DECTRON

5. Check that the refrigerant condenser pressure is in one of the following ranges:

R22 R134A R407C R410A

225-275 145 - 181 245 - 300 340 - 420

PSIG PSIG PSIG PSIG

6. Allow the unit to run in dehumidification mode for at least 20 minutes, then read the compressor discharge-gas

temperature using the remote-reading thermometer (by others) set up under Prepare to Adjust Expansion

Valve. The temperature should be in one of the following ranges:

7. (a) If the compressor discharge-gas temperature is too low, close the expansion valve(s) 1/2 turn at a time,

allowing at least 15 minutes between adjustments, until the compressor discharge-gas temperature is in the

proper range for the compressor type.

(b)If the compressor discharge-gas temperature is too high, open the expansion valve(s) 1/2 turn at a time,

allowing at least 15 minutes between adjustments, until the compressor discharge-gas temperature is in the

proper range for the compressor type.

(c)Where each refrigeration circuit has two or more expansion valves, adjust the expansion valves together as

much as possible. Complete the adjustments by referring to the previous page, and, using the thermometer

probes discussed there, adjust the associated expansion valves to keep the average

expansion-valve-bulb

temperatures as near the same as possible, while meeting the requirements of (a) and (b) above.

8. Allow the DRY-O-TRON

®

to operate continuously for at least 1 hour after the last adjustment, then check to be

sure the compressor discharge-gas temperature is in the correct range for the type of compressor.

Dectron, Inc. March 2012

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Startup Adjust Expansion Valve(s)

Data subject to change without notice.

