14

MaIntenanCe

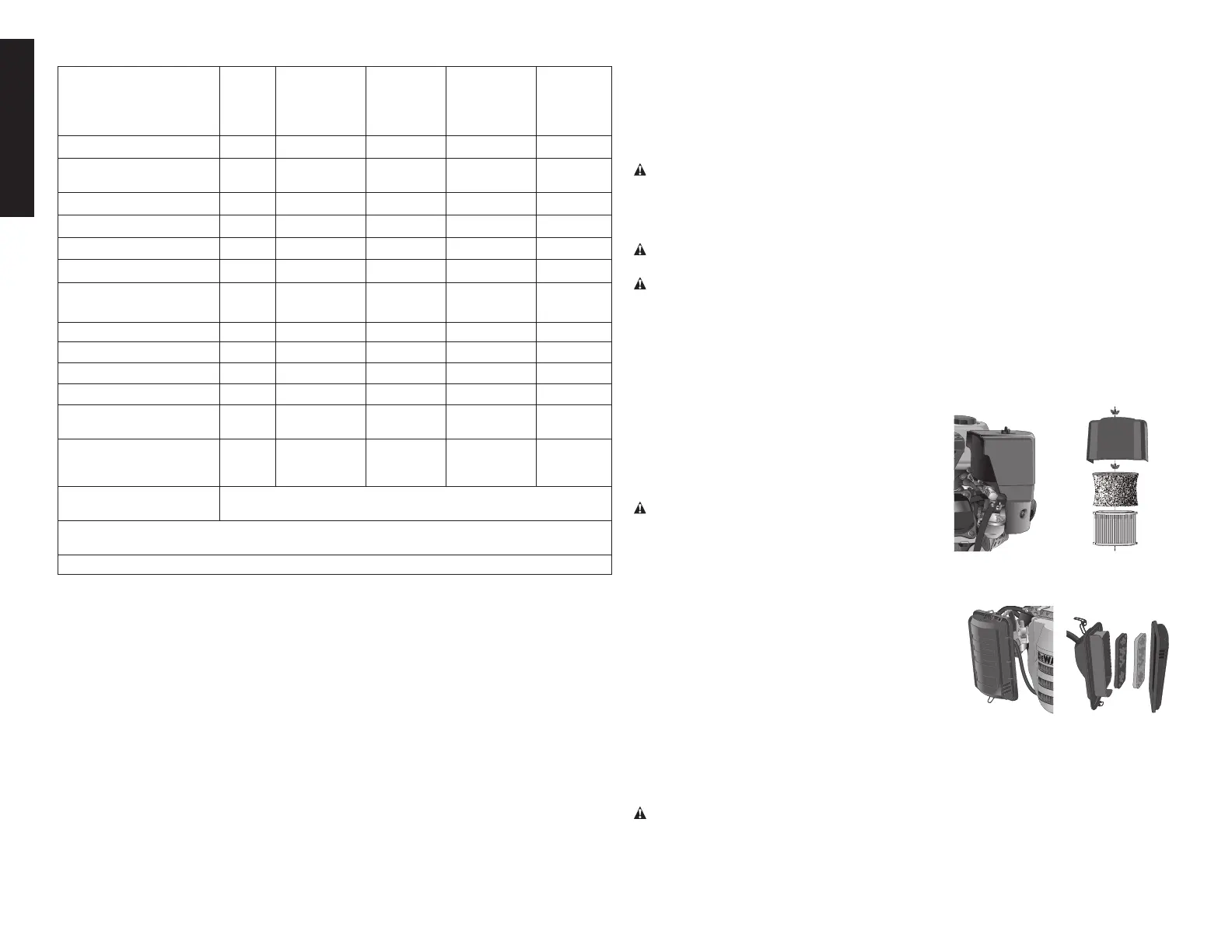

Procedure Daily 50 hours

or weekly

(whichever

comes first)

100 hours 150 hours

or monthly

(whichever

comes first)

500 Hours

Clean engine exterior

X

Cleanbatterypackand

charger

X

Checkoillevel

X

Change oil *

X(1)

