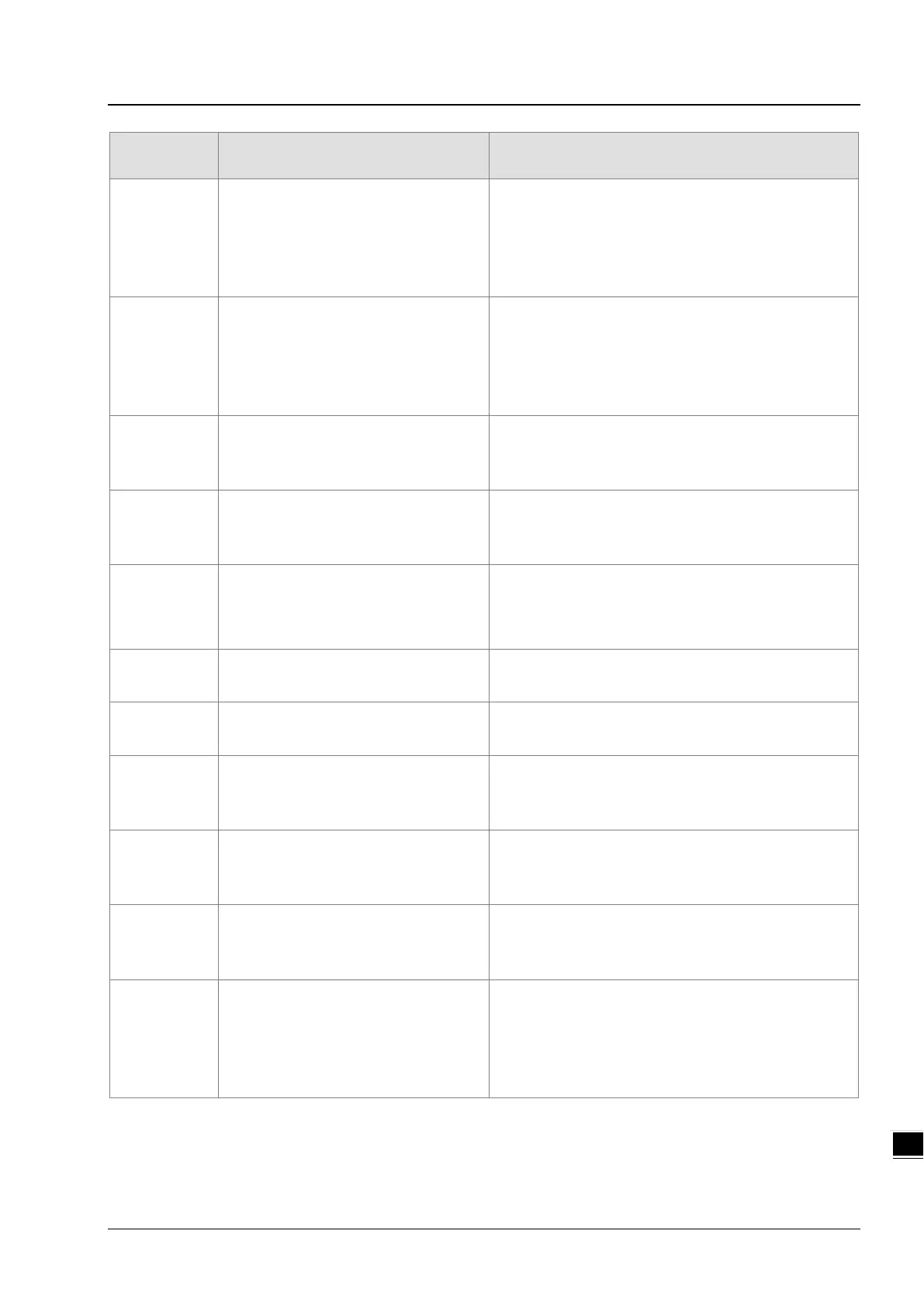

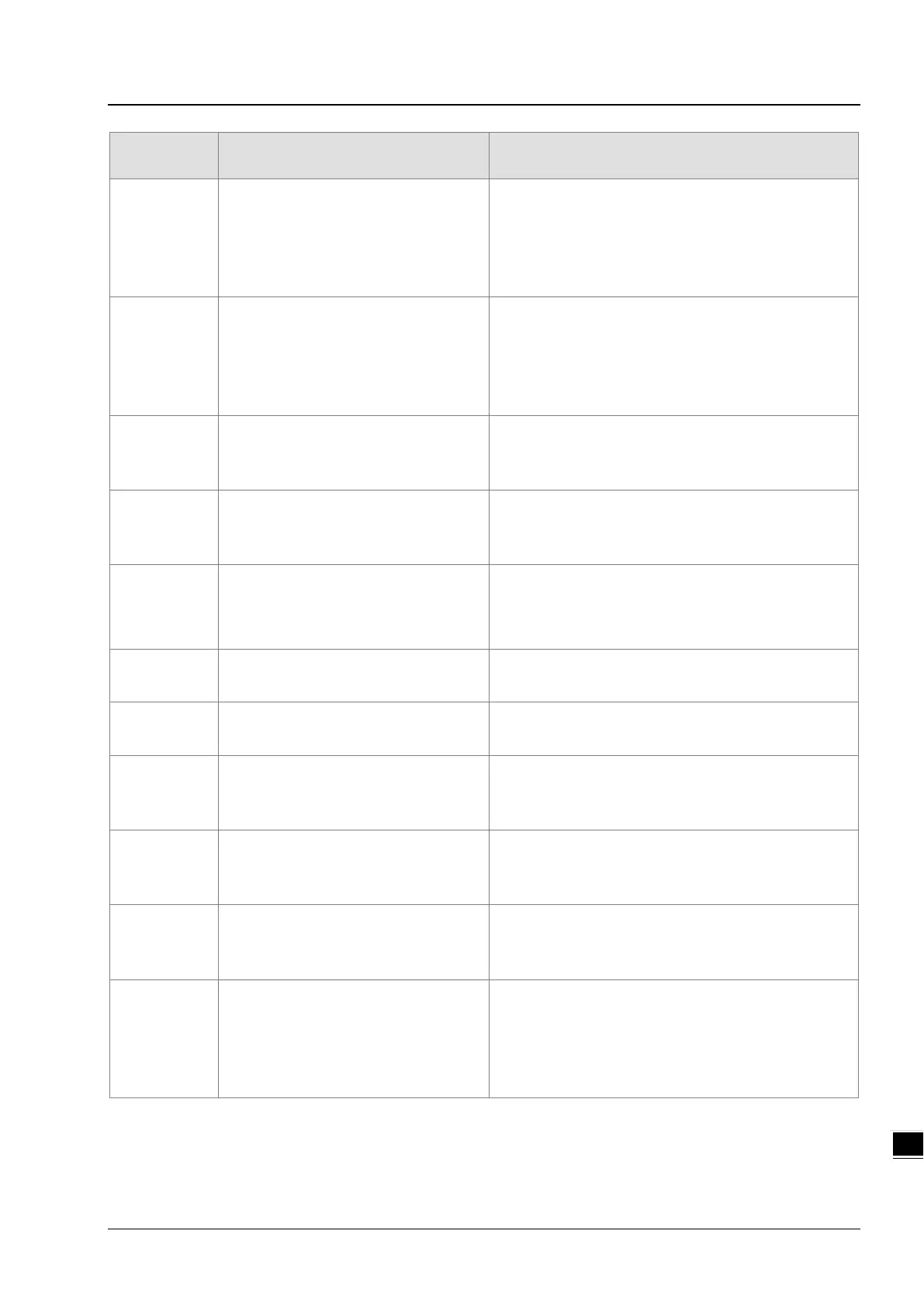

Chapter 9 Troubleshooting

9-43

Error Code Description Corrective action

16#202C

|

16#204B

I/O interrupt service routine 0 does not

exist.

|

I/O interrupt service routine 31 does not

Download I/O interrupt service routine 0 (I/O interrupt 0)

|

Download I/O interrupt service routine 31 (I/O interrupt

31)

16#2054

|

16#2127

External interrupt service routine 40 does

not exist.

|

External interrupt service routine 251

Download external interrupt service routine 40 (external

interrupt 40)

|

Download external interrupt service routine 251 (external

16#2128

An action in a sequential function chart is

incorrectly assigned qualifiers related to

Check whether qualifiers related to time are duplicated

when setting SFC action.

16#2129

The modifier R is assigned to an action in

a sequential function chart incorrectly.

Check whether there are conflict settings between

properties when setting SFC action.

16#3040

Data in E-CAM exceeds the setting

range or does not exist.

Cause: the E-CAM number has been input in the

function block but it exceeds the setting range

Action: modify the E-CAM number and set it within the

16#3100

Input parameters exceed the available

Check whether the input parameters exceed the

16#3102

An error occurs in a sub-function block

inside the function block.

Restart the function block instruction.

16#3103

The distance between the detecting

sensors used for identifying exeptional

bags is a negative value.

Check whether the positions of the detecting sensors are

correct.

16#3104

Phasing is executed again before the

previous phasing is completed.

Cause: the instruction is executed again when Done is

still False.

Action: restart the instruction again.

16#3105

Superimposing is executed again before

the previous superimposing is

Cause: the instruction is executed again when Done is

still False.

Action: restart the instruction again.

16#3106

Chain position compensation is triggered

before the previous compensation is

completed.

Cause: the master axis moves too fast to allow the

previous compensation to be finished. In this case, the

compensation is triggered again.

Action: adjust all packaging related parameters

according to the application requirements.

Loading...

Loading...