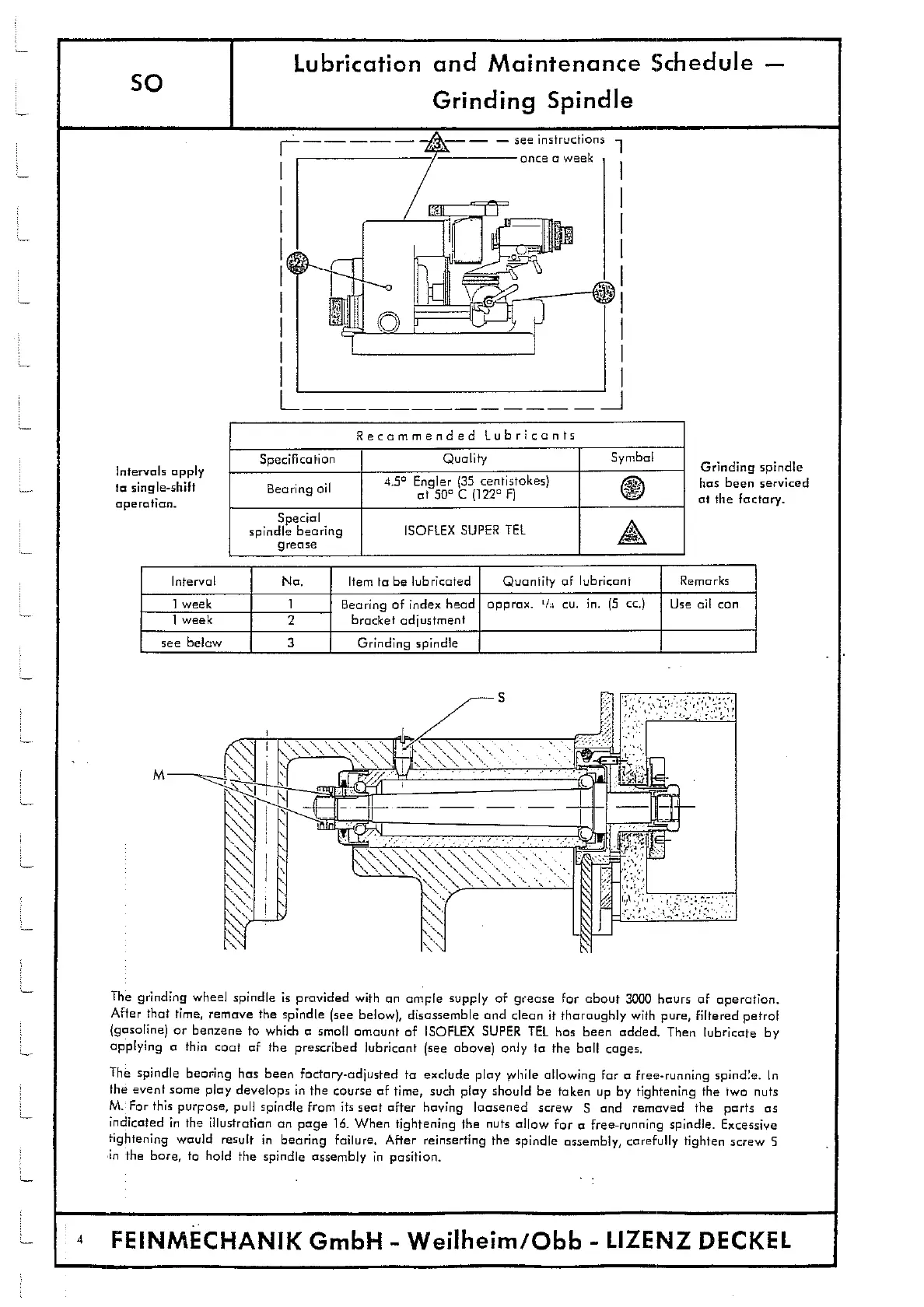

Lubrication and Maintenance Schedule -

so

Grinding Spindle

- - see instructions

1

once a week

I

I

Intervals apply

to single-shift

operation.

I

Recommended Lubricants

Specification

Quality

Symbol

4.5° Engler (35 centistokes)

Bearing oil

at 50° C (122° F)

Special

spindle bearing

ISOFLEX SUPER TEL

grease

Grinding spindle

has been serviced

at the factory.

Interval

No.

Item to be lubricated

Quantity of lubricant

Remarks

H

i week

1

Bearing of index head opprax_

li

cu. in. (5 cc.)

