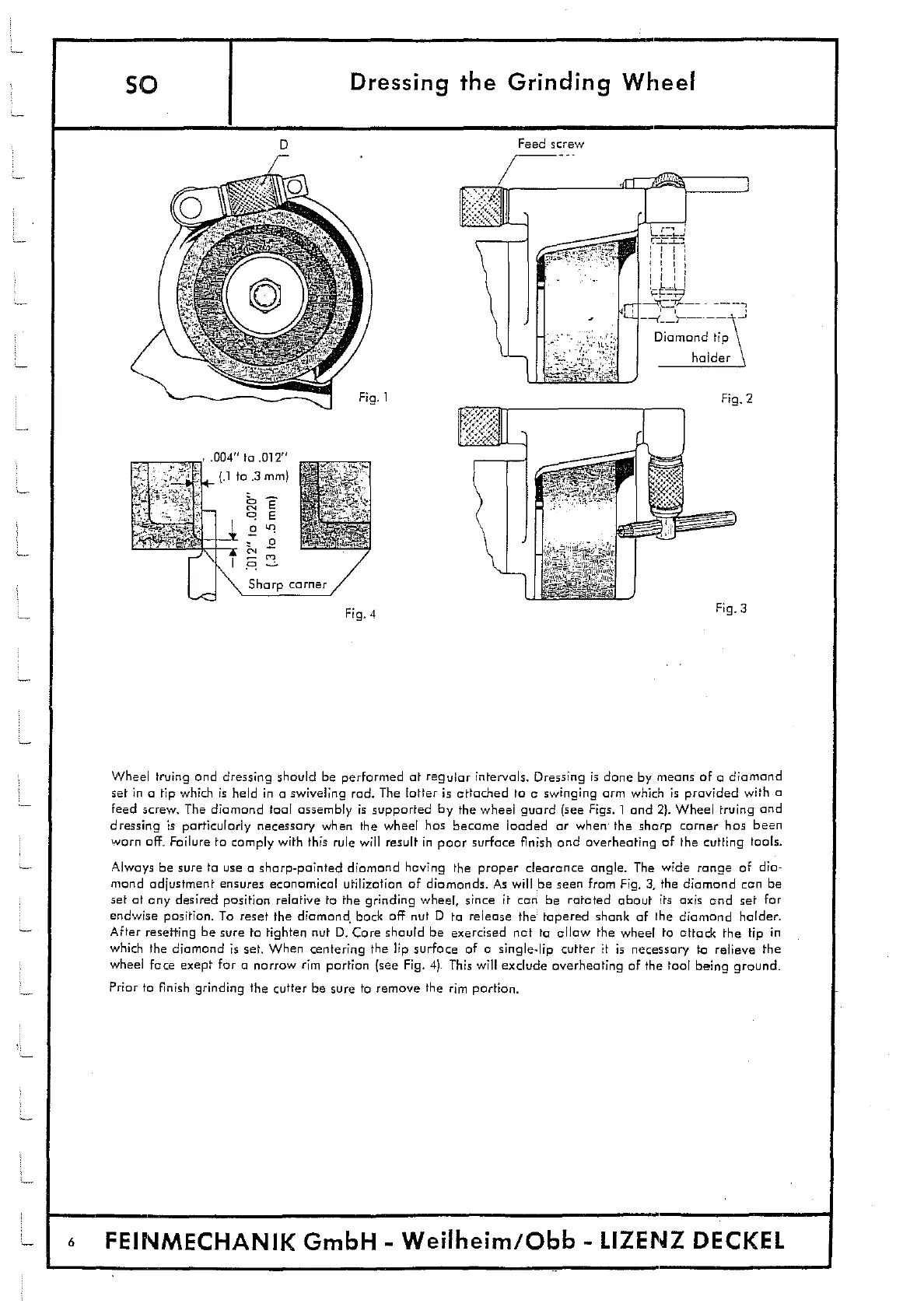

Wheel truing and dressing should be performed at regular intervals. Dressing is done by means of o diamond

set in a tip which is held in a swiveling rod. The latter is attached to a swinging arm which is provided with a

feed screw. The diamond tool assembly is supported by the wheel guard (see Figs. 1 and 2). Wheel truing and

dressing is particularly necessary when the wheel has became boded or when the sharp corner has been

worn oft Failure to comply with this rule will result in poor surface finish and overheating of the cutting tools.

