The D1000

Installation and

Service

Version 2.1

1 7

Cleaning the Hood

To remove built up grease and cooking debris, clean the unit thoroughly with mild detergent and water. Be

careful when using abrasive cleaning pads as they may scratch or mar the stainless steel surfaces. The grease

entrapment lter, front discharge grille and grease tray are dishwasher safe. The carbon lter cannot be washed,

and should be replaced periodically as needed.

Inspect the nozzle caps

The nozzle caps should be inspected and cleaned. All 5 nozzles should have protective caps installed. If neces-

sary, remove the caps and check for build up of debris or any signs of clogging of the nozzle orice. If clogging

is suspected, remove the nozzle with a 7/16” wrench, and ush with hot water until it ows freely through the

nozzle. Replace the nozzle and protective cap.

Replacement caps and nozzle O-rings are available from DFP or your distributor.

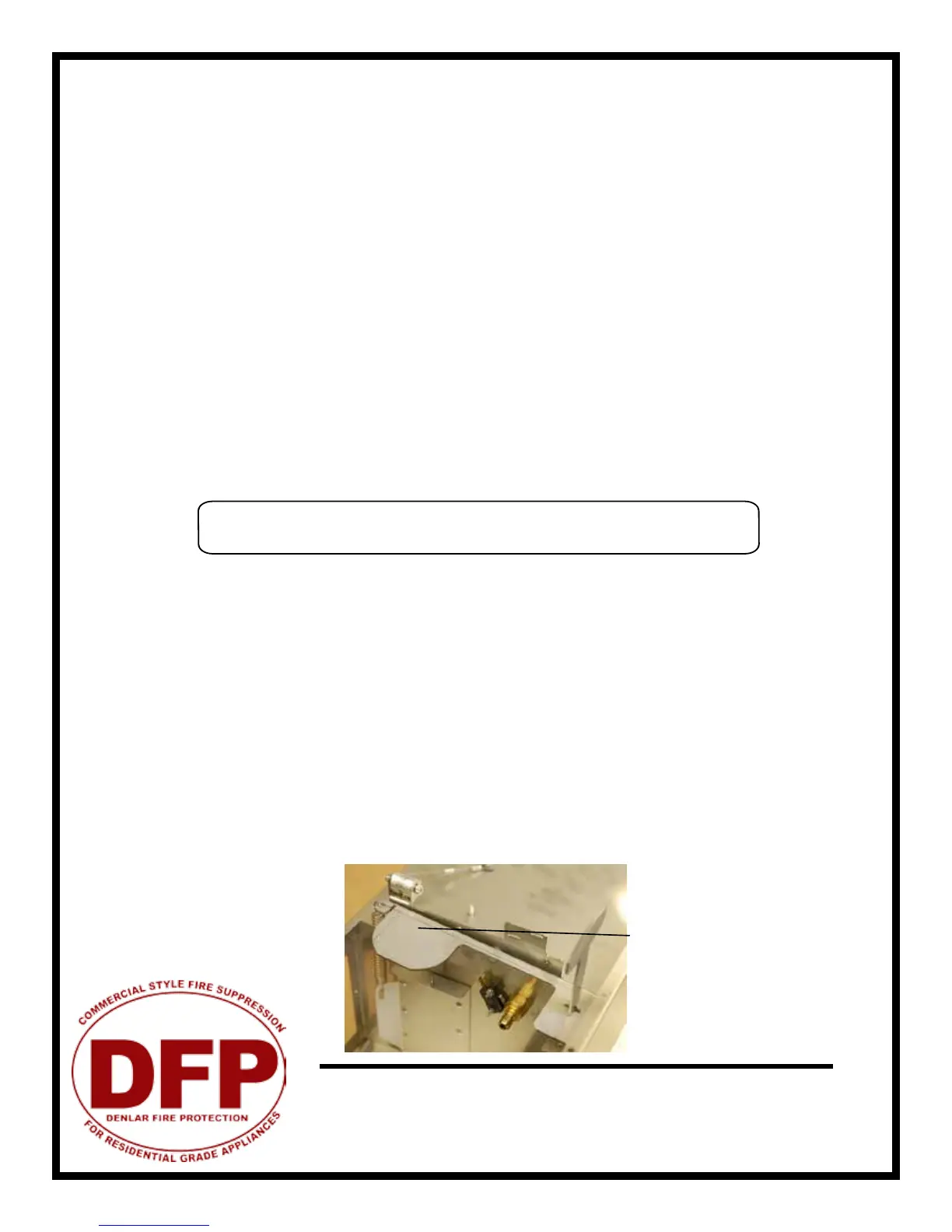

Inspect Fusible Link System*

Periodic inspection of the fusible link system ensures the unit is ready to work in the case of a re.

1. Place safety pin in tank valve.

2. Remove tank from hood.

3. Remove tension from cable system by loosening the turnbuckle.

4. If the fusible links need to be replaced, you may order some by calling your local distributor.

5. Inspect pulleys and cable. Pulleys should rotate freely and cable should be exible. Everything should be free

of grease build-up.

6. Tighten the turnbuckle, reapplying tension to the stainless steel rope, making sure the cable is running

through the pulleys properly and there are no kinks or knots.

WARNING: The protective caps stay on the nozzles at all times. In the event

of a discharge, the caps will blow o on their own.

Actuator arm under tension

in ready position

7. Reposition the tank.

8. Remove safety pin from tank valve.

*Each fusible link is date-stamped and must be replaced if expired or after 12 months of use.

Maintaining the System

Inspection Procedure

Loading...

Loading...