234

STARTUP

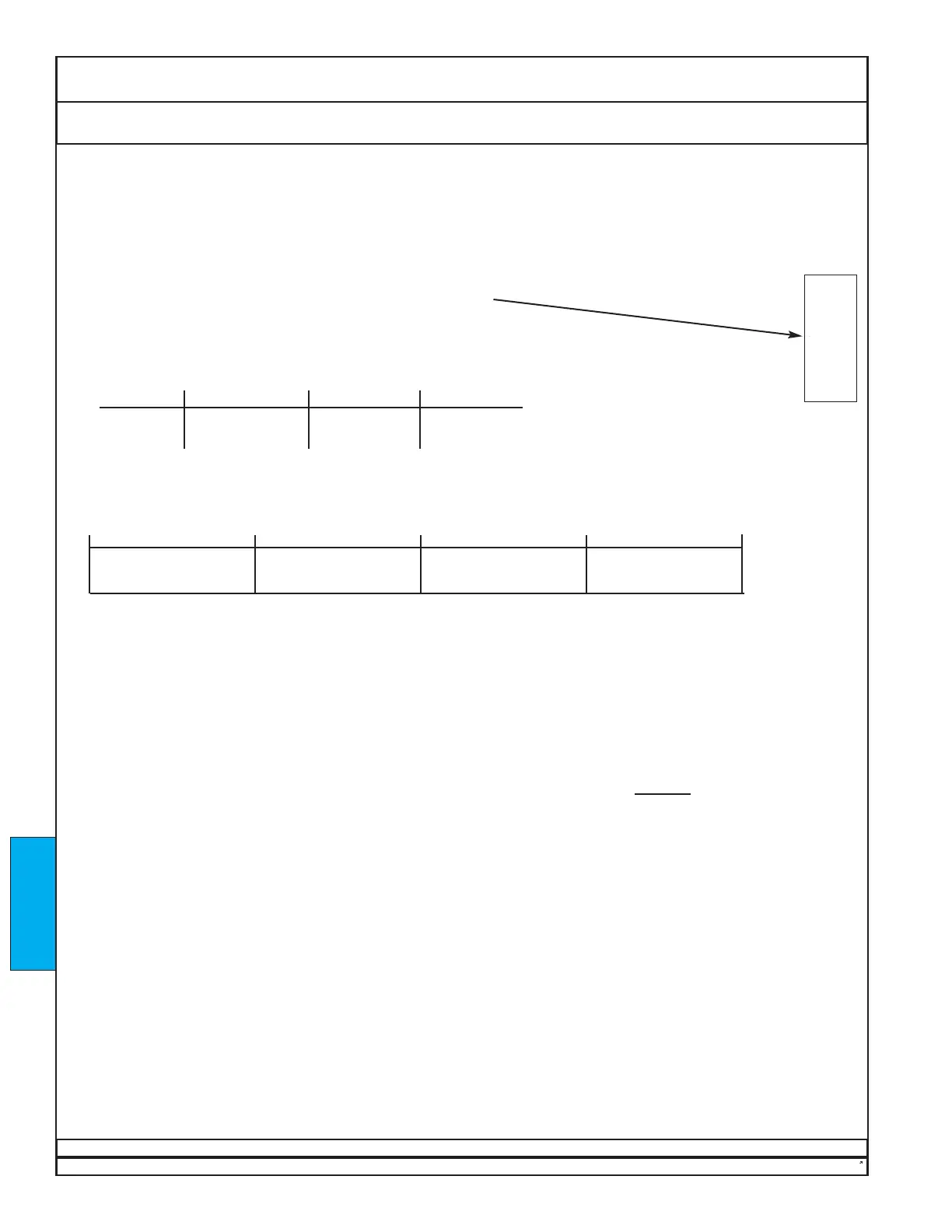

R-22 R134A R-407C R-410A

180°F (82°C) to 160°F (77°C) to 160°F (71°C) to 150°F (66°C) to

200°F (93°C) 180°F (88°C) 180°F (82°C) 170°F (77°C)

