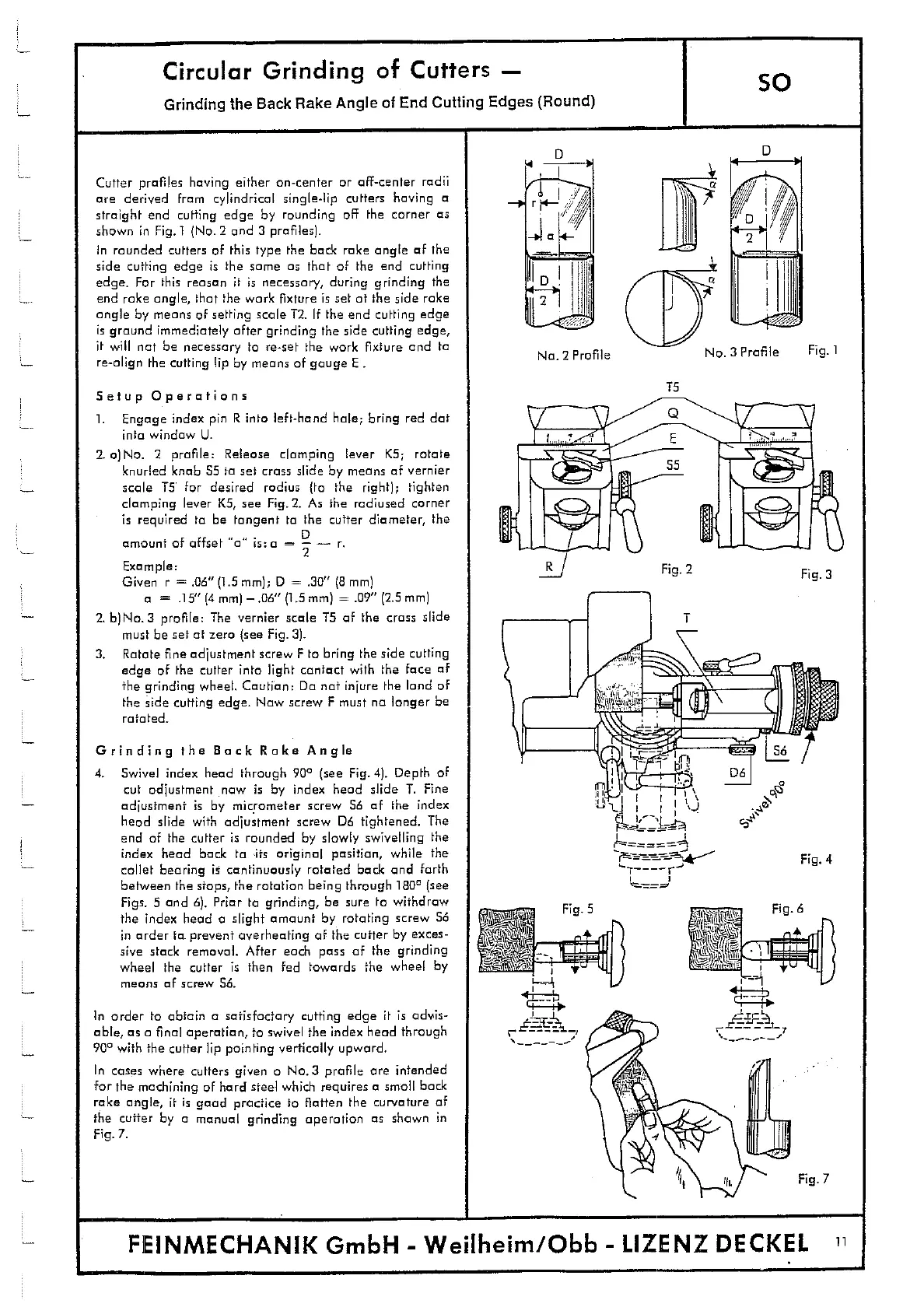

No. 2 Profile

No. 3 Profile

Fig. 1

15

Fig. S

Circular Grinding of Cutters -

so

Grinding the Back Rake Angle of End Cutting Edges (Round)

Cutter profiles having either on-center or off-center radii

are derived from cylindrical single-lip cutters having a

straight end cutting edge by rounding off the corner as

shown in Fig. 1 (No.2 and 3 profiles).

In rounded cutters of this type the bock rake angle of the

side cutting edge is the some as that of the end cutting

edge. For this reason it is necessary, during grinding the

end rake angle, that the work fixture is set at the side rake

angle by means of setting scale 12. If the end cutting edge

is ground immediately after grinding the side cutting edge,

it will not be necessary to re-set the work fixture and to

re-align the cutting lip by means of gauge E -

Setup Operations

1.

Engage index pin R into left-hand hale; bring red dot

into window U.

2.

a)No. 2 profile: Release clamping lever KS; rotate

knurled knob 55 to set crass slide by means of vernier

scale T5 for desired radius (to the right); tighten

clamping lever K5, see Fig. 2. As the radiused corner

is required to be tangent to the cutter diameter, the

amount of offset "a is:a =

Example:

Given r = .06" (1.5 mm); D = .30" (8 mm)

o = .15" (4 mm) —.06" (1.5 mm) = .09" (2.5 mm)

2. b)No. 3 profile: The vernier scale 15 of the crass slide

must be set at zero (see Fig. 3).

