FEEDING TECHNOLOGY

11

If an inlet control is used then this monitors whether a feed part is in the separator. If there is no

feed part present at the start of a cycle or 60 seconds after the last separator procedure then a

warning signal is set off.

If a hose screw sensor is used then this monitors whether a feed part arrives at the screwdriver. If

no feed part arrives then the machine makes two attempts to reload before setting off a warning

signal.

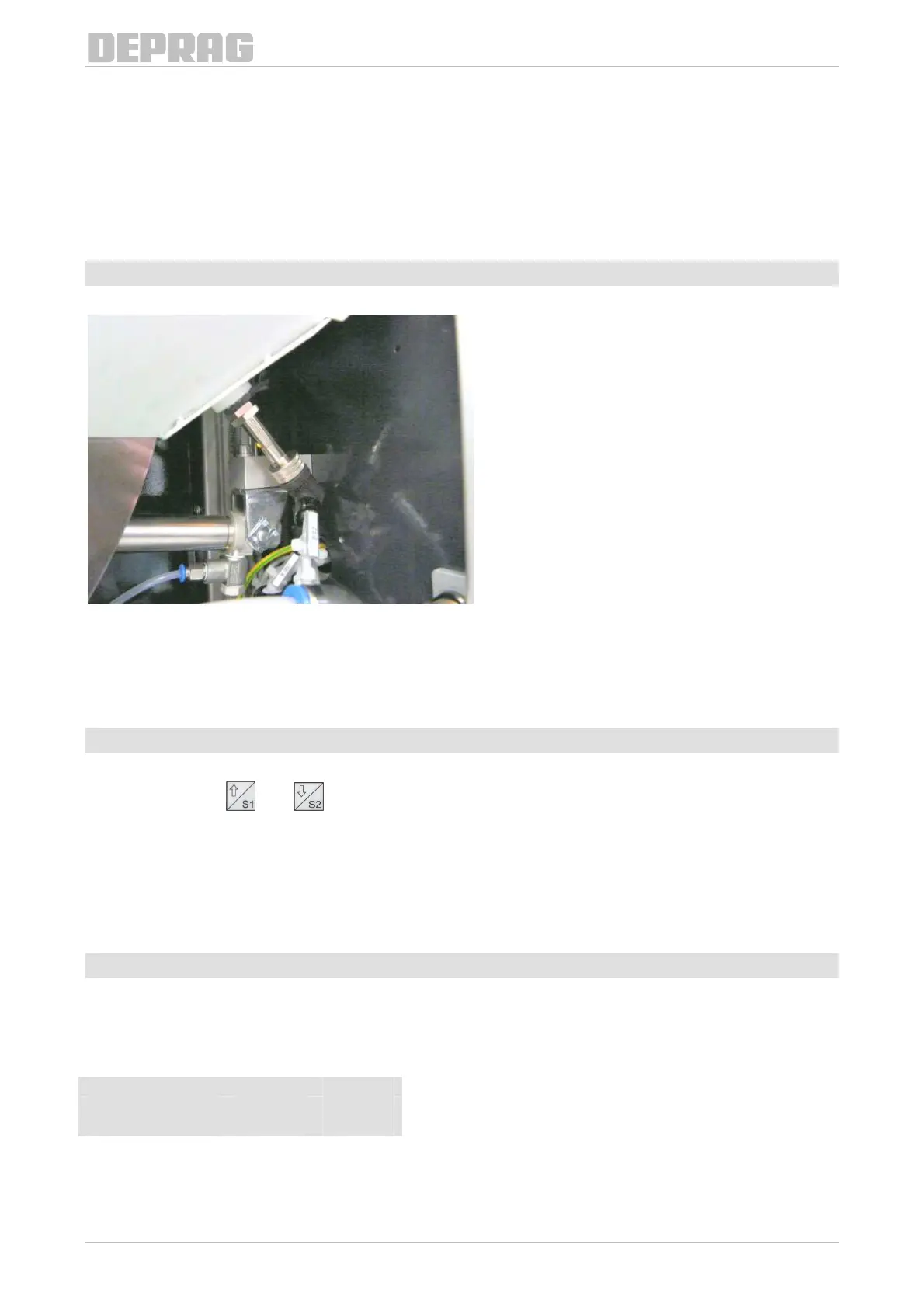

4.6 Fill level sensor (optional)

Image 5: fill level sensors underneath the bin – example of use

A fill level sensor is used to monitor the amount of feed parts in the bin. If the current fill level is not

sufficient to guarantee continuous feeding then the operator must refill the bin tso that there is a

continuous supply of feed parts to be processed.

4.7 User

The data for up to 10 different users can be registered. You can switch between users in the menu.

Press the buttons

and to select the required user number in the menu section USER. The

current user number is marked by an asterisk(*).

You can also switch between users using the optional RFID interface.

In the standard display screen the number of the current user is displayed in the upper right-hand

corner.

4.8 Times

4.8.1 Min. driver time

The minimum driver time is the minimum time the screwdriver must run before the controller

activates the inlet cycle.

Minimum time: 0 sec.

Maximum time: 5,0 sec.

Steps: 0,1 sec.

Loading...

Loading...