Cg 3

1.4

Circular Grinding of Cutters

--

Grinding the Back Rake Angle of End Cutting Edges (Straight)

so

4:.

/1

'I

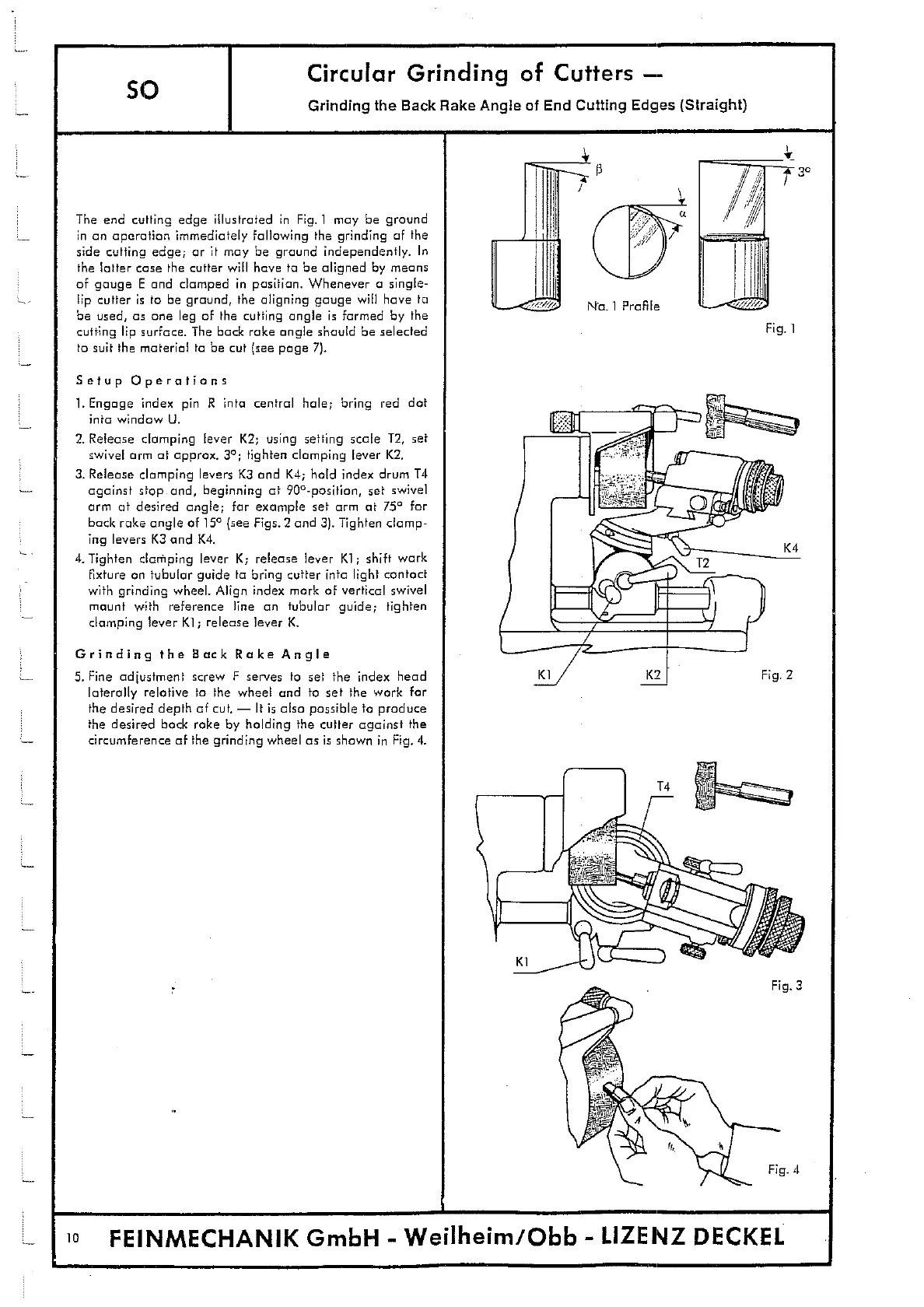

Nta 1 Profile

Fig. 1

The end cutting edge illustrated in Fig. 1 may be ground

in an operation immediately following the grinding of the

side cutting edge; or it may be ground independently. In

the latter case the cutter will have to be aligned by means

of gouge F and clomped in position. Whenever a single-

lip cutter is to be ground, the aligning gauge will have to

be used, as one leg of the cutting angle is formed by the

cutting lip surface. The back rake angle should be selected

to suit the material to be cut (see page 7).

Setup Operations

1.

Engage index pin R into central hale; bring red dot

into window U.

