Grinding Tapered Cutters -

so

C. Grinding the Back Rake Angle of Side and End Cutting Edges (Round)

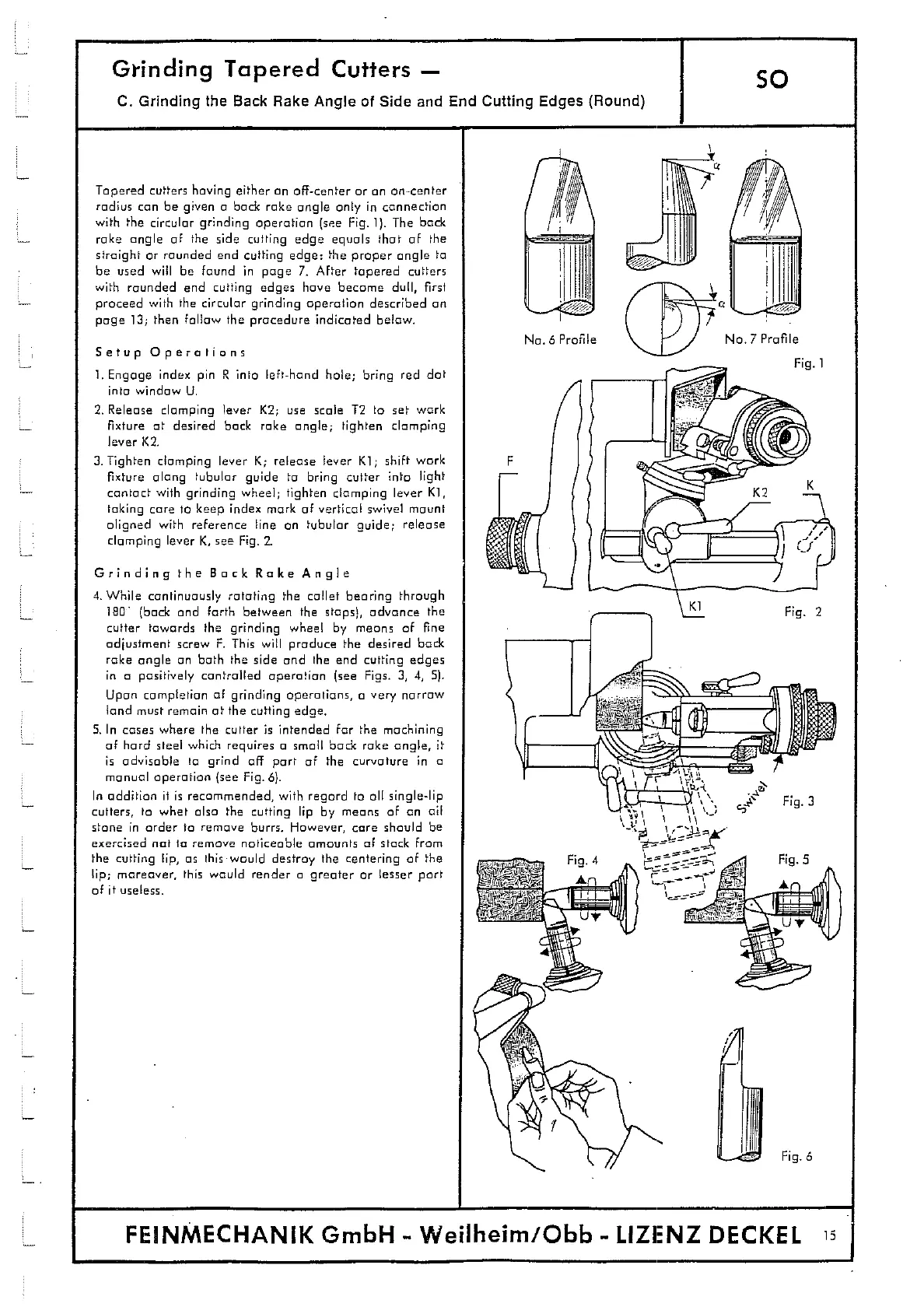

Tapered cutters having either an off-center or an on-center

radius can be given a back rake angle only in connection

with the circular grinding operation (see Fig. 1). The back

rake angle of the side cutting edge equals that of the

straight or rounded end cutting edge: the proper angle to

be used will be found in page 7. After tapered cutters

with rounded end cutting edges have become dull, first

proceed with the circular grinding operation described an

page 13; then fallow the procedure indicated below.

