ADJUSTING LOWER

BLADE GUIDES AND

GUIDE BRACKET

1. DISCONNECT THE MACHINE FROM THE POWER

SOURCE.

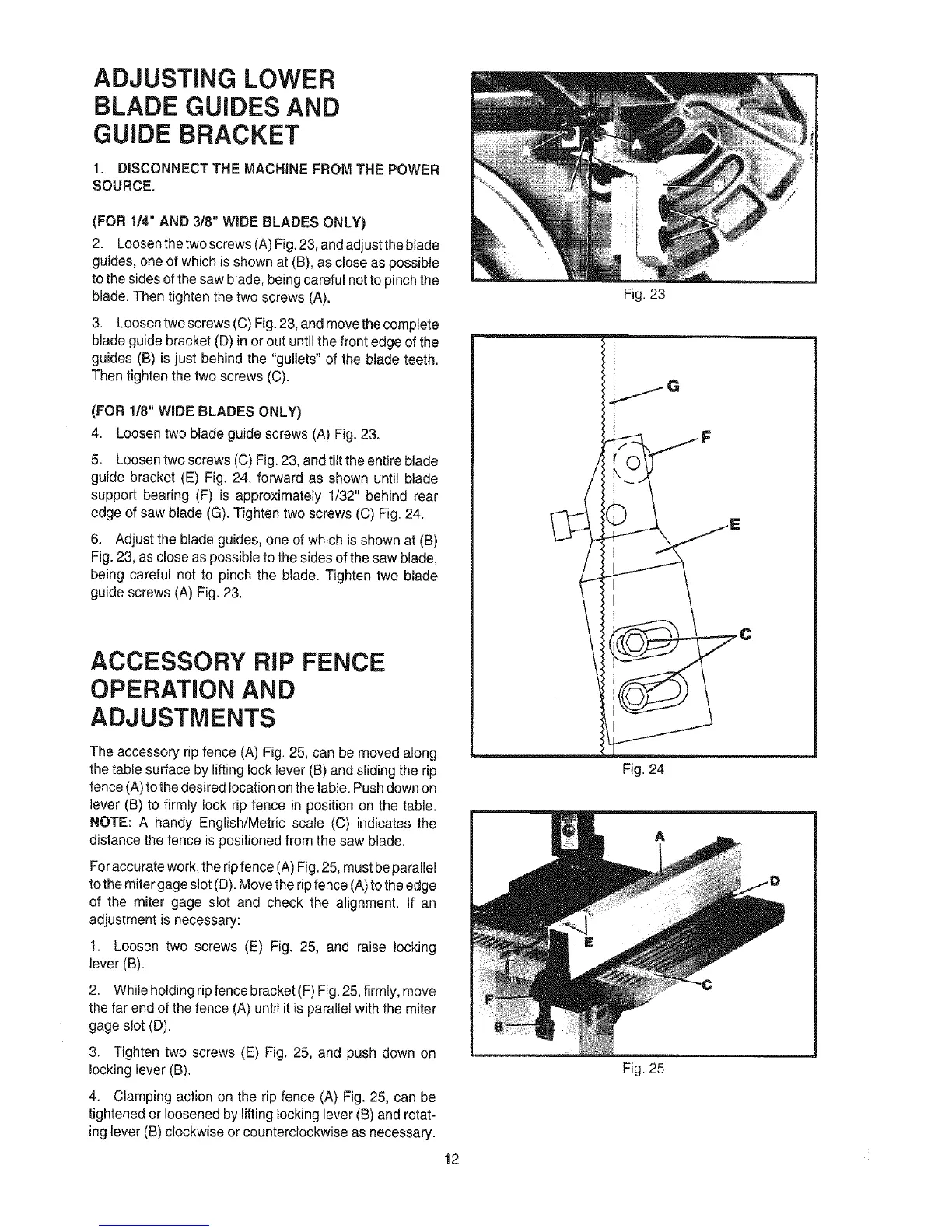

(FOR 1/4" AND 3/8" WiDE BLADES ONLY)

2. Loosen the two screws (A) Fig. 23, and adjust the blade

guides, one of which is shown at (B), as close as possible

to the sides of the saw blade, being careful not to pinch the

blade. Then tighten the two screws (A).

3. Loosen two screws (C) Fig. 23, and move the complete

blade guide bracket (D) in or out until the front edge of the

guides (B) is just behind the "gullets" of the blade teeth.

Then tighten the two screws (C).

(FOR 1/8" WiDE BLADES ONLY)

4. Loosen two blade guide screws (A) Fig. 23.

5. Loosen two screws (C) Fig. 23, and tilt the entire blade

guide bracket (E) Fig. 24, forward as shown until blade

support bearing (F) is approximately 1/32" behind rear

edge of saw blade (G). Tighten two screws (C) Fig. 24.

6. Adjust the blade guides, one of which is shown at (B)

Fig. 23, as close as possible to the sides of the saw blade,

being careful not to pinch the blade. Tighten two blade

guide screws (A) Fig. 23.