3.

Rotate fine adjustment screw F to bring the side cutting

edge of the cutter into light contact with the face of

the grinding wheel. Caution: Do not injure the land of

the hide cuffing edge. Now screw F must no longer be

rotated.

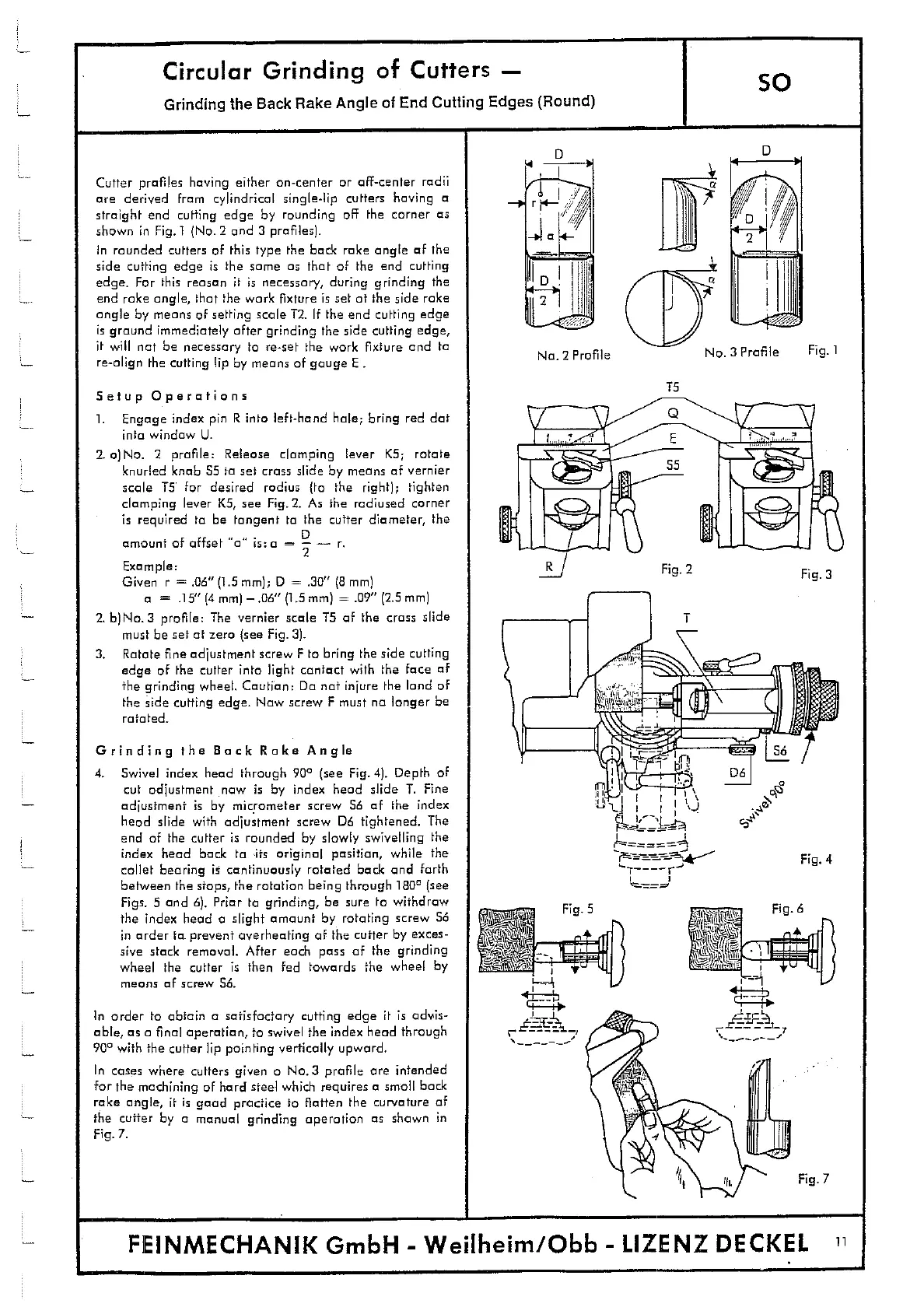

Grinding the Back Rake Angle

4.

Swivel index head through

90

(see Fig. 4). Depth of

cut adjustment now is by index head slide T. Fine

adjustment is by micrometer screw S6 of the index

head slide with adjustment screw D6 tightened. The

end of the cutter is rounded by slowly swivelling the

index head back to its original position, while the

collet bearing is continuously rotated bock and forth

between the stops, the rotation being through

1800

(see

Figs. 5 and 6). Friar to grinding, be sure to withdraw

the index head a slight amount by rotating screw 56

in order to prevent overheating of the cutter by exces-

sive stock removal. After each pass of the grinding

wheel the cutter is then fed towards the wheel by

means of screw 56.

In order to obtain a satisfactory cutting edge it is advis-

able, as a final operation, to swivel the index head through

90

0

with the cutter lip pointing vertically upward.

In cases where cutters given a No.3 profile are intended

for the machining of hard steel which requires a small bath

rake angle, it is good practice to flatten the curvature of

the cutter by a manual grinding operation as shown in

Fig. 7.

F8NMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

11

Loading...

Loading...