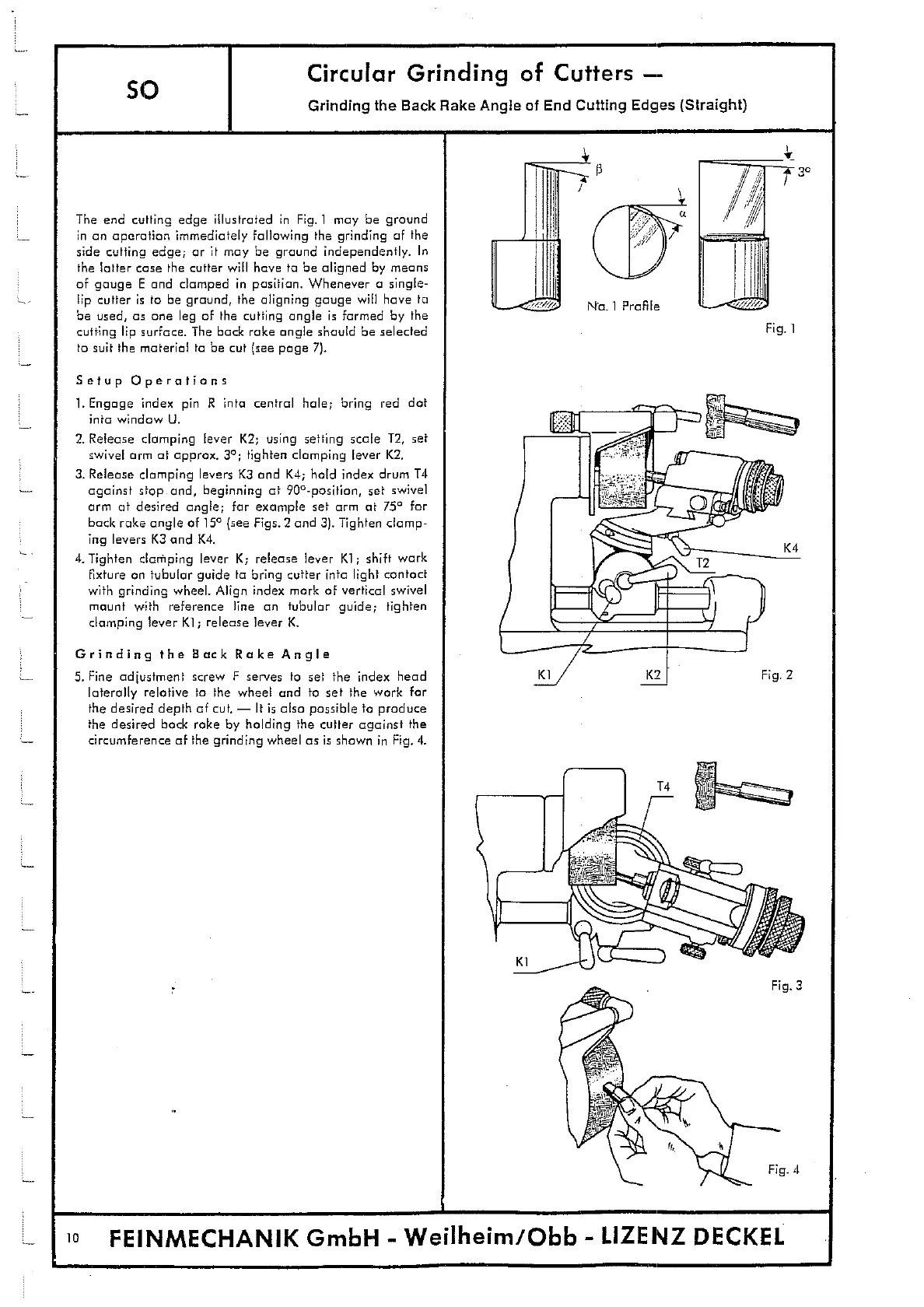

2.

Release clomping lever K2; using setting scale T2, set

swivel arm at approx. 3

0

; tighten clamping lever K2.

3.

Release clamping levers K3 and K4; hold index drum T4

against stop and, beginning at

90a.positian,

set swivel

arm at desired angle; for example set arm at 75

0

for

back rake angle of 15

0

(see Figs. 2 and 3). Tighten clomp-

ing levers K3 and K4.

4.

Tighten clamping lever K; release lever K1; shift work

Fixture an tubular guide to bring cutter into light contact

with grinding wheel. Align index mark of vertical swivel

mount with reference line an tubular guide; tighten

clamping lever K1 ; release lever K.

Grinding the Back Rake Angle

5.

Fine adjustment screw F serves to set the index head

laterally relative to the wheel and to set the work for

the desired depth of cut. - It is also possible to produce

the desired bock rake by holding the cutter against the

circumference of the grinding wheel as is shown in Fig. 4.

110

FEINMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

Loading...

Loading...