Fig. 3

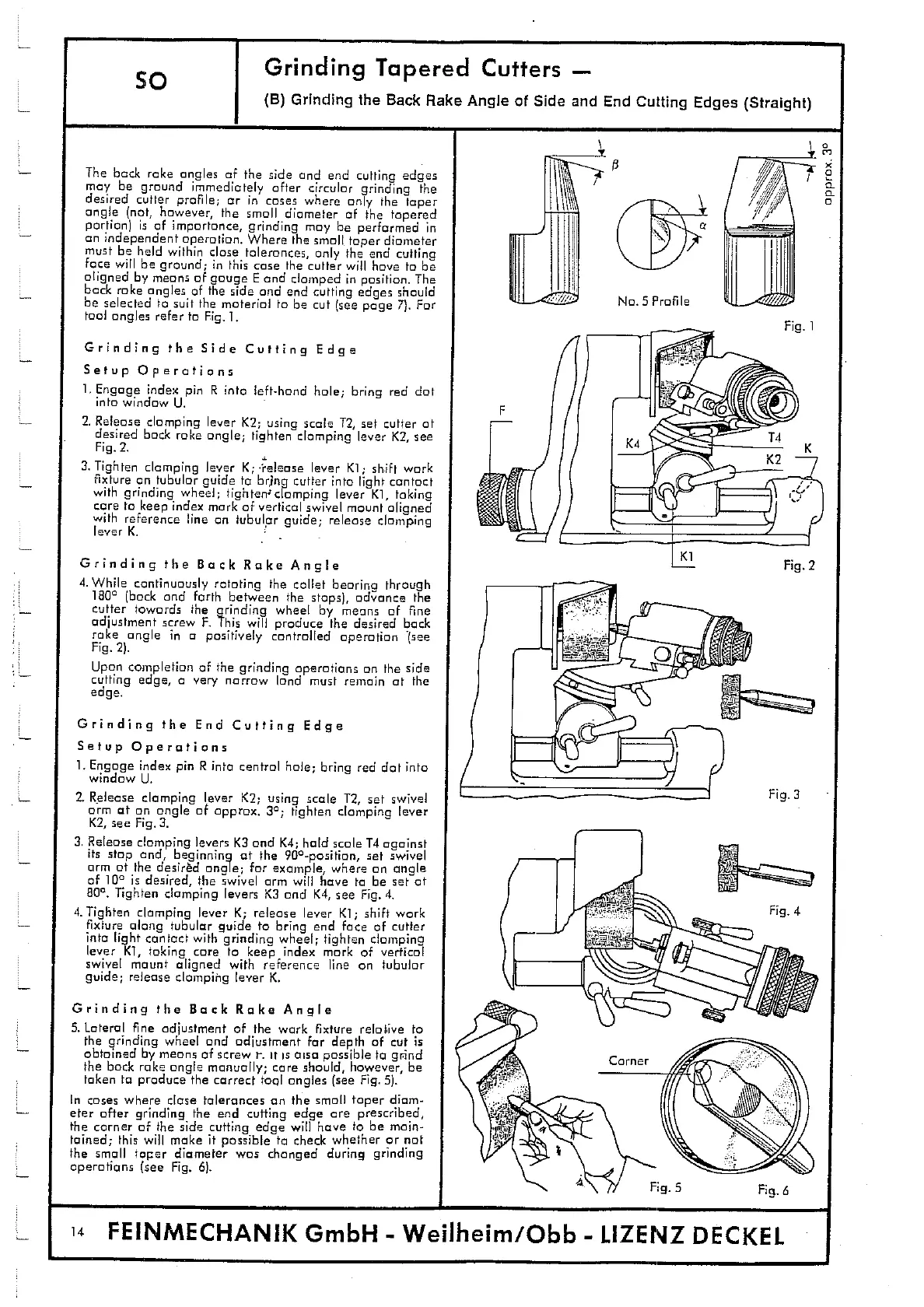

Pi- 1

Fig. 5

so

Grinding Tapered Cutters -

(B) Grinding the Back Rake Angie of Side and End Cutting Edges (Straight)

The bock rake angles of the side and end cutting edges

may be ground immediately after circular grinding the

desired cutter profile; or in cases where only the taper

angle (not, however, the small diameter of the tapered

portion) is of importance, grinding may be performed in

an independent operation. Where the small taper diameter

must be held within close tolerances, only the end cutting

face will be ground

;

in this case the cutter will have to be

aligned by means of gauge E and clamped in position. The

back rake angles of the side and end cutting edges should

be selected to suit the material to be cut (see page 7). For

tool angles refer to Fig. 1.

Grinding the Side Cutting Edge

Setup Operations

1.

Engage index pin R into left-hand hale; bring red dot

into window U.

2.

Release clamping lever K2; using scale T2, set cutter at

desired back rake angle

;

tighten clomping lever K2, see

Fig. 2.

3.

Tighten clamping lever K; "release lever Ki

;

shift work

fixture on tubular guide to bring cutter into light contact

with grinding wheel; tightenclomping lever Ki, taking

care to keep index mark of vertical swivel mount aligned

with reference line on tubular guide; release clamping

lever K.

Grinding the Bock Rake Angie

4.

While continuously rotating the collet bearing through

1600 (bock and forth between the stops), advance the

cutter towards the grinding wheel by means of fine

adjustment screw F. This will produce the desired bock

rake angle in a positively controlled operation (see

Fig. 2).

Upon completion of the grinding operations on the side

cutting edge, a very narrow land must remain at the

edge.

