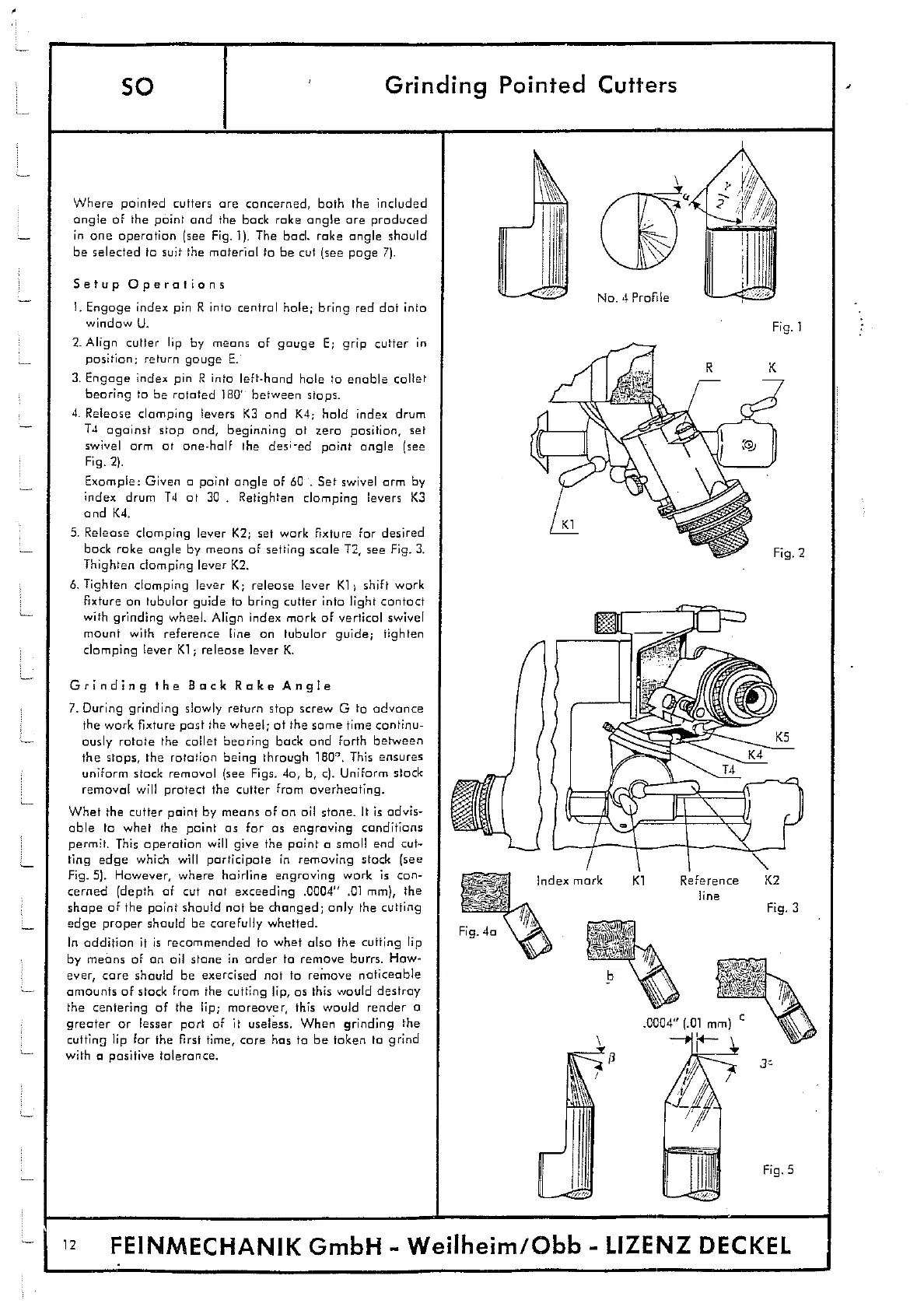

Fig. 1

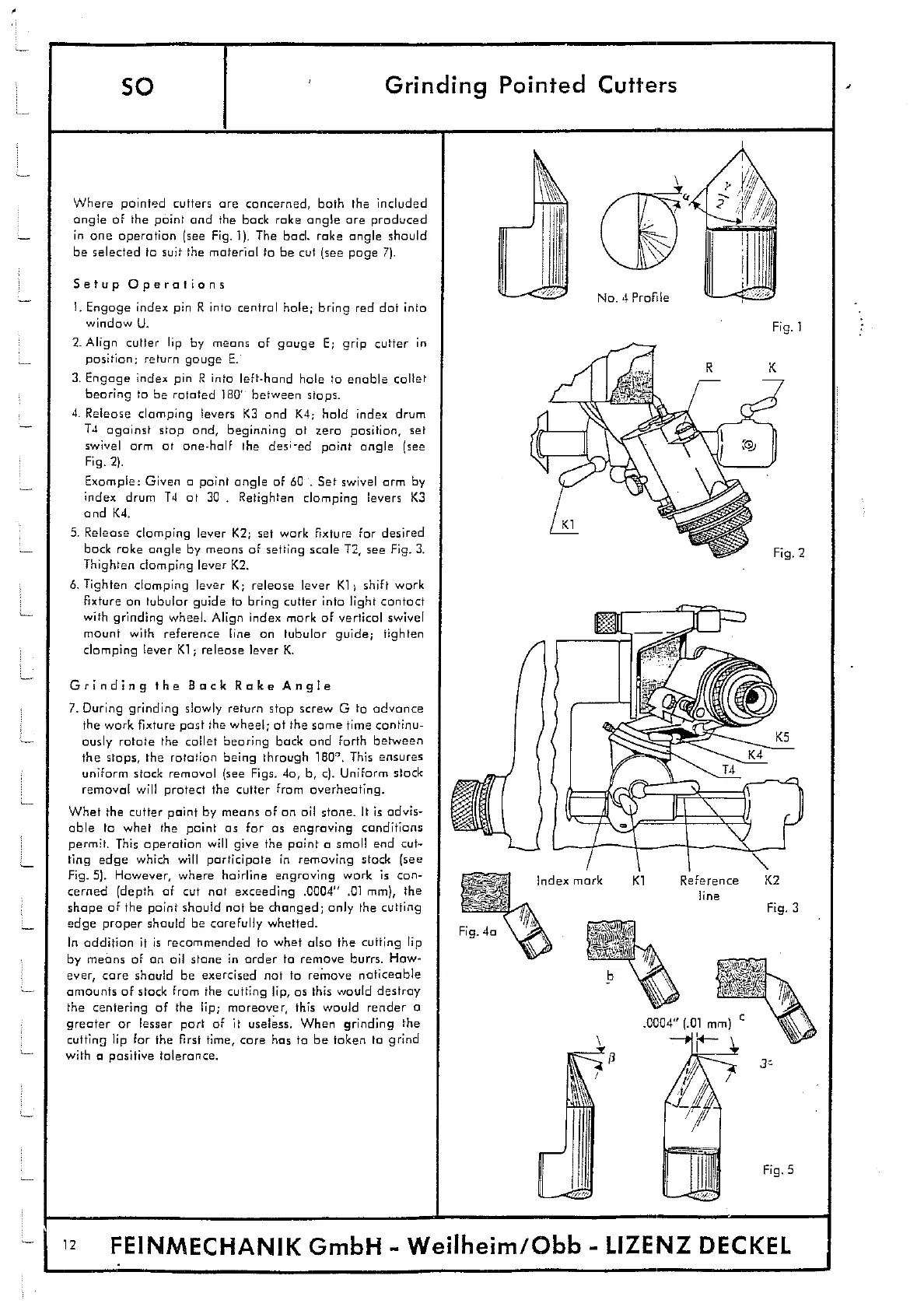

g. 2

ex

F!. 40

mark

K1

Fig. 3

.0004" (.01 mm) c

r

f3

/

Reference

K2

line

3C

so

Grinding Pointed Cutters

Where pointed cutters are concerned, both the included

angle of the point and the bock rake angle are produced

in one operation (see Fig. 1). The bad, rake angle should

be selected to suit the material to be cut (see page 7).

Setup Operations

I. Engage index pin R into central hole; bring red dot into

window U.

2.

Align cutler lip by means of gouge F; grip cutter in

position

;

return gouge E.

3.

Engage index pin R into left-hand hole to enable collet

bearing to be rotated 180 between stops.

4.

Release clomping levers K3 and K4

;

hold index drum

T4 against stop and, beginning at zero position, set

swivel arm at one-half the desHed point angle (see

Fig. 2).

Example: Given o point angle of 60 . Set swivel arm by

index drum 14 at 30 . Retighten clomping levers K3

and K4.

5.

Release clomping lever K2; set work fixture for desired

bock rake angle by means of setting scale T2, see Fig. 3.

Thighten clomping lever <2.

6.

Tighten clomping lever K; release lever K1; shift work

Fixture on tubular guide to bring cutter into light contact

with grinding wheel. Align index mark of vertical swivel

mount with reference line on tubular guide; tighten

clomping lever K1

;

release lever K.

Grinding the Back Rake Angle

7.

During grinding slowly return stop screw G to advance

the work fixture post the wheel; at the some time continu-

ously rotate the collet bearing bock and forth between

the stops, the rotation being through 180'. This ensures

uniform stock removal (see Figs. 4o, b, c). Uniform stock

removal will protect the cutter from overheating.

Whet the cutter point by means of on oil stone. It is advis-

able to whet the paint as for as engraving conditions

permit. This operation will give the point a small end cut-

ting edge which will participate in removing stock (see

Fig. 5). However, where hairline engraving work is con-

cerned (depth of cut not exceeding .0004" .01 mm), the

shape of the point should not be changed; only the cutting

edge proper should be carefully whetted.

In addition it is recommended to whet also the cutting lip

by means of on oil stone in order to remove burrs. How-

ever, core should be exercised not to remove noticeable

amounts of stock from the cutting lip, as this would destroy

the centering of the lip; moreover, this would render o

greater or lesser port of it useless. When grinding the

cutting lip for the first time, core has to be token to grind

with a positive tolerance.

A

Fig. 5

FEINMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

Loading...

Loading...