Clean air filter

X(1)

Cleansparkplugs

X

Checkfuelline,hoseclamps

andfueltank

X

Oilleakinspection

X

Sparkarrestor

X

Sediment cup

X

Clean inline fuel filter

X

Checkforunusual

noise/vibration

X

Checkandadjustvalve

clearance(.15mmintake,

.2mmexhaust)

X

Prepare unit for Storage

Prepare unit for storage if it is to remain idle for more then 30

days

* The engine oil must be changed after the first 20 hours or operation. Thereafter change oil every

100 hours of operation or monthly, whichever comes first.

(1)Performmorefrequentlyindustyorhumidconditions

SPARK PLUG CONDITION CHECK

• Removethesparkplugforinspection

• AlwaysuserecommendedplugseeSpecifications

• Setgaptospecification,seeSpark Plug under Maintenance Standards.

1. Normal Plug – Slightly rounded electrodes with light coat of ashy brown deposits indi-

cate normal wear and a healthy engine.

2. Oil Fouling –Wetoilyfilmwillpreventtheplugfromsparking.Thisconditionsignals

worn valves or piston rings. This condition can be caused by running the engine in

thechokeposition.Checkvalvesandpistonrings,overhaulifneeded.Replacespark

plug.

3. Carbon Fouling–Blackdrysootcoveringtheelectrodesindicatesincompletecom-

bustion.Thiscanbearesultofweakignitionorarichmixture.

a.Checkcarburetoradjustment,adjustspeedifneeded.

b.Checkairfilter,cleanifneeded.

4. Gap Bridging – A combustion particle lodged between the electrodes carries current

across the gap. This does not normally signal engine problems elsewhere.

5. Whitened Electrodes – This is evidence combustion is too hot and there is overheat-

ing. This can result from too lean fuel mixture.

a.Make sure spark plug is correct type, see Spark Plug under Maintenance

Standards.

b. Ignition timing malfunction. Set ignition air coil gap, see the Flywheel Ignition

Adjustment section.

6. Excessive Wear – Plug worn to the point of having encrusted deposits and thin

rounded out electrodes. Replace plug.

WARNING: Hot surfaces. Risk of burn. Engine and surrounding parts are very hot, do not

touch. Allow engine to cool prior to servicing.

A dirty air cleaner will restrict airflow to the carburetor. To prevent carburetor mal func tion,

service the air filter regularly. Service more frequently when operating the generator in

extremely dusty areas.

WARNING: Using gasoline or flam mable solvent to clean the filter element can cause a

fire or explosion.

WARNING: Risk of fire. Do not operate without air filter.

