Model FP-700

FP-700 Instruction Manual Rev. 5.1 Page 1 of 46

1. Introduction

1.1 Description

Detcon Model FP-700 combustible gas sensors are non-intrusive “Smart” sensors

designed to detect and monitor combustible gases in air. Range of detection is 0-100%

LEL or 0-50% LEL. The sensor features an LED display of current reading, fault and

calibration status. The unit is equipped with standard analog 4-20mA and Modbus™ RS-

485 outputs. A primary feature of the sensor is its method of automatic calibration, which

guides the user through each step via fully scripted instructions displayed on the LED

display.

The microprocessor-supervised electronics are packaged in an encapsulated module and

housed in an explosion proof casting. The unit includes a 4 character alpha/numeric LED

used to display sensor readings, and the sensor’s menu driven features when the hand-held

programming magnet is used.

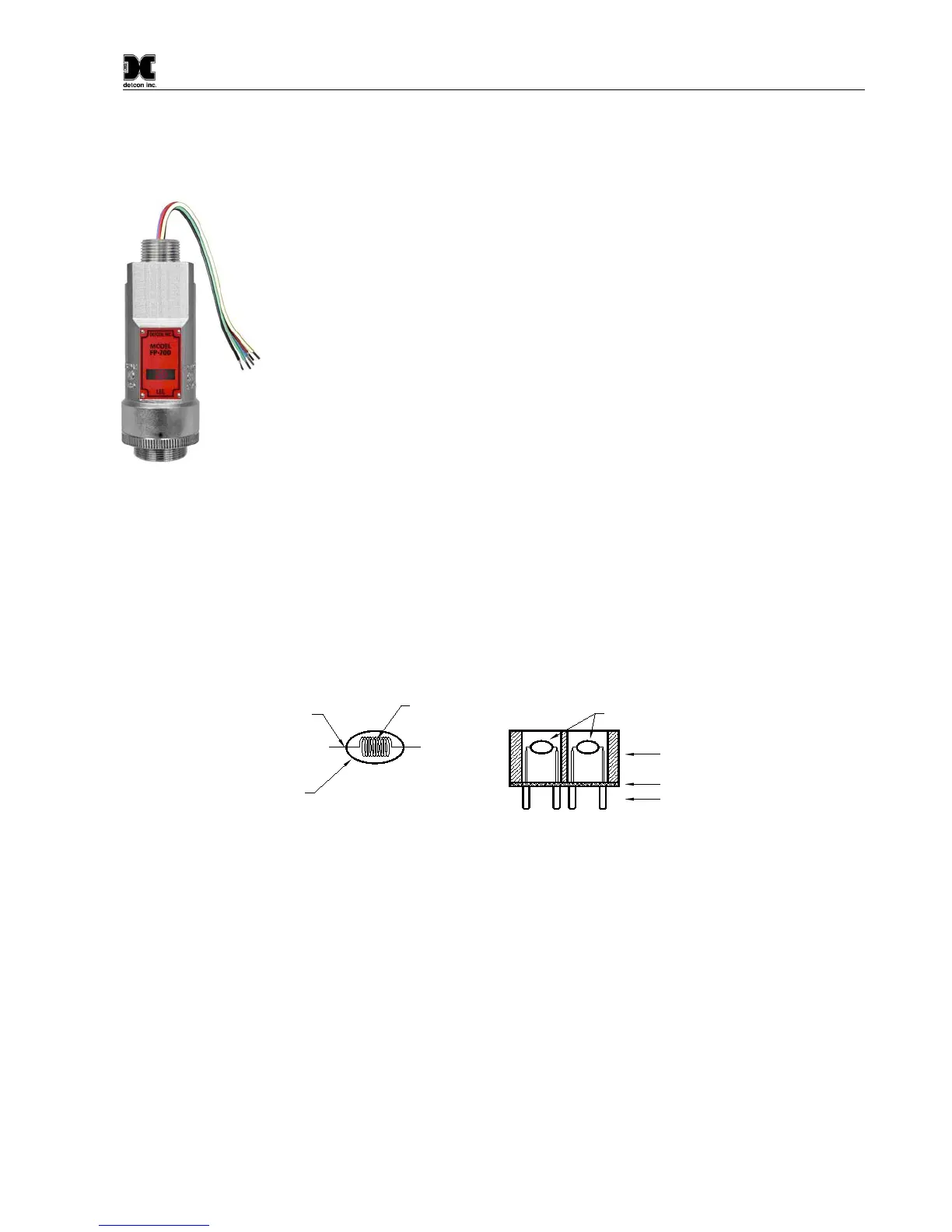

Catalytic Bead (Pellistor) Sensor Technology

The sensor technology is a poison-resistant catalytic bead type. Catalytic bead sensors show a strong response

to a long list of combustible gases. The sensor is supplied as a matched-pair of detector elements mounted in a

plug-in replaceable module. One bead is a catalytically active detector and the other is a non-active reference

detector. Each detector consists of a fine platinum wire coil embedded in aluminum oxide. A catalytic mixture

is applied to the active detector while the reference detector is treated so that oxidation of the gas does not occur.

The technique is referred to as non-selective and may be used to monitor most any combustible gas. Detcon

catalytic bead sensors are specifically designed to be resistant to poisons such as sulfides, chlorides, and

silicones. The sensors are characteristically stable and capable of providing reliable performance for periods

exceeding 5 years in most industrial environments.

Figure 1 Sensor Cell Construction

Principle of Operation

Method of detection is by diffusion/adsorption. Air and combustible gases pass through a sintered stainless steel

filter and contact the heated surface of both the active and reference detectors. The surface of the active detector

promotes oxidation of the combustible gas molecules while the reference detector has been treated not to support

this oxidation. The reference detector serves as a means to maintain zero stability over a wide range of

temperature and humidity.

When combustible gas molecules oxidize on the surface of the active detector, heat is generated, and the

resistance of the detector changes. Electronically, the detectors form part of a balanced bridge circuit. As the

active detector changes in resistance, the bridge circuit unbalances. This change in output is conditioned by the

amplifier circuitry, which is an integral part of the sensor design. The response and clearing characteristics of

the sensor are rapid and provide for the continuous and accurate monitoring of ambient air conditions.

Main Housing Insert

Printed Circuit Board

Gold Plated Pins

Platinum Wire

Construction

of Detector

Bead

Catalyst

Alumina Bead

Catalytic Beads

Loading...

Loading...