Grinding the End Cutting Edge

Setup Operations

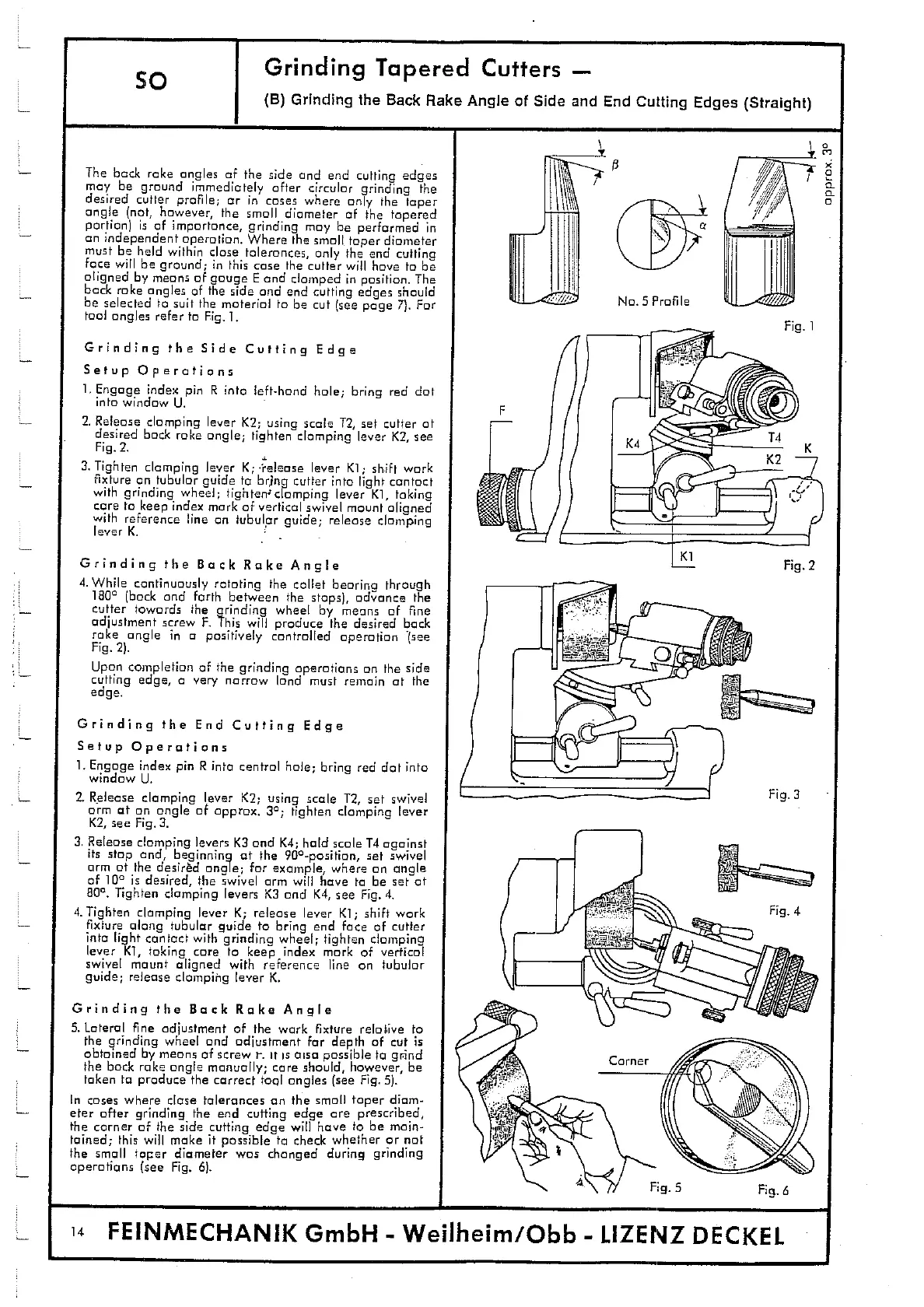

1.

Engage index pin R into central hale

;

bring red dot into

window U.

2.

Release clomping lever K2; using scale T2, set swivel

arm at an angle of approx. 30; tighten clamping lever

K2, see Fig. 3.

3.

Release clomping levers K3 and K4; hold scale T4 against

its stop and, beginning

of

the 90

0

-positian, set swivel

arm at the desired angle; for example, where an angle

of

100

is desired, the swivel arm will have to be set at

80

0

. Tighten clamping levers K3 and K4, see Fig. 4.

4.

Tighten clamping lever K; release lever KI; shift work

fixture along tubular guide to bring end face of cutter

into light contact with grinding wheel; tighten clamping

lever K1, taking care to keep index mark of vertical

swivel mount aligned with reference line on tubular

guide; release clamping lever K.

Grinding the Back Rake Angle

5.

Lateralfine adjustment of the work Fixture relative to

the grinding wheel and adjustment for depth of cut is

obtained by means of screw i

-

. iris aisa passible to grind

the back rake angle manually; care should, however, be

taken to produce the correct tool angles (see Fig. 5).

In cases where close tolerances an the small taper diam-

eter after grinding the end cuffing edge are prescribed,

the corner of the side cuffing edge will have to be main-

tained; this will make it possible to check whether or not

the small taper diameter was changed during grinding

operations (see Fig. 6).

c

I

1

14

FEINMECHANIK GmbH — Weilheim/Qbb — LIZENZ DECKEL

Loading...

Loading...