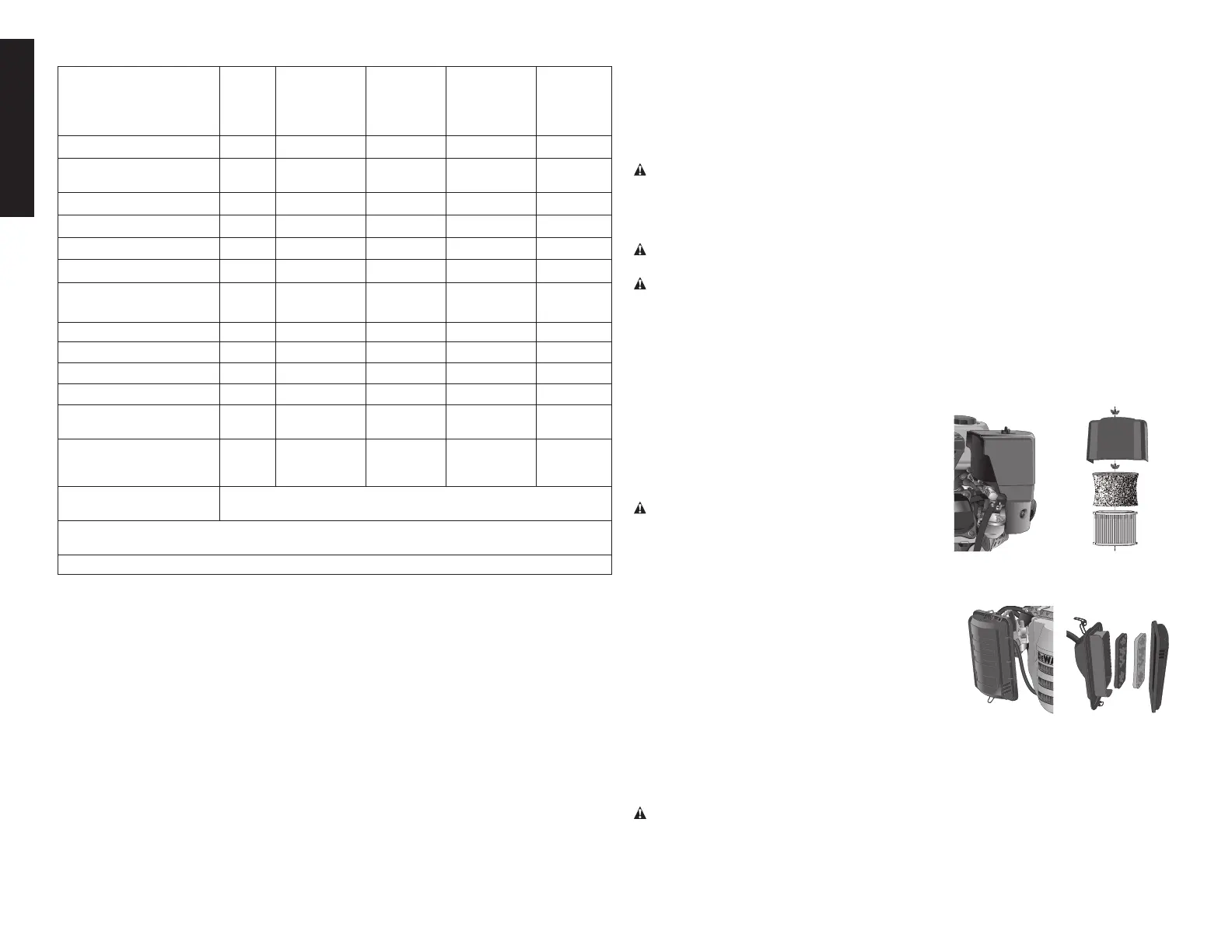

TO CLEAN THE ELEMENTS

(DW168F-2E, DW177F-E, DW168F-2H, DW177F-H)

1. Remove the wing nut and the air filter cover.

2. Remove the second wing nut and remove the filter.

3. Remove the foam-type pre-filter from the filter.

4. Inspect foam and paper elements. Replace them if damaged.

TO CLEAN THE ELEMENTS

Foam element: Wash element in warm, soapy

water. Then saturate it in clean engine oil.

Squeezetheelementtoremoveexcessoil.

Paper element: Clean element by tapping

gently to remove dust. Use compressed air to

blow off dust.

WARNING: When using compressed air, user

always must wear eye protection that conforms to

ANSI Z87.1. (CAN/CSA Z94.3).

Never use oil. Always blow the element from the

inside.Ifusingcompressedairkeeptheairpressurelessthan30psi.

Place the foam pre-filter over the paper element and reinstall it onto the engine.

(DW168F-2F, DW177FD-F, DW188F)

1. Unsnap the air filter cover clips and remove

the air cleaner cover.

2. Remove the elements from air filter.

3. Wash elements in warm soapy water and

rinse thoroughly. Allow the elements to dry

thoroughly.

4.Soak the elements in clean engine oil and

squeezeouttheexcessoil.NOTE: Theenginewillsmokeduringinitialstart-upiftoo

much oil is left in the elements.

5. Reinstall the air filter elements and snap air filter cover in place.

WARNING: Hot surfaces. Risk of burn. Engine and surrounding parts are very hot, do

not touch. Allow engine to cool prior to servicing.

TO CHECK OIL

1. Place unit on a flat level surface.

Loading...

Loading...