AH Motion Controller – Operation Manual

9-52

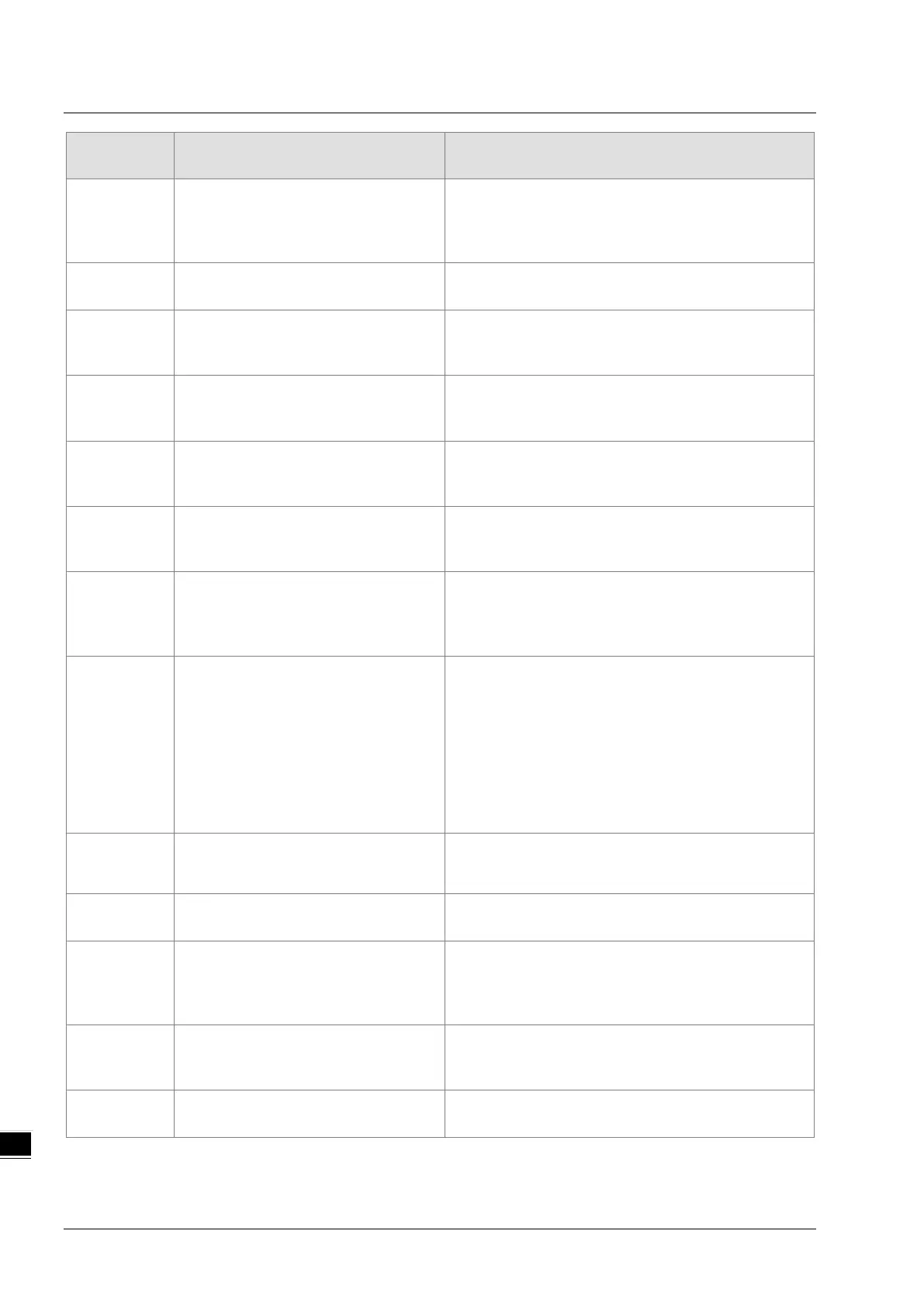

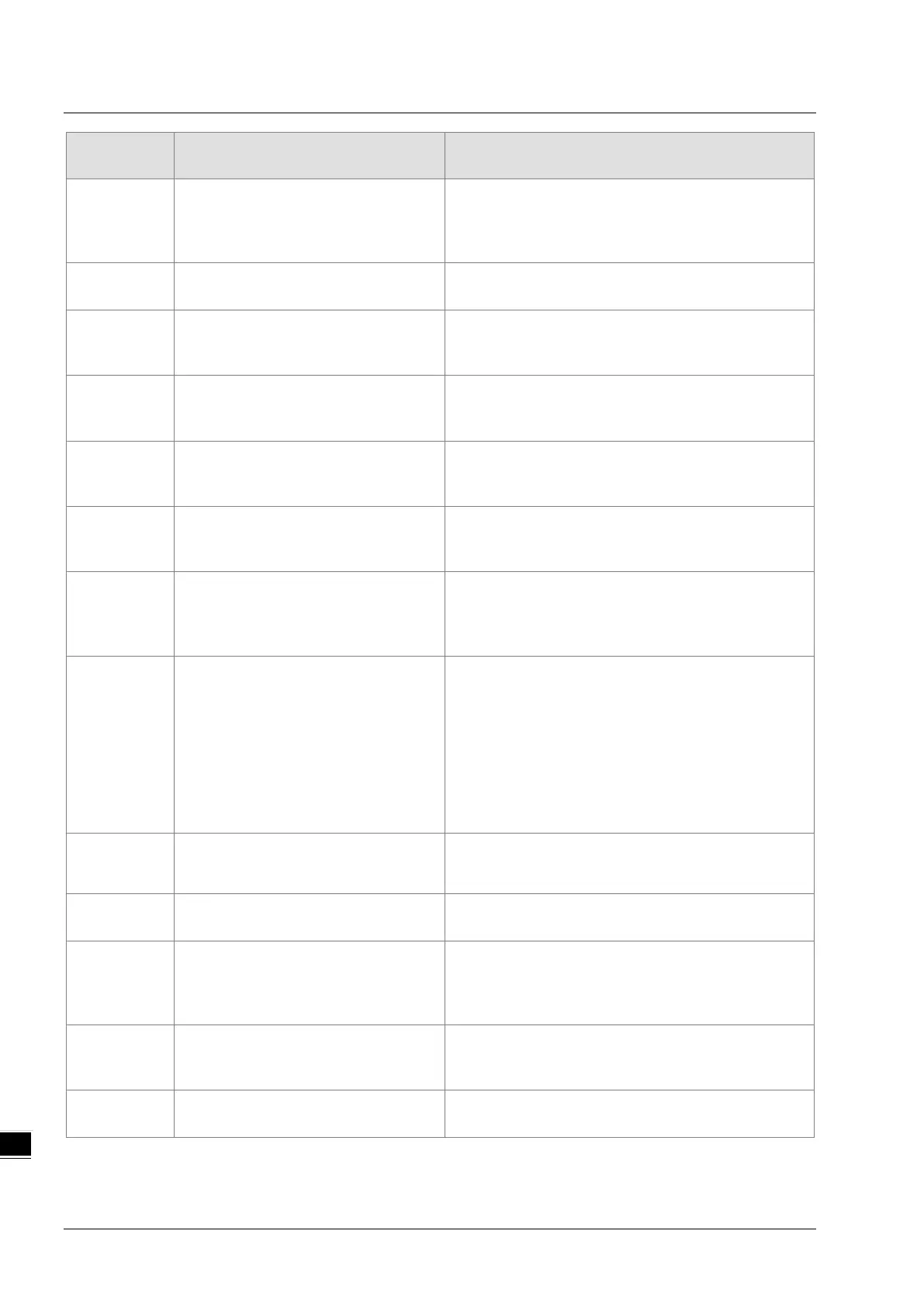

Error Code Description Corrective action

16#3919

GearInPos the main axis moves in

opposite direction

Cause: GearInPos the main axis moves in opposite

direction

Action: make the main axis and the auxiliary axis move

16#3920

GearInPos acceleration is set too small

the acceleration or deceleration is set too small

Action: increase the acceleration or deceleration

16#3921

GearInPos MasterStartDistancs

exceeds setting range

MasterStartDistancs setting out of range

Action: check the starting and ending position of the

16#3922

GearInPos slave synchnoization

position is set too small

Cause: SlaveSyncPosition is set too small

Action: increase the setting value of SlaveSyncPosition,

or increase the acceleration or deceleration

16#3923

GearInPos slave synchnoization

position is set too big

Cause: SlaveSyncPosition is set too big

Action: decrease the setting value of SlaveSyncPosition,

or increase the acceleration or deceleration

16#3924

GearInPos the velocity of the main axis

changes when the engagement started

Cause: before InSync, the velocity of the main axis

changes

Action: before InSync, fix the velocity of the main axis

16#3950

Capture cannot be used when the pulse

speed is over 1MHz

Cause: Capture cannot be used when the pulse speed is

over 1MHz

Action: slow dow to capture the pulse speed and restart

16#3951

DFB_CamCurve2 setting error

Cause: CamCurve2 input error (e.g. if Concatenate is not

True, or other input parameters are out of range)

Action:

1. Turn the PLC off and then on, execute the

DFB_CamCurve2 and first set concatenate option to

False. When the function block is Done, set the

concatenate to True and then execute the

DFB_CamCurve2 to clear the error.

2. Check other parameters for any errors.

16#3953

Capture2 uses the same channel

number repeatedly

Cause: more than two groups of DFB_Capture2 use the

same channel number

Action: use other un-used channel number instead

16#3954

Torque ramp fail to write

Cause: TorqueRamp is set to 0.

Action: TorqueRamp cannot be set as 0.

16#3955

Torque velocity fail to write

Cause: MC_TorqueControl value is not supported by the

servo

Action: check the servo manual to see the supported

16#3A00

Cam table setting error

Cause: the designated Cam table is not existed.

Action: add a new Cam table or set up a new setting in

16#3A01

CamIn master setting error

setting error in the source of the master axis

Action: set up the source of the master axis again

Loading...

Loading...