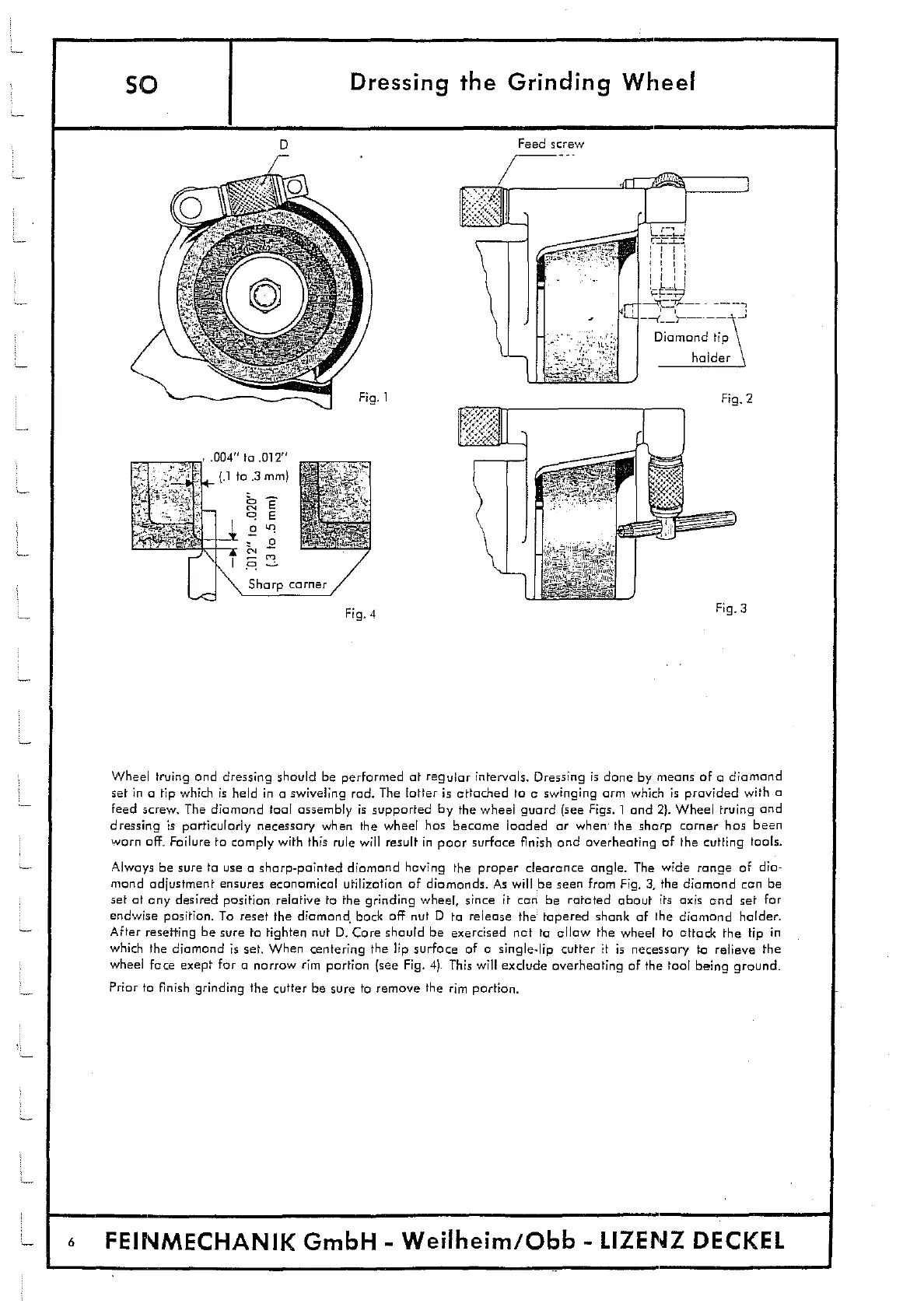

Always be sure to use a sharp-painted diamond having the proper clearance angle. The wide range of dia-

mond adjustment ensures economical utilization of diamonds. As will be seen from Fig. 3, the diamond can be

set at any desired position relative to the grinding wheel, since it can be rotated about its axis and set for

endwise position. To reset the diamond, bock off nut D to release the tapered shank of the diamond holder.

After resetting be sure to tighten nut D. Core should be exercised not to allow the wheel to attack the tip in

which the diamond is set. When centering the lip surface of a single-lip cutter it is necessary to relieve the

wheel face exept for a narrow rim portion (see Fig. 4). This will exclude overheating of the tool being ground.

Prior to Finish grinding the cutter be sure to remove the rim portion.

I

6

FEINMECHANIK GmbH - Weilheim/Qbb - LIZENZ DECKEL

Loading...

Loading...