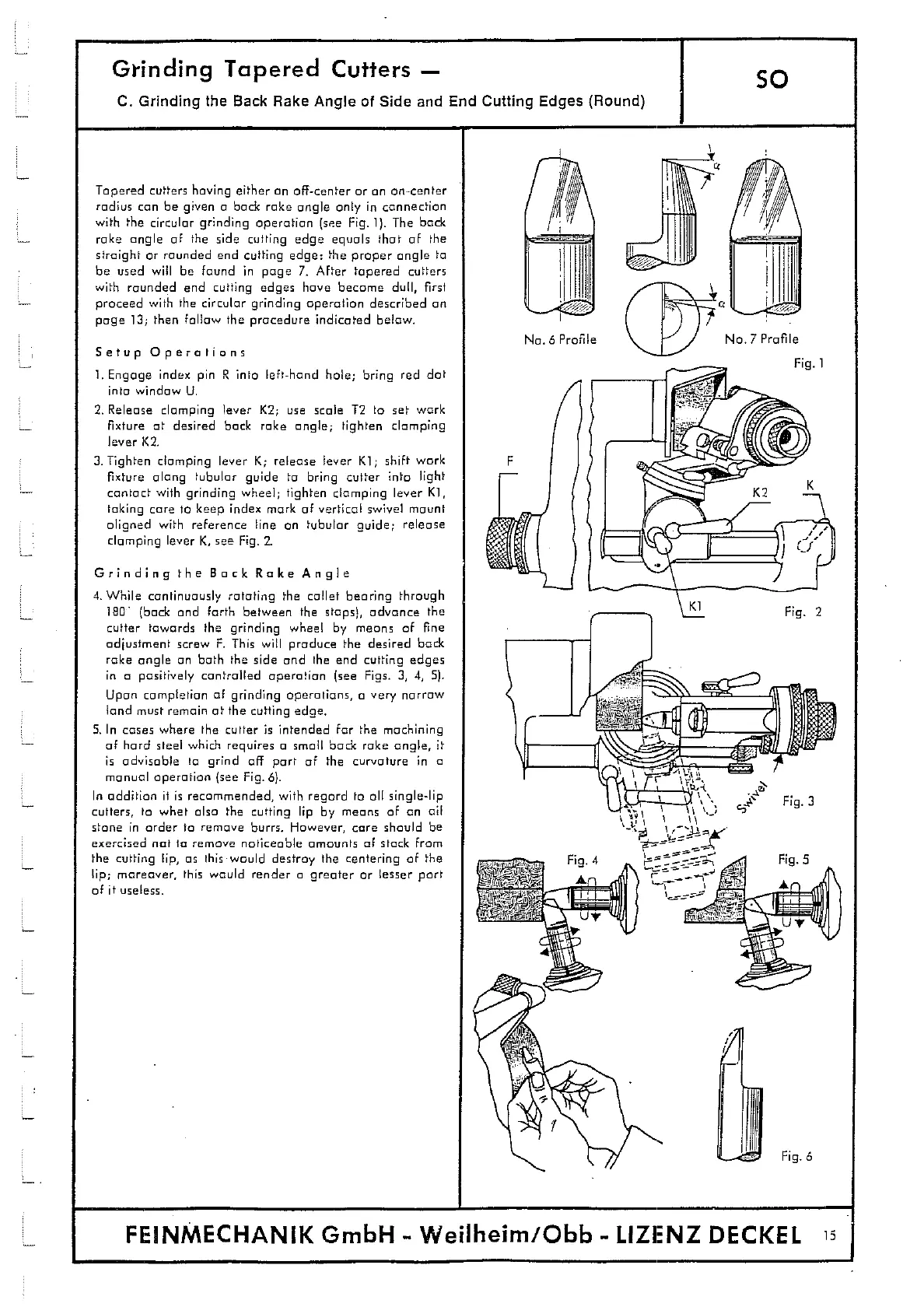

Setup Operations

1.

Engage index pin R into left-hand hole; bring red dot

into window U.

2.

Release clamping lever K2; use scale T2 to set work

Fixture at desired bock rake angle

;

tighten clamping

lever 1(2.

3.

Tighten clomping lever K; release lever K1 ; shift work

Fixture along tubular guide to bring cutter into light

contact with grinding wheel; tighten clomping lever K1

taking core to keep index mark of vertical swivel mount

aligned with reference line on tubular guide; release

clamping lever K, see Fig. 2.

Grinding the Back Rake Angle

4.

While continuously rotating the collet bearing through

180 (bock and forth between the stops), advance the

cutter towards the grinding wheel by means of Fine

adjustment screw F. This will produce the desired bock

rake angle on both the side and the end cutting edges

in o positively controlled operation (see Figs. 3, 4, 5).

Upon completion of grinding operations, o very narrow

land must remain at the cutting edge.

5.

In cases where the cutter is intended for the machining

of hard steel which requires a small bock rake angle, it

is advisable to grind off port of the curvature in o

manual operation (see Fig. 6).

In addition it is recommended, with regard to all single-lip

cutters, to whet also the cutting lip by means of on oil

stone in order to remove burrs. However, core should be

exercised not to remove noticeable amounts of stock from

the cutting lip, as this would destroy the centering of the

lip; moreover, this would render a greater or lesser port

of it useless.

No.6 Profile

No.7 Profile

F;,-, I

- I

F8NMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

15

Loading...

Loading...