ACCESSORY RiP FENCE

OPERATION AND

ADJUSTMENTS

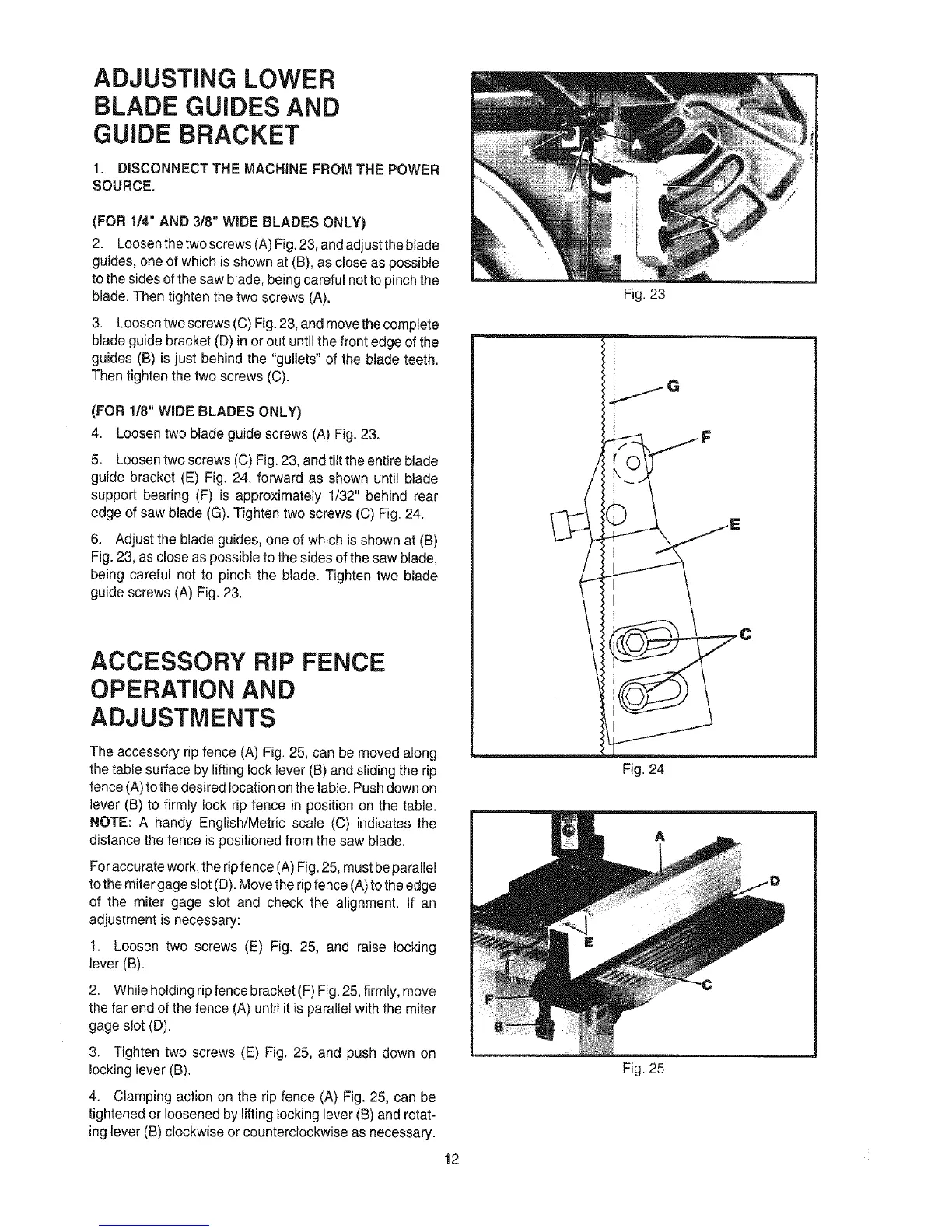

The accessory rip fence (A) Fig. 25, can be moved along

the table surface by liftinglock lever (B) and sliding the rip

fence (A) to the desired location on the table. Push down on

lever (B) to firmly lock rip fence in position on the table.

NOTE: A handy English/Metric scale (C) indicates the

distance the fence is positioned from the saw blade.

For accurate work, the rip fence (A) Fig. 25, must beparallel

tothe miter gage slot (D). Move the rip fence (A) to the edge

of the miter gage slot and check the alignment. If an

adjustment is necessary:

1. Loosen two screws (E) Fig. 25, and raise locking

lever (B).

2. While holding ripfence bracket (F) Fig. 25, firmly, move

the far end of the fence (A) until it is parallel with the miter

gage slot (D).

3. Tighten two screws (E) Fig. 25, and push down on

locking lever (B).

4. Clamping action on the rip fence (A) Fig. 25, can be

tightened or loosened by liftinglocking lever (B) and rotat-

ing lever (B) clockwise or counterclockwise as necessary.

12

Fig. 23

i jG

1

C

'Ul

Fig. 24

Fig. 25

Loading...

Loading...