Use oil can

1 week

2

bracket adjustment

see below

3

Grinding spindle

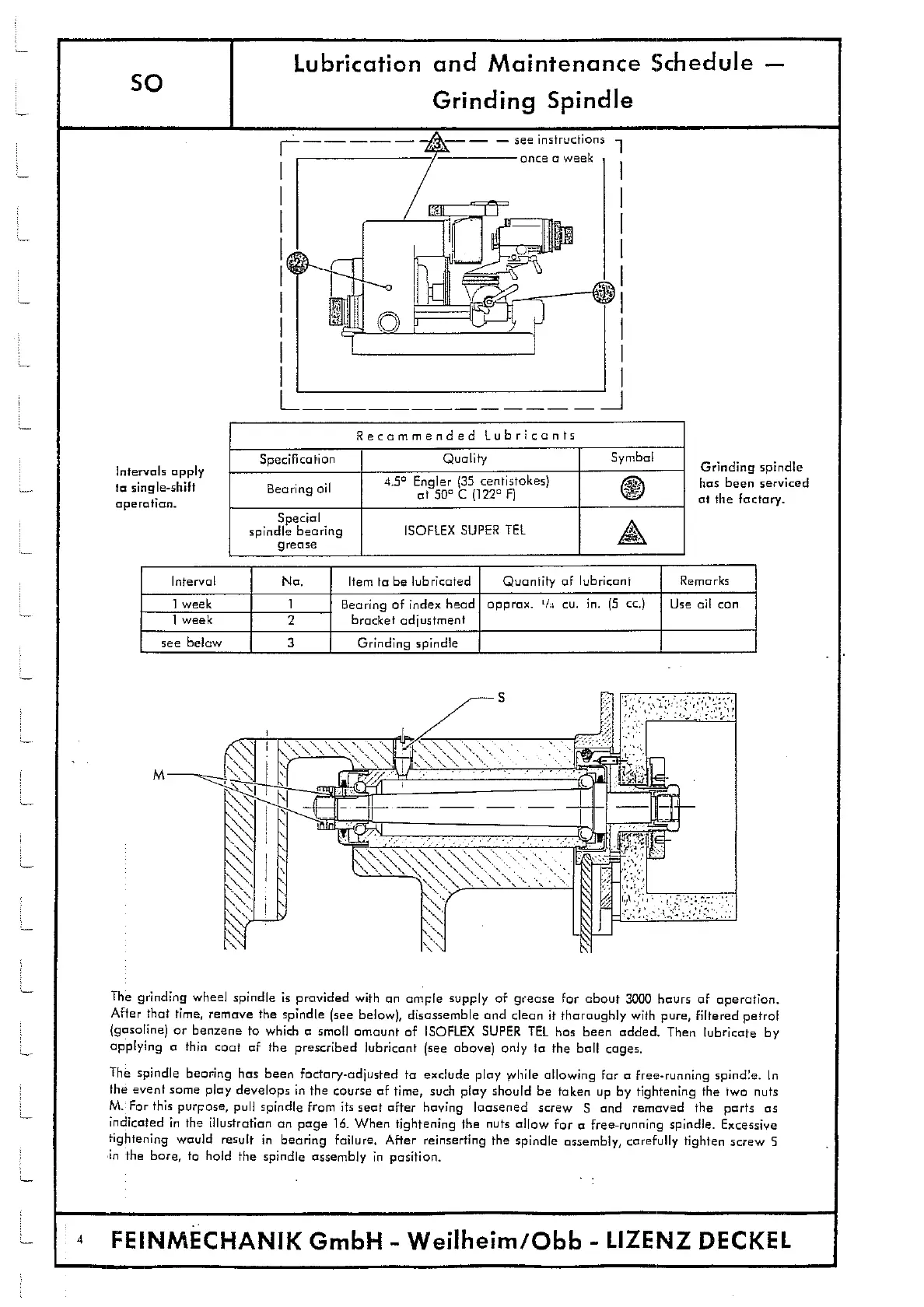

M

The grinding wheel spindle is provided with an ample supply of grease for about 3000 hours of operation.

After that time, remove the spindle (see below), disassemble and clean it thoroughly with pure, filtered petrol

(gasoline) or benzene to which a small amount of ISOFLEX SUPER TEL has been added. Then lubricate by

applying a thin coat of the prescribed lubricant (see above) only to the ball cages.

The spindle bearing has been factory-adjusted to exclude ploy while allowing for a free-running spinde. In

the event some play develops in the course of time, such play should be taken up by tightening the two nuts

M. For this purpose, pull spindle from its seat after having loosened screw S and removed the parts as

indicated in the illustration an page 16. When tightening the nuts allow for a free-running spindle. Excessive

tightening would result in bearing failure. After reinserting the spindle assembly, carefully tighten screw S

in the bore, to hold the spindle assembly in position.

I

4

FEINMECHANIK GmbH - Weilheim/Obb - LIZENZ DECKEL

Loading...

Loading...