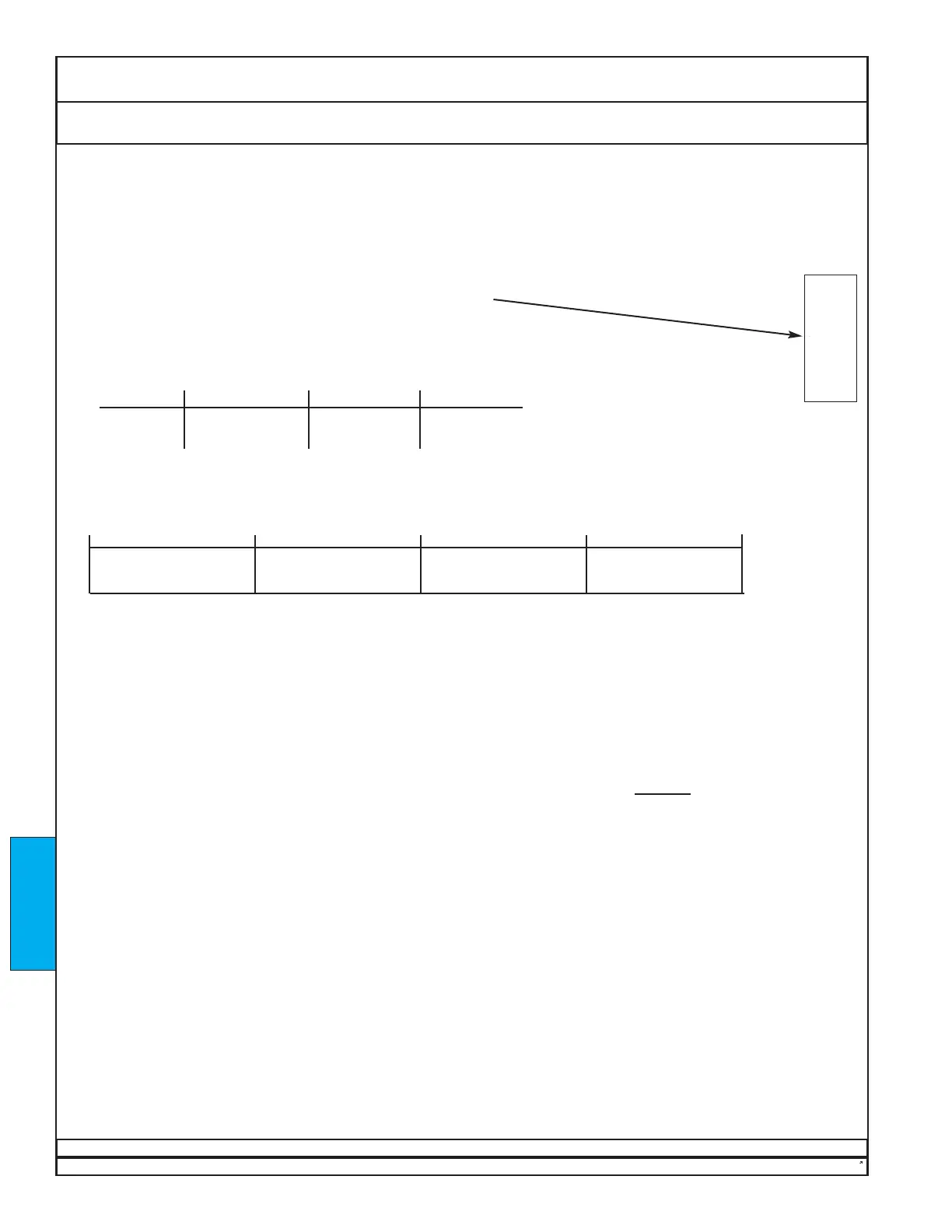

DRY-O-TRON ®

MODEL #:

SERIAL #:

I.D.

D

ELECTRICAL RATING

460 V ac, 3 ph, 60 Hz

COMPRESSOR LRA RLA

COMPRESSOR LRA RLA

COMPRESSOR LRA RLA

COMPRESSOR LRA RLA

BLOWER MOTOR HP FLA

BLOWER MOTOR HP FLA

BLOWER MOTOR HP FLA

COND. FAN MOTOR HP FLA

COND. FAN MOTOR HP FLA

PUMP MOTOR HP FLA

ENTHALPY MOTOR HP FLA

ELECTRIC HEATER kW A

Max. L.A.T. (°F)

SERVICE POWER

SPACE HEATING COIL

PSIG Max.

MCA A MAX. FUSE/ CKT. BKR.*

15

A

*(HACR type per NEC)

R-22 FACTORY CHARGE

lbs

AIR VOLUME CFM

BELT SIZE

WIRING DIAGRAM

REFRIGERANT DESIGN PRESSURES: HIGH/LOW 300/150 PSIG

COMFORMS TO ANSI/UL STD 1995

CERTIFIED TO STD CAN/CSA-

C22.2 NO. 236

LR 45671

FABRIQUÉ AU CANADA / MADE IN CANADA

REF.:

POOL # 1: ft² POOL # 3: ft²

E.W.T.: °F E.W.T.: °F

POOL # 2: ft² POOL # 4: ft²

E.W.T.: °F E.W.T.: °F

AIR TEMP.: °F R.H.: %

R-22 TOTAL SYSTEM CHARGE:

lbs

OIL TO BE ADDED AT START-UP:

oz

OIL TYPE:

MAX. LENGTH OF REF. LINES (ONE WAY) ft

BETWEEN D.O.T. & REMOTE CONDENSER:

LINE SIZE:

AIR COOLED COND. MODEL #:

HOT GAS: in

LIQUID: in

50379

1. Be sure the compressor(s) of the circuit being adjusted is running. If not, return to Startup - Enable Operation.

2. If the unit does not operate in dehumidification mode (status message DEHUMIDIFY ON, see Operation -

Controller Messages.), then temporarily decrease the humidity set point to cause it to do so. (See Startup -

Adjust Set Points)

3. Be sure that the refrigerant sight glass is completely full of liquid, with no bubbles. If bubbles are present,

return to step 1 or contact Dectron.

4. Determine the type of refrigerant from the unit nameplate.